China Best Selling VFD Frequency Drive Three Phase 380V

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 pc

- Supply Capability:

- 100000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications

1.220V Single Phase Variable Frequency Drive 2.2KW

2.Advanced control technology

3.Easy to operate

220V Single Phase Variable Frequency Drive 2.2KW

General

CNBM frequency inverter is a high-quality, multi-function,

low-noise variable frequency drive which is designed, developed and manufactured according to international standards.

It can meet different needs of industrial conditions.

The inverter applies advanced control technology of space voltage vector PWM, with functions of constant voltage control, power-off restart, dead zone compensation, automatic torque compensation, online modification parameter, high-speed impulse input, simple PLC and traverse.

Product Name:CMAX-VCG15/P18.5T3 ~ CMAX-VCG18.5/P22T3

Application

Textile: coarse spinner, spinning frame, wrap-knitting machine, loom, knitting machine, silk-spinning machine, etc.

Plastic: extruder, hauling machine, decorating machine, etc.

Pharmacy: mixer, roaster, etc.

Woodworking: engraving machine, sander, veneer peeling lathe, etc.

Papermaking: single type papermaking machine, etc.

Machine tool: non-core grinding machine, optical lens grinding machine, cutting mill, etc.

Printing: cloth-washing machine, dye vat, etc.

Cement: feeder, air blower, rotary furnace, mixer, crusher, etc

Fan and pump: kinds of fans, blowers and pumps

Specification

Item | Specification | |

Input | Input voltage | 220/380V±15% |

Input frequency | 47~63Hz | |

Output | Output voltage | 0~input voltage |

Output frequency | 0~600Hz | |

Peripheral interface characteristics | Programmable digital input | 4 switch input, 1 high-speed impulse input |

Programmable analog input | AI1: 0~10V input AI2: 0~10V input or 0~20mA input, | |

Programmable open collector output | 2 Output (3.7kW and above: 1 Open collector output) | |

Relay Output | 1 Output (3.7kW and above: 2 Relay output) | |

Analog output | 2 Output, one is 0~10V, another is 0~20mA or 0~10V | |

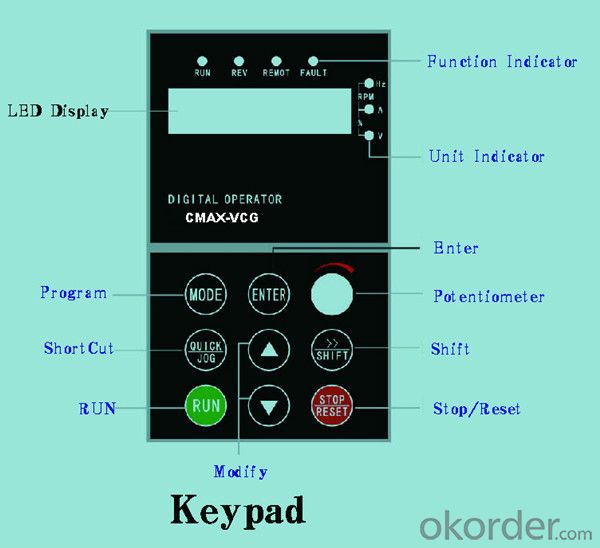

Keypad | Display:5-digit 8-section LED (Red), 2 indicators; parameter setting: 8 keys (including multi-function hot key ), 1 potentiometer | |

Technical performance characteristics | Control mode | All digital space voltage vector SVPWM algorism |

Overload capacity | G purpose: 150% rated current 60s P purpose: 120% rated current 60s | |

Speed ratio | 1: 100 | |

Carrier frequency | 1.0~10.0kHz | |

Torque compensation | Linear, multi-point, 1.3th power, 1.7th power, 2.0th power reduced torque; Compensation voltage range: automatic compensation and manual compensation 0.1~10% | |

Automatic voltage adjustment | It can automatically maintain output voltage constant when grid voltage fluctuates. | |

Automatic current adjustment | When the current is over current limit, under clocking automatically limits output current. | |

Function characteristics | Frequency setting mode | Keypad digital analog input, keypad potentiometer, impulse frequency, communication, multi-step speed and simple PLC, PID setting and so on, switch-over of setting modes. |

Simple PLC, multi-step speed control | 16-step speed control | |

Special function | Traverse control, length control, time control | |

QUICK/JOG key | User-defined multi-function hot key | |

Protection function | Over-current, Over voltage, under-voltage, over-heat, phase failure, over-load and motor over-load | |

Working condition | Installation site | Indoor, altitude of less than 1km, dust free, non-corrosive gases, no direct sunlight |

Application environment | -10°C~+40°C, 20~90%RH (no dew) | |

Vibration | Less than 0.5g | |

Storage temperature | -25°C~+65°C | |

Installation type | Wall-mounted type, floor cabinet type | |

Cooling mode | Air-forced cooling | |

- Q:What does "G" and "P" mean in the converter model?

- Frequency converter (frequency transformer) is usually the use of power semiconductor devices through the role of switching the power frequency to another frequency power control device. The main circuit of the inverter can be divided into two categories: voltage is DC voltage source converter for AC inverter, the DC circuit is the filter capacitor current is DC converter; current source for AC inverter, the DC circuit filter inductance.

- Q:Can the frequency converter 7.5KW take the motor with 11KW?

- Inverter 7.5KW can not take 11KW motor, so that may cause overload inverter.Usually, the frequency converter 7.5KW can take about 5KW motors.

- Q:Check the fault information is the power supply voltage instability, but other inverters are running well, what is the matter? Will there be any other parameters are not set correctly, thank you!

- To solve the problem, then check the original power of the line is loose, the power cables are quickly burnt, after fastening normal, thank you enthusiastic support, thank you!

- Q:I do mining equipment, recently I used ABB frequency converter to put into our equipment, but the problem of interference really gives me a headache! We have two pieces of equipment of SIEMENS S7-200 PLC, and is used in point to point protocol communication with each other, when the converter work PLC communication interference! There are monitoring equipment, converter work, there are a large number of snowflakes on the screen, simply do not see! Not even an internal phone! I've done well in grounding, but I still can't do it! Is there any master who can teach me a trick?

- You can try using the following methods:Solution of interference caused by circuit coupling:The PLC and monitoring equipment are powered by isolated transformers.

- Q:The frequency converter works with sharp noises. What's the process of converting electrical energy into mechanical energy?. The mechanism of sound making. Thank you

- There is a sharp sound can only prove that you have problems with frequency conversion, frequency conversion stable operation can only hear the sound of the fan slightly. Although we are engaged in frequency conversion, but let me tell you this mechanism, really can not say, you can use frequency conversion, and play to his limit, have been very difficult.

- Q:Surface grinder can add frequency converter, what are the advantages and disadvantages?

- The use of variable frequency speed control, you can simplify the gear, gearbox and other complex mechanical drag mechanism, high degree of automation, simple operation, easy maintenance.The frequency converter adopts the external terminal control, and the DC 0-10V signal issued by the numerical control system is fed into the frequency converter through the VI ACM terminal of the frequency converter, and the digital setting speed is controlled to the analog variable frequency output. The motor speed is controlled by the size of the voltage signal produced by the numerical control system.The frequency converter has voltage (DC0 - 10V), current analog input interface, and can be well matched with the control signal of CNC system.

- Q:Why does the frequency change when the frequency converter regulates the frequency?

- That's for sure. The curve of voltage and frequency should be set according to the load condition, but after the rated frequency of the motor, the voltage is kept at the rated voltage

- Q:What does the base frequency 60Hz represent in the inverter?

- How to set the frequency converter: inverter frequency parameter should be set to the rated frequency of the motor is set up, and not according to the load characteristic set, even if the selection is not suitable for motor load characteristics or parameters must also try to follow the motor, easy over-current or overload.

- Q:What's the role of an electric car, the part of a traditional car?

- Optimal energy utilization.The optimal utilization of energy is another basic requirement of electric vehicle, the control system can be as much as possible the use of energy, including the use of overheating and regenerative braking energy, make full use of limited energy. Ability feedback can implement this function. It includes two kinds of vehicle braking capability feedback and vehicle coasting ability feedback. In our state, the drive motor according to the operation of the generator, the vehicle kinetic energy into electricity, can play 3 roles: auxiliary braking; energy recovery to the power battery, thereby prolonging the vehicle mileage; in vehicle heating demand, can directly use this energy heating.

- Q:How much is the motor 90KW and the frequency converter selected?Colleagues suggest 110W?The cost will be higherIs it okay to choose 90KW?

- Motor 90KW, frequency converter, 90KW can be applied, but the frequency can not exceed the rated value of the motor. There are some occasions to live and use the frequency converter to speed up the motor, so it should be chosen a little larger, otherwise the inverter will be more loaded.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

China Best Selling VFD Frequency Drive Three Phase 380V

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 pc

- Supply Capability:

- 100000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products