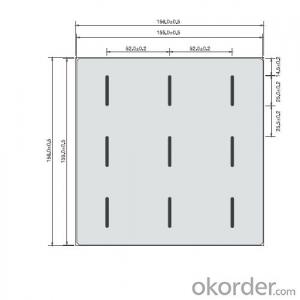

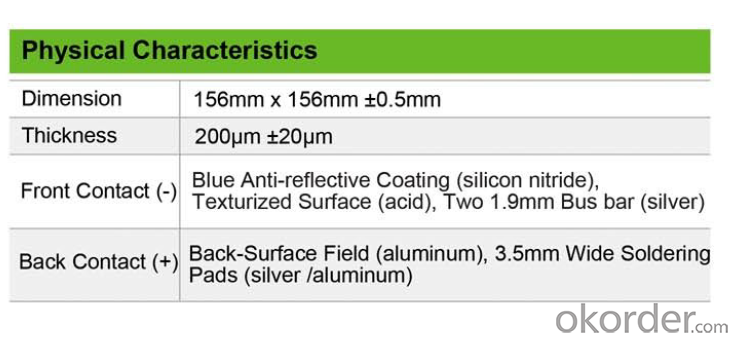

China Solar Cells Poly 156x156mm with High Conversion Efficiencies

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10 watt

- Supply Capability:

- 10000 watt/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

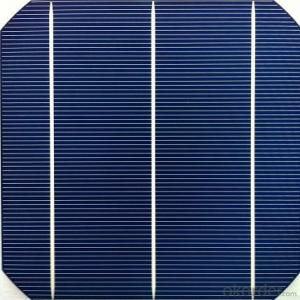

our cells special features:

1. High conversion efficiencies resulting in superior power output performance

2.Outstanding power output even in low light or high temperature conditions

3.Optimized design for ease of soldering and lamination

4.Long-term stability,reliability and performance

5.For 156P poly cells with high efficiency in photovoltaic conversion 16.3%-17.5%.

6.Low inverse current, high shunt resistance and high dependability.

7. Our poly cells efficiency include: 17%-18%.

Conversion of different solar materials

Solar photovoltaic power generation more important seats in the world's energy consumption in the near future, not only to replace part of conventional energy, are more likely to become the main body of the world's energy supply.

Solar cell is a light energy into electrical energy components. Low-cost high-efficiency solar cell photovoltaic technology long chase the target, it is hard to compete for each enterprise technology territory.

Solar cells market applications more wide-ranging and diversified to meet the various needs of photovoltaic products are constantly available, in addition to large-scale grid-connected PV power plant outside, combined with the construction of photovoltaic systems, small-scale PV systems, off-grid PV systems, also fast rise. The cost of solar cells and photovoltaic systems continued to decline and approximate cost of conventional power generation, is still the subject of photovoltaic industry development, and solar cells will continue to walk in high-efficiency, low-cost way.

We are familiar with crystalline silicon cells into single crystal and polycrystalline, except that the silicon wafers. Monocrystalline wafers made of polysilicon raw material crystal pullers pull into a bar and then sliced into monocrystalline, polycrystalline silicon film is made of polysilicon through ingot casting furnaces made of polysilicon ingots and then sliced. However, polycrystalline silicon photovoltaic cells still dominant the market currently.

The basic structure of a solar cell is to use a P-type and N-type semiconductors are joined together. The most important parameter is the photoelectric conversion efficiency. In the single-crystal battery, the current level of industrialization of developed N-type monocrystalline cells in about 21% -24%, the level of domestic industry P-type monocrystalline cells is about 18.7% -19.2%, 19.2% in overseas -20% or so. Polycrystalline battery’s industrialization level is the 17% - 17.5%. Here are edited from the N-type monocrystalline cells, P-type monocrystalline cells, polycrystalline cells are three types of contrast, certified technological frontier representatives listed below.

- Q:Which brand of the solar cells is sold with the lower price on the market? Which brand is more practical for the countryside?

- SMI is a professional solar cell provider in the current market, I am sure they can provide the solar cells with low price as you expected.

- Q:What can be used as the materials for solar cells?

- Some kind of semi-conductor is one of the materials.

- Q:What is the typical warranty for solar cells?

- The typical warranty for solar cells ranges from 10 to 25 years, depending on the manufacturer and type of solar cell.

- Q:How are solar cells affected by temperature?

- Solar cells are negatively affected by high temperatures as they experience a decrease in efficiency due to increased resistance and thermal losses. This is because higher temperatures lead to increased electron-hole recombination rates and decreased open-circuit voltage. However, low temperatures can also reduce solar cell performance due to decreased conductivity and increased series resistance.

- Q:How do solar cells perform in areas with high levels of industrial emissions?

- Solar cells can still function effectively in areas with high levels of industrial emissions. While industrial emissions can potentially increase air pollution and reduce sunlight, solar cells are designed to convert both direct and indirect sunlight into electricity. Though the efficiency of solar cells might be slightly reduced due to decreased sunlight availability, proper maintenance and cleaning can help mitigate any potential negative impact on their performance.

- Q:Can solar cells be used in educational institutions?

- Yes, solar cells can be used in educational institutions. They can be used to generate clean and renewable energy, which can help reduce the institution's carbon footprint and energy costs. Additionally, solar cells can serve as an educational tool, allowing students to learn about sustainable energy sources and the importance of environmental conservation.

- Q:Can solar cells generate electricity at night?

- No, solar cells cannot generate electricity at night as they rely on sunlight to produce electricity.

- Q:Can solar cells be used for powering electric fences?

- Yes, solar cells can be used for powering electric fences. Solar cells convert sunlight into electrical energy, which can be stored in batteries and used to power electric fences. This provides a sustainable and environmentally-friendly solution for powering fences in areas where access to grid electricity is limited or expensive.

- Q:Can solar cells be used for powering data centers?

- Yes, solar cells can be used for powering data centers. Solar energy can be harnessed through photovoltaic cells and converted into electricity, which can then be used to power data centers. This renewable energy source is increasingly being adopted by data centers to reduce their carbon footprint and energy costs.

- Q:What materials are commonly used to make solar cells?

- The most commonly used materials to make solar cells are silicon, cadmium telluride, and copper indium gallium selenide.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

China Solar Cells Poly 156x156mm with High Conversion Efficiencies

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10 watt

- Supply Capability:

- 10000 watt/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords