China VFD Frequency Inverter

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications

1.220V Single Phase Variable Frequency Drive 2.2KW

2.Advanced control technology

3.Easy to operate

220V Single Phase Variable Frequency Drive 2.2KW

General

CNBM frequency inverter is a high-quality, multi-function,

low-noise variable frequency drive which is designed, developed and manufactured according to international standards.

It can meet different needs of industrial conditions.

The inverter applies advanced control technology of space voltage vector PWM, with functions of constant voltage control, power-off restart, dead zone compensation, automatic torque compensation, online modification parameter, high-speed impulse input, simple PLC and traverse.

Product Name:CMAX-VCG15/P18.5T3 ~ CMAX-VCG18.5/P22T3

Application

Textile: coarse spinner, spinning frame, wrap-knitting machine, loom, knitting machine, silk-spinning machine, etc.

Plastic: extruder, hauling machine, decorating machine, etc.

Pharmacy: mixer, roaster, etc.

Woodworking: engraving machine, sander, veneer peeling lathe, etc.

Papermaking: single type papermaking machine, etc.

Machine tool: non-core grinding machine, optical lens grinding machine, cutting mill, etc.

Printing: cloth-washing machine, dye vat, etc.

Cement: feeder, air blower, rotary furnace, mixer, crusher, etc

Fan and pump: kinds of fans, blowers and pumps

Specification

Item | Specification | |

Input | Input voltage | 220/380V±15% |

Input frequency | 47~63Hz | |

Output | Output voltage | 0~input voltage |

Output frequency | 0~600Hz | |

Peripheral interface characteristics | Programmable digital input | 4 switch input, 1 high-speed impulse input |

Programmable analog input | AI1: 0~10V input AI2: 0~10V input or 0~20mA input, | |

Programmable open collector output | 2 Output (3.7kW and above: 1 Open collector output) | |

Relay Output | 1 Output (3.7kW and above: 2 Relay output) | |

Analog output | 2 Output, one is 0~10V, another is 0~20mA or 0~10V | |

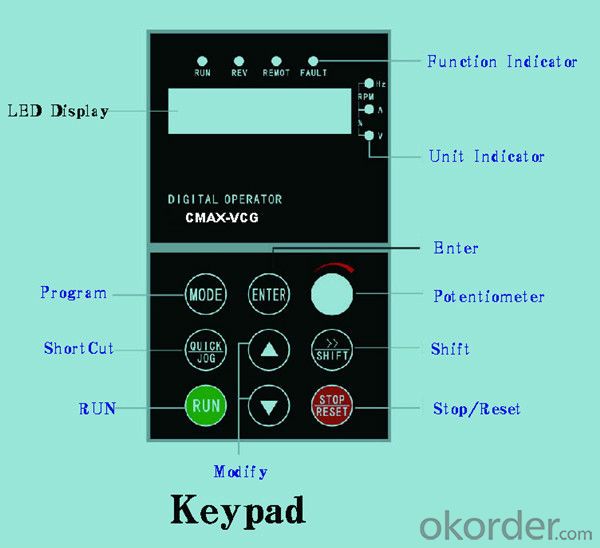

Keypad | Display:5-digit 8-section LED (Red), 2 indicators; parameter setting: 8 keys (including multi-function hot key ), 1 potentiometer | |

Technical performance characteristics | Control mode | All digital space voltage vector SVPWM algorism |

Overload capacity | G purpose: 150% rated current 60s P purpose: 120% rated current 60s | |

Speed ratio | 1: 100 | |

Carrier frequency | 1.0~10.0kHz | |

Torque compensation | Linear, multi-point, 1.3th power, 1.7th power, 2.0th power reduced torque; Compensation voltage range: automatic compensation and manual compensation 0.1~10% | |

Automatic voltage adjustment | It can automatically maintain output voltage constant when grid voltage fluctuates. | |

Automatic current adjustment | When the current is over current limit, under clocking automatically limits output current. | |

Function characteristics | Frequency setting mode | Keypad digital analog input, keypad potentiometer, impulse frequency, communication, multi-step speed and simple PLC, PID setting and so on, switch-over of setting modes. |

Simple PLC, multi-step speed control | 16-step speed control | |

Special function | Traverse control, length control, time control | |

QUICK/JOG key | User-defined multi-function hot key | |

Protection function | Over-current, Over voltage, under-voltage, over-heat, phase failure, over-load and motor over-load | |

Working condition | Installation site | Indoor, altitude of less than 1km, dust free, non-corrosive gases, no direct sunlight |

Application environment | -10°C~+40°C, 20~90%RH (no dew) | |

Vibration | Less than 0.5g | |

Storage temperature | -25°C~+65°C | |

Installation type | Wall-mounted type, floor cabinet type | |

Cooling mode | Air-forced cooling | |

- Q:That is, some parameters of the inverter, such as torque, current, frequency, etc., are displayed on the Kingview software interface, but not through the PLC. The idea that the MODBUS protocol between SIEMENS and 200PLC has never been successful before, so that's the idea of the ABB. If it can be achieved,Is it necessary to write the script program on the Kingview, and what problems should I pay attention to when using the MODBUS protocol in Kingview software?The problem is a little bit more, I hope the experts teach me this rookie! Thank you

- ABB converter supports MODBUS protocol, can be directly connected to the ModbusRTU in your choice of Kingview, device configuration, set up converter address directly in Kingview read the corresponding parameters can be

- Q:How does the frequency converter fit the brake unit and the brake resistor?!

- To calculate how much energy consumption, can be converted into electric current, to select the brake unit. You can also choose the braking resistance (to consider resistance temperature characteristics to choose), then select the brake unit with matching (see manufacturer manual).

- Q:Can the motor with frequency converter directly wave the insulation?

- The use of motor inverter drive, if the measurement will not disconnect the motor and inverter, tramegger issued a "high voltage" will spread through the winding inverter inside, will lead to some components breakdown within the inverter a damaged, because some components although the internal current is higher but the degree of pressure will be very limitedTherefore, in shaking the test of the use of inverter motor insulation, the inverter and motor connection is broken after the start, you can ensure that the frequency converter will not be damaged.

- Q:What does "frequency" in household appliances mean?

- Microwave frequency with high frequency power to the magnetron necessary boost drive, power supply structure, furnace space more spacious, new microwave oven can adjust power, and choose the best food according to different heating methods, shorten the time, reduce power consumption; lighting, fluorescent lamp with high frequency lighting, can improve the luminous efficiency, energy saving easy, no flicker, dimming, frequency adjustable ballast, compact and lightweight. Frequency conversion technology is bringing a new revolution to all kinds of home appliances, and will bring greater gospel to users. In the future, the frequency conversion technology will develop with the development of power electronic devices, new power conversion topology circuits, filtering and shielding technology. Home solar power generation systems will also add new energy to home appliances.

- Q:What is the difference between frequency converter and servo driver?

- The general use of the situation, such as high-speed, high-precision positioning equipment, servo, high power speed control using frequency conversion.Like the central air conditioning system, elevators and so on, many places use frequency conversion; like the textile machine, the placement machine, the plug-in machine uses the servo. In fact, many cases are used in conjunction with the two systems, according to the needs of the design arrangements.

- Q:What is called vector converter?

- The vector converter technology is based on the DQ axis theory. Its basic idea is to decompose the current of the motor into D axis current and Q axis current, among which DVector converter

- Q:How does the frequency converter change the voltage and change the speed of the motor?

- Change the motor frequency converter, V/F control mode in changing the motor frequency at the same time according to the proportion of changing the voltage of the motor, the speed and frequency of the motor is proportional to the relationship, so it changes the motor speed.

- Q:What is the difference between inverter energy consumption braking and motor energy consumption braking?

- A direct current is generated in the stator winding so that a fixed magnetic field is generated. At this point, the rotor cuts the magnetic field lines in the direction of rotation, resulting in a braking torque. Because the braking method is not like regenerative braking (using frequency converter), the energy generated by braking is fed back to the grid, but the energy is dissipated by the motor alone, so it is called energy consumption braking. The utility model is also used for braking by direct current in the stator winding, so the energy consumption braking is called DC injection braking. By using the backward switch Q to return the point voltage back to the grid, the armature current will become a copy, and the current will be of the same magnitude, resulting in a great braking torque of the motor, which will stop the motor.

- Q:What is the difference between a frequency converter and a servo controller?

- Servo system: 1 servo drives in the premise of the development of frequency conversion technology, the current loop in the internal drive, speed loop and position loop (inverter without the ring) of algorithm operation and control technology is more accurate than the general frequency, but also in the function than the traditional servo many powerful, the main point can accurate position control. To control the speed and position of the pulse sequence controller sends the (of course there are also some integrated servo control unit or by bus communication way directly to set the parameters of position and velocity in the drive), drive the internal algorithm and faster and more accurate calculation and better performance of electronic devices to be more superior to converter. 2, motor servo motor of the material, structure and machining process is much higher than that of the AC motor drive inverter (general AC motor or constant torque, constant power and other types of motor), that is to say when the power driver output current and voltage and frequency change quickly, the servo motor can generate action response according to the change power changes, response and anti overload capacity is much higher than that of AC motor inverter drive motor, fundamental serious differences is two different performance. That is to say, not the inverter can not change the power supply signal, but the motor itself can not respond, so in the frequency of the internal algorithm settings, in order to protect the motor to do the corresponding overload settings. Of course, even if the output power of the inverter is not limited, some high-performance inverters can directly drive the servo motor!

- Q:What is a frequency converter?

- VVVF: change voltage, change frequency CVCF: constant voltage, constant frequency. AC power supplies used in various countries, whether for homes or factories, have voltages and frequencies of 400V/50Hz or 200V/60Hz (50Hz), and so on. Normally, a device that changes the alternating current of voltage and frequency to a voltage or frequency variable alternating current is called a frequency converter". To produce a variable voltage and frequency, the device first transforms the alternating current of the power source into direct current (DC).

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

China VFD Frequency Inverter

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords