Chinese Factory Glass Wool Blanket for Roofing and Wall

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m²

- Supply Capability:

- 10000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Glass Wool Insulation for Roofing

INTRODUCTION

In the field of insulation materials, weare mainly specializing in Glass wool products, including blankets, boards andpipes. The advantage of this material is numerous: noncombustible, nontoxic,and resistant to corrosion. It has low weight, low thermal conductivity, stablechemical property, low moisture rate and good hydrophobicity. These productshave been widely used in heat preservation, thermal insulation and soundabsorption in construction, chemical industry, electronic industry, electricpower, metallurgy, energy industry, and communication. High density panelslaminated with facing can be used for Air-conditioning duct system.

The Kinds of Glass Wool Insulation

* glass wool blanket plain or with Aluminum foil -clad(Kraft paper or white PVC/WPSK)

* glass wool board

* glass wool pipe

Our Advantage

* Short delivery time

* Origin of China, FROM A / E/ F

* Stable good quality with competitive price (CE certificate)

TECHNICAL DATA

Item | Unit | Index |

Density | Kg/m3 | 10-100 |

Average Fiber Diameter | μm | 5-7 |

Water Content | % | ≤1 |

Grade of Combustibility | Non-Combustible Grade A | |

Reshrinking Temp | ℃ | ≥250 |

Thermal Conductibility | w/m.k | 0.038-0.06 |

Hydrophobic | % | ≥98 |

Moisture Rate | % | ≤5 |

Noise Resistant Coefficient (NRC) | 0.75 | |

Slag Inclusion Content | % | ≤0.3 |

CE CERTIFICATE

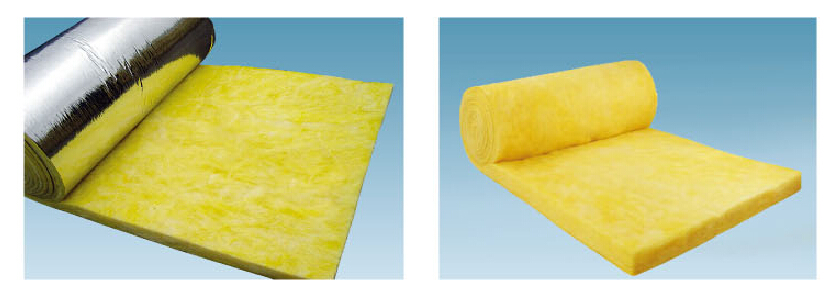

Glasswool Blanket

Introduction

The glass wool blanket is applied for largelaying area. Besides the character of thermal insurance, it also has theperformances of shock absorption and acoustical isolation, especially for middleor low frequency sound. It also can cancel the noise and improve workingenvironment.

The glass wool blanket with aluminum foilsurface has good capability of heat radiation protection.

TechnicalData

Item | Unit | Index |

Density | Kg/m3 | 10-32 |

Thickness | mm | 25-150 |

Width | mm | 600-1200 |

Length | mm | 10000-30000 |

Note: Product with special specificationcan be made to order.

Both unfaced and faced felts can beprovided.

Application

This material can be freely cut inconstruction according to the shape required, mainly used in room,noise-canceling system, transportation, refrigerators and household electricappliances for noise canceling.

The blanket with aluminum foil is suitablefor high temperature shops, control room, inner wall of the machine shops, roomseparating and inner liners.

Package

Normal packing: Each roll is wrapped withvacuum plastic bag, and then in PE woven bag.

Special required package like PE BAG and PESHRINKED BAG can be made with additional charge.

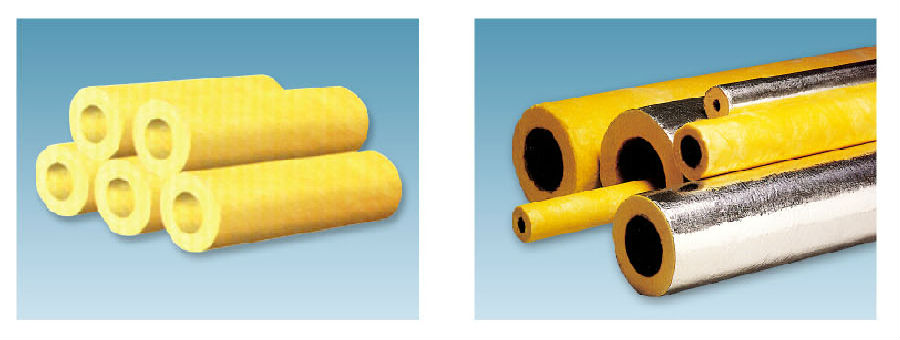

Glasswool Pipes

Introduction

As this material has the characters ofwater-proof, anti-corrosion and mildewing-proof, glass wool pipe is good atstopping condensation and freezing of the pipes.

TechnicalData

Item | Unit | Index |

Density | Kg/m3 | 48-96 |

Thickness | mm | 25-90 |

Diameter | mm | 18mm-529mm(3/4 inch to 21 inch) |

Length | mm | 1 000,1 200 |

Note: Product with special specificationcan be made to order.

Both unfaced and faced felts can beprovided.

Application

It is widely used in building, heating powerpipes, air conditioning and refrigerators for thermal insurance, such as hotwater pipes, steam pipes, electric power, petroleum and chemical industries.

Glass wool pipe faced with Alum Foil can beapplied to the surface for preventing moisture and radiation.

Package

Reasonable pieces will be packed withplastic bags or carton box, and then into container.

Glasswool Boards

Introduction

Glasswool board is a kind of plate productwith fixed strength after hot-setting of the centrifugal glass wool. It hasexcellent thermal insurance performance in the environment of both high and lowtemperature.

TechnicalData

Item | Unit | Index |

Density | Kg/m3 | 24-96 |

Thickness | mm | 20-100 |

Width | mm | 600-1 200 |

Length | mm | 1 200,2 400 |

Note: Product with special specificationcan be made to order.

Both unfaced and faced felts can beprovided.

Application

It is mainly used for the partition wall inthe high-grade building, such as ceiling, air conduit and inner wall forthermal insurance, machine shops for noise absorption, and metal ceiling forcontrol of moisture.

High density panels with laminated facingcan be used for Air-Conditioning Duct System.

Package

Reasonable pieces will be packed withplastic bags, and then into container.

- Q:What are the differences between glass wool and rock wool in terms of thermal insulation?

- If the temperature is higher than 300 degrees, the rock wool boards are better. The operation life of glass wool at high temperature is short, and the price of which is higher than that of rock wool. Galvanized board can be used as protective layer for its long operation life but it rusts easily and is not so beautiful. The aluminium plate has a short operation life and it damages and deforms easily.

- Q:During the construction of steel structure, should the aluminum foil of glass wool be directed indoors or outdoors? Why?

- The aluminum foil is under the glass wool. Do you understand me?

- Q:Can glass wool be used in exterior wall for thermal insulation?

- The tensile property of external wall thermal insulation materials is entirely determined by unit weight of thermal insulation materials and the mixture of binder with rock wool.

- Q:what's the price of high temperature resistance glass wool?

- Hello the different thickness and unit weight of the glass wool has different prices , generally a few dollars for each square meter, then if you are from Hebei, there are many companies have this products in Langfang, you can go there to consult. Price depends on how much K you need, that is, the number of density, the current mill price is around 2500 for one ton.

- Q:What is the difference between quartz wool and glass wool?

- Hello! I'm glad to answer your question! Glass wool is made by natural minerals such as quartz, dolomite, feldspar, limestone coupled with soda ash, borax and other auxiliary materials ... Glass wool is a fine fibrous material through drawing, blowing or swing of external force in melting state. Glass wool is an inorganic fiber. It has the following basic characteristics: ① It has good thermal insulation property at high and low temperatures. ② It is noncombustible without producing harmful gases, so it is designated as "legal non-combustible material" by various countries. ③ It has uniformly elastic restoring force. ④ Its moisture absorption rate is small under humid conditions. ⑤ Its coefficient of linear expansion is small. ⑥ It has low aging rate, able to remain the original performance after long-term use. ⑦ It has good machinability. Asbestos product is produced through the process that thining slate fibers by chemical beam to make them become slurry structure, and then sizing it at high temperatures. This product is characterized by lowest aging, non-degenerating, poisonless and tasteless, light weight and low thermal conductivity, etc. In addition, it is easy to construction, able to be cut freely and packaged based on types without irritating skin and wear and tear in construction and other advantages. Hope it will help you.

- Q:Glass wool can be used at zero degrees

- There are alkali superfine glass wool felt temperature: -100 ~ 450 ℃

- Q:What's the necessary performance tests lass wool used for steel structure need to do?

- Generally it doesn't need to do the experiment, but some party A will demand for thermal insulation test, you can ask the local supervisor for samples manual and show it to party A, there is no test on steel structure columns.

- Q:Why does glass wool turn black when exposed to heat? Wether it will ffect the thermal insulation effect.

- The burning like alcohol lamp uses glass wool as the substrate. There are two possibilities to take alcohol lamp to do experiment, which containing organic substances. 2. 1, High temperature oxidation. I produce aerogel thermal insulation felt, and I have seen that the charcoal ash produced is attached to the glass wool. It has some impact on thermal insulation effect, but the impact is small.

- Q:Which one among polystyrene?boards, rock wool boards and glass?wool?boards is the best materials for external wall thermal insulation?

- Polystyrene?boards are better in terms of external wall thermal insulation materials but now polystyrene?boards are not allowed to use. Rock wool and glass wool can be used, but they need good waterproofing treatments.

- Q:What are the standards of glass wool board?

- The national standard of rock wool board for exterior wall in construction is GB / T25975-2010, rock wool board for curtain walls in construction is GB / T25975-2005, and industrial rock wool board is GB / T11835-2007. The above-mentioned criteria are the standards of using rock wool products in various industries! Rock wool board is specifically designed and produced for exterior thermal insulation thin plastering system. It can be applied to the cosntruction of concrete or brick based buildings or thermal insulation or energy-saving of the exterior walls of he existing buildings; Wherein rock wool belt for thermal insulation of exterior walls can also serves as fire buffer zone and it can be used with thermal insulation material whose combustion performance is below A level to improve the fireproof function of the exterior walls of the building.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Chinese Factory Glass Wool Blanket for Roofing and Wall

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m²

- Supply Capability:

- 10000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords