Chopped Strands for BMC

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 kg

- Supply Capability:

- 100000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description of Chopped Strands for BMC

Chopped Strands for BMC are compatible with unsaturated polyester, epoxy resin and phenolic resins.

The end-use applications include transportation, building & construction, electronic & electrical, mechanical, and light industry

Features of Chopped Strands for BMC

Low viscosity and excellent flowability of the BMC paste

Low static and low fuzz, fast and good dispersion in resins

Good processing and excellent mechnical properties

Specification of Chopped Strands for BMC

Product No. | Nominal Chopped Length(mm) | Product Features | Resin Compatibility | Applications |

562A | 3,6,9,12 | Extremely low resin demand, delivering low viscosity to BMC paste | Unsaturated polyester, vinyl ester and epoxy resins | Suitable to manufacture high fiberglass loading products with complex structure and superior color, for example, ceiling tiles and lampshade. |

552B | 3,6,9,12 | High impact strength; High LOI rate | Unsaturated polyester, vinyl ester and epoxy resins | Used in automotive parts, civilian electrical switches, sanitary ware and other products requiring high strength. |

558 | 3,6,9,12 | Good strand integrity, low static and fuzz, Fast and uniform distribution in resins, excellent mechanical and processing properties | Rubber and Phenolic resin | Used to manufacture various brake shoe facings, clutch facings, and friction plates. |

Storage of Chopped Strands for BMC

Unless otherwise specified, fiberglass products should be stored in a dry, cool and rain-proof area. It is recommended that the room temperature and humidity should be always maintained at 15 Deg.C-35 Deg.C and 35%-65% respectively.

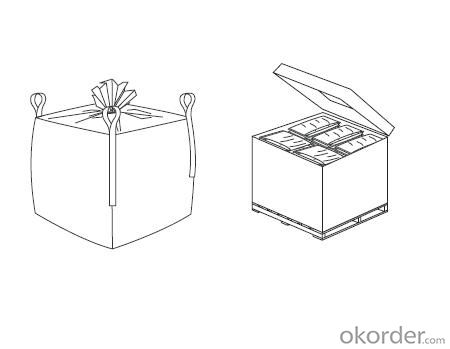

Photo of Chopped Strands for BMC

- Q:HS code for alkali-free glass fiber yarn

- The HS encoding the alkali-free glass fiber roving yarn is 70191200 and chopped yarn, spinning and Chinese HS EU tariff as follows, S and Z. Spun yarn is a spinning twist E-glass fiber. My question is whether it is yarn or spun yarn. If it is yarn, it would be twistless.

- Q:What is glass fibre reinforced plastic

- It can pass through the electromagnetic wave. It is made of synthetic resin and glass fiber through the composite process with good electrical insulation, high strength, and easy coloring. Glass fiber reinforced plastic is a new functional composite material used in different field with light weight, good instantaneous high temperature performance and thermal insulation. Glass?reinforced?plastics has a wide variety with slow heat transfer(also known as glass fiber reinforced plastic, internationally recognized abbreviation is GFRP or FRP).

- Q:What does fireproof bag used for ?

- The outer layer is made of glass fiber twistless roving and its inner layer is filled with special refractory, thermal insulation and expanding materials, which can expand in high temperature and solidified so as to form a sealing layer for the purpose of preventing fire spreading.

- Q:Specific classification and application of glass fiber

- The excellent resin infiltration and permeability: Glass, in general, is hard and fragile. The warp and weft density is decided by yarn structure and texture. It is suitable for all kinds of spray gun and fiber conveying system. Due to its super strength, it can be used for producing packaging sheet and sports equipment. Twistless roving need to be soaked into resin paste with high content of pigment. The requirement that chopped?strand should be used to enhance thermoplastic?plastics is suitable for alkali free glass fiber.

- Q:How to maintain the GRC exterior wall decoration components?

- According to DST, The texture of GRC wall decoration component must be alkali resistant glass fiber for reinforcement with right angle.

- Q:How to make glass fiber pipe

- If you ask what is the glass fiber sleeve such as epoxy or phenolic tubes, this is a complex question.

- Q:Production process of glass fiber tube

- The tube is made in continuous movement of mandrel. It should be feed into steel mould fixed in bearing. After continuous filament winding and centrifugal casting process finishes,the number of pipe manufacturers using reciprocating fiber winding process is more than that of other two production technology. After the resin in products has been solidified, you should inject unsaturated resin with catalyst at the one side of steel mould. This process is that pipe passes through a feeding station whcih aims to supply resin presoak twistless roving. There are mainly three manufacturing techniques of glass fiber pipe. Reciprocating fiber winding technology (belonging to the fixed length method). The main material includes glass fiber reinforced materials and sand. Auxiliary angle (wingding angel) is controlled by the ratio of impregnating vessel movement speed and mandrel rotate speed. Pipe usually solidifies under high temperature. With the help of centrifugal force, its applicability is very good. Continuous filament winding process(belongs to continuous method). Impregnating vessel movement is controlled by computerization machine. With the number of the layers increases gradually, inner tube form a smooth plane due to the centrifugal force and mandrel gets out of glass?reinforced?plastics pipe. Centrifugal casting process (belonging to the fixed length method). Tube made in this way, is also known as glass fiber reinforced plastic sand pipe. Reciprocating filament winding process In this process

- Q:What is the difference glass fiber roving and fine yarn ? Does the equipment used for production have any difference.

- 6 microns non-alkali, 9 micron twistless roving (bulk yarn), 80 alkali , 30 twist roving ans 21 medium alkali. It is a glass fiber integrated production enterprises combined management, scientific research and development. The company has advanced production equipment and strong technical force. Main production includes 30 alkali-free glass fiber yarn and 40 fine yarn with annual production of 1500 tons.

- Q:Can glass fiber be used for cement components

- Glass fiber is used as reinforced component is good. It features with weather resistance, acidproof and alkali resistant.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Chopped Strands for BMC

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 kg

- Supply Capability:

- 100000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords