china good 35.8 /a53/a106 /a179 seamless pipe,schedule 40 steel pipe seamless steel pipe

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 300000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1、Structure of seamless pipe,schedule 40 steel pipe seamless steel pipe:

Seamless pipe is formed by drawing a solid billet over a piercing rod to create the hollow shell. As the manufacturing process does not include any welding, seamless pipes are perceived to be stronger and more reliable. Historically seamless pipe was regarded as withstanding pressure better than other types, and was often more easily available than welded pipe.

2、Main Features of seamless pipe,schedule 40 steel pipe seamless steel pipe:

• High manufacturing accuracy

• High strength

• Small inertia resistance

• Strong heat dissipation ability

• Good visual effect

• Reasonable price

3、seamless pipe,schedule 40 steel pipe seamless steel pipeSpecification:

Standard | GB, DIN, ASTM ASTM A106-2006, ASTM A53-2007 | ||||||||||||||||||||||||||||||||||

Grade | 10#-45#, 16Mn fication:

10#, 20#, 45#, 16Mn | ||||||||||||||||||||||||||||||||||

Thickness | 8 - 33 mm | ||||||||||||||||||||||||||||||||||

Section Shape | Round | ||||||||||||||||||||||||||||||||||

Outer Diameter | 133 - 219 mm | ||||||||||||||||||||||||||||||||||

Place of Origin | Shandong, China (Mainland) | ||||||||||||||||||||||||||||||||||

Secondary Or Not | Non-secondary | ||||||||||||||||||||||||||||||||||

Application | Hydraulic Pipe | ||||||||||||||||||||||||||||||||||

Technique | Cold Drawn | ||||||||||||||||||||||||||||||||||

Certification | API | ||||||||||||||||||||||||||||||||||

Surface Treatment | factory state or painted black | ||||||||||||||||||||||||||||||||||

Special Pipe | API Pipe | ||||||||||||||||||||||||||||||||||

Alloy Or Not | Non-alloy | ||||||||||||||||||||||||||||||||||

Length | 5-12M | ||||||||||||||||||||||||||||||||||

Outer Diameter | 21.3-610mm | ||||||||||||||||||||||||||||||||||

Grade | 20#, 45#, Q345, API J55, API K55, API L80, API N80, API P110, A53B | ||||||||||||||||||||||||||||||||||

Standard | ASME, ASTM |

1) Material:20#(ASTM A 106/A53 GRB.API5LGRB,GB),45#,16Mn,10#.

2) Specification range:OD:21.3-610mm,WT:6-70mm,length:6-12m or according to the requirement of clients.

3) Excutive standards:GB,ASME API5L.ASTM A 106/A53,Despite of the above standards,we can also supply seamless steel pipe with standard of DIN,JIS,and so on,and also develop new products according to the requirements of our clients!

4) Surface:black lacquered,varnish coating or galvanized.

5) Ends:Beveled or square cut,plastic capped,painted.

6) Packing:bundles wrapped with strong steel strip,seaworthy packing.

4、Packaging & Delivery

Packaging Details: | seaworthy package,bundles wrapped with strong steel strip |

Delivery Detail: | 15-30days after received 30%TT |

5、FAQ of seamless pipe,schedule 40 steel pipe seamless steel pipe:

①How is the quality of your products?

Our products are manufactured strictly according to national and internaional standard, and we take a test

on every pipe before delivered out. If you want see our quality certifications and all kinds of testing report, please just ask us for it.

Guaranteed: If products’ quality don’t accord to discription as we give or the promise before you place order, we promise 100% refund.

②How about price?

Yes, we are factory and be able to give you lowest price below market one, and we have a policy that “ for saving time and absolutely honest business attitude, we quote as lowest as possible for any customer, and discount can be given according to quantity”,if you like bargain and factory price is not low enough as you think, just don’t waste your time.Please trust the quotation we would give you, it is professional one.

③Why should you chose us?

Chose happens because of quality, then price, We can give you both.Additionally, we can also offer professional products inquiry, products knowledge train(for agents), smooth goods delivery, exellent customer solution proposals.Our service formula: good quality+good price+good service=customer’s trust

SGS test is available, customer inspection before shipping is welcome, third party inspection is no problem.

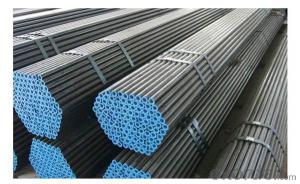

6、seamless pipe,schedule 40 steel pipe seamless steel pipe Images:

- Q:How are steel pipes used in the manufacturing of appliances?

- Steel pipes are commonly used in the manufacturing of appliances for various purposes such as transporting fluids, gases, and air within the appliance, providing structural support, and acting as conduits for electrical wiring. They are also used for creating ventilation systems and heat transfer mechanisms, ensuring efficient operation and durability of appliances.

- Q:What is the difference between steel pipes and copper-nickel pipes?

- Steel pipes and copper-nickel pipes differ in material composition and properties. Steel pipes are primarily made from iron and carbon, which provide strength and durability. They are suitable for various applications, including plumbing, construction, and industrial purposes. On the other hand, copper-nickel pipes are composed of a combination of copper and nickel, which offer excellent corrosion resistance and thermal conductivity. These pipes are often used in marine environments, desalination plants, and offshore oil and gas industries due to their ability to withstand saltwater corrosion. Overall, the main distinction lies in their composition and specific applications based on their unique properties.

- Q:How are steel pipes used in the manufacturing of irrigation systems?

- Steel pipes are commonly used in the manufacturing of irrigation systems as they provide durability, strength, and resistance to corrosion. These pipes are used to connect various components of the irrigation system, such as pumps, filters, valves, and sprinklers. They ensure the efficient flow of water, withstand high pressure, and can be easily customized to fit the specific requirements of the irrigation system.

- Q:Can steel pipes be used for underground heating systems?

- Yes, steel pipes can be used for underground heating systems. Steel pipes are commonly used for this purpose due to their durability, strength, and resistance to corrosion. They can effectively transport hot water or steam to provide heating in underground systems.

- Q:What are the different types of steel pipe flanges?

- There are several different types of steel pipe flanges, including slip-on flanges, weld neck flanges, socket weld flanges, threaded flanges, blind flanges, lap joint flanges, and orifice flanges. Each type has its own unique design and purpose, catering to specific applications and requirements in various industries.

- Q:How are steel pipes used in underground drainage systems?

- Steel pipes are commonly used in underground drainage systems due to their durability and strength. They are typically used to carry and transport wastewater and stormwater away from buildings and structures to a designated disposal area or treatment facility. The corrosion-resistant nature of steel pipes ensures a long lifespan, making them a reliable choice for underground drainage applications. Additionally, steel pipes can withstand high water pressure and are often used in larger diameter pipes to handle a higher volume of water flow.

- Q:Can steel pipes be used for underground pressure pipelines?

- Yes, steel pipes can be used for underground pressure pipelines. Steel pipes are known for their strength, durability, and resistance to corrosion, making them suitable for underground applications where pressure is present. Additionally, steel pipes can withstand high temperatures and external forces, making them an ideal choice for underground pressure pipelines.

- Q:What are the different standards for steel pipe manufacturing?

- There are several standards for steel pipe manufacturing, including ASTM (American Society for Testing and Materials), API (American Petroleum Institute), DIN (Deutsches Institut für Normung), and JIS (Japanese Industrial Standards). These standards define the specifications for various aspects of steel pipe production, such as dimensions, material composition, mechanical properties, and testing procedures. Compliance with these standards ensures the quality and reliability of steel pipes for different applications, ranging from construction and infrastructure to oil and gas industries.

- Q:How do you inspect steel pipes for defects?

- Inspecting steel pipes for defects involves a systematic approach that combines visual inspection, non-destructive testing (NDT) techniques, and specialized equipment. Here are the steps typically followed to inspect steel pipes for defects: 1. Visual Inspection: Start by visually examining the external surface of the pipe, looking for any visible signs of defects such as cracks, dents, or corrosion. Pay close attention to welds, joints, and areas susceptible to stress or damage. 2. Ultrasonic Testing (UT): Ultrasonic testing is commonly used to detect internal defects in steel pipes. It involves using ultrasonic waves that are sent into the pipe and then interpreted based on the echoes received. Any irregularities in the internal structure, like cracks or voids, can be identified and analyzed. 3. Magnetic Particle Inspection (MPI): MPI is a widely used technique to detect surface and near-surface defects such as cracks, seams, or other discontinuities. This method involves applying a magnetic field to the pipe and then applying ferromagnetic particles (usually iron-based) on the surface. These particles will accumulate and form visible indications at the areas of magnetic flux leakage caused by defects. 4. Eddy Current Testing (ECT): Eddy current testing is suitable for detecting surface and near-surface defects in conductive materials like steel. It involves inducing an alternating current into the pipe and monitoring the changes in the electrical currents induced by any defects present. These changes are then analyzed to identify and evaluate the defects. 5. Radiographic Testing (RT): Radiographic testing is performed by exposing the steel pipe to X-rays or gamma rays and capturing the resulting radiographic images. This technique allows for the detection of internal defects such as cracks, porosity, inclusions, or wall thickness variations. The radiographic images are then examined for any indications of defects. 6. Dye Penetrant Inspection (DPI): DPI is a method used to detect surface-breaking defects in steel pipes. It involves applying a liquid dye on the surface, which penetrates into any surface cracks or flaws. After allowing the dye to seep in and adequately react, excess dye is removed, and a developer is applied to draw out the dye from the defects, making them visible. 7. Pressure Testing: Pressure testing involves pressurizing the steel pipe to a predetermined level and monitoring for any pressure drops or leaks. This test ensures that the pipe can withstand the required pressure without any structural defects. It is important to note that the inspection technique used depends on various factors, such as the type of defect being sought, the size and nature of the pipe, and the specific industry standards and regulations. Inspection professionals with expertise in NDT methods and equipment are typically employed to ensure accurate and reliable results.

- Q:Are steel pipes suitable for underground nuclear waste storage?

- Steel pipes are not suitable for underground nuclear waste storage. While steel is a strong and durable material, it is not resistant to corrosion when exposed to certain types of nuclear waste. Over time, the radioactive materials can corrode the steel pipes, leading to potential leaks and contaminating the surrounding environment. Additionally, steel pipes are not designed to withstand the extreme temperatures and pressures that can occur in nuclear waste storage facilities. Therefore, alternative materials such as corrosion-resistant alloys or concrete are typically used for underground nuclear waste storage to ensure the containment and isolation of the hazardous materials.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

china good 35.8 /a53/a106 /a179 seamless pipe,schedule 40 steel pipe seamless steel pipe

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 300000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords