Chemical Cross-linkable Low Smoke Zero Haogen Flame Retardant Polyolefin Compound

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 350 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Polyolefin:

1. Applications and cable specifications of Polyolefin:

Used for cross-linked and insulating wires and cables of apparatus and instruments, equipments and etc.

Type | Product | Application and Cable Specification |

YJZD90 | 90℃ Chemical cross-linkable, low-smoke, halogen-free and flame retardant POE compound | Used for cross-linked and insulating wires and cables of apparatus and instruments, equipments and etc. |

YJZD105 | 105℃ Chemical cross-linkable, low-smoke, halogen-free and flame retardant POE compound | Used for cross-linked and insulating wires and cables of apparatus and instruments, equipments and etc. |

YJZD125 | 125℃ Chemical cross-linkable, low-smoke, halogen-free and flame retardant POE compound | Used for cross-linked and insulating wires and cables of apparatus and instruments, equipments and etc. |

YJZD150 | 150℃ Chemical cross-linkable, low-smoke, halogen-free and flame retardant POE compound | Used for cross-linked and insulating wires and cables of apparatus and instruments, equipments and etc. |

2. Description of Polyolefin:

Chemical cross-linkable POE compound for cables and wires, based on POE resin, is produced and pelletized by special technology with adding special stabilizing agent, modifier, halogen-free flame retardant, cross-linking agent and other special additives. The compound has well thermal deformation resistive and mechanical properties. It suits the cables and wires manufacturers who have rubber production lines, and need not irradiate.

3. Processing of Polyolefin:

The compound could be processed in common rubber extruder, and the recommended processing temperature is 100°C.The user could adjust the temperature properly according to extruder and wires and cables surface status.

Vulcanize processing of the compound could refer to rubber. The details of extrude speed, Vulcanize temperature and time could be adjusted properly according to the equipments and cross-linked status.

4. Storage and transport of Polyolefin:

Packing: 25kg/bag, PE membrane inside bag and craft outside bag.

Avoiding in direct sunlight and weathering.

Storage place should be clean, cool, dry and ventilated.

5. Properties of Polyolefin:

| Item | Unit | YJZD90 | YJZD105 | YJZD125 | |||

| Standard | Typical | Standard | Typical | Standard | Typical | ||

| Density | g/cm3 | -- | 1.46 | -- | 1.45 | -- | 1.45 |

| Hardness | Shore A | -- | 92 | -- | 91 | -- | 89 |

| Tensile Strength | ≥ MPa | 12.5 | 15 | 12.5 | 14.5 | 12.5 | 14.8 |

| Elongation at Break | ≥ % | 150 | 170 | 150 | 165 | 150 | 160 |

| Thermal Aging | |||||||

| Aging Temperature | degree C | 135±2 | 135±2 | 135±2 | 135±2 | 158±2 | 158±2 |

| Aging Time | h | 168 | 168 | 240 | 240 | 168 | 168 |

| Retention of Tensile Strength | ≥ % | 80 | 110 | 80 | 106 | 80 | 110 |

| Retention of Elongation at Break | ≥ % | 80 | 105 | 80 | 98 | 80 | 93 |

| Thermal Prolongation: 20N/cm2 | degree C×min | 200×15 | 200×15 | 200×15 | |||

| Elongation Under Load | ≤ % | 175 | 25 | 175 | 25 | 175 | 25 |

| Permanent Deformation | ≤ % | 15 | 0 | 15 | 0 | 15 | 0 |

| Volume Resistivity, at 20 degree C | ≥Ω*m | 1.0×1011 | 1.1×1012 | 1.0×1011 | 2.0×1012 | 1.0×1011 | 1.2×1012 |

| Dielectric Strength | ≥KV/mm | 20 | 24 | 20 | 24 | 20 | 25 |

| Oxygen Index | ≥ % | 28 | 32 | 28 | 32 | 28 | 33 |

| Impact Brittleness Temperature | degree C | -25 | pass | -25 | pass | -25 | pass |

| Smoke Density Flaming | ≤ | 100 | 66 | 100 | 67 | 100 | 67 |

| Non flaming | ≤ | 200 | 147 | 200 | 146 | 200 | 148 |

| Acidity of gases evolved (pH) | ≥ | 4.3 | 5.3 | 4.3 | 5.4 | 4.3 | 5.3 |

| Conductivity of gases evolved | ≤μs/cm | 2.5 | 1 | 2.5 | 1 | 2.5 | 1 |

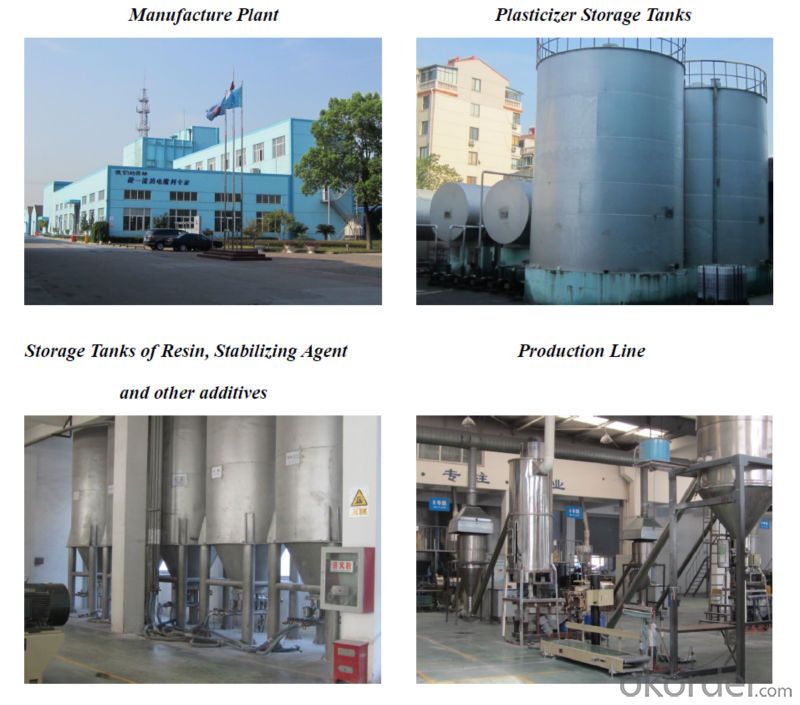

6. Company

- Q:What plastic material is used for plastic hose?

- PP: good corrosion resistance, high strength, high surface hardness, good surface finish, have certain resistance to high temperature hot melt welding, flange connecting thread, sea water, oil and chemical sewage irrigation pipe, concrete floor for indoor heating system for heating pipe

- Q:What two ingredients fit together to solidify like plastic?

- If the viscosity of the epoxy resin is reduced, a curing agent with poor adhesion (e.g., I am a fast curing agent) is adopted. By vacuum and so on, let the glue into the gap, pay attention to the hardness of the curing agent should be higher, so as to effectively measure

- Q:How many kinds of plastic raw materials are there? How to distinguish them?

- Plastic with its superior performance gradually replaced many has been used for decades, hundreds of years of materials and utensils, becoming an indispensable assistant. Plastic and metal in hard wood, light transparent glass ceramic, corrosion resistance, rubber elasticity and toughness in a body. Therefore, in addition to daily necessities, plastic more widely used in aerospace, medical equipment, petroleum chemical industry, machinery manufacturing, defense, construction and other industries.

- Q:What are the common raw materials used in plastic bottles? What are the main features?

- PP bottles are non-toxic, transparent, and have certain heat resistance and impact resistance. They are generally loaded with fruit juice and shampoo. They can be hot filled (very important for fruit juice drinks). They can not be sterilized by pressure cookers, and their transparency is poor.

- Q:What does MFI mean in PC material?

- The measurement of MI is usually based on the standard method of ASTM D1238. It is the principle of the plastic or resin into the metal sleeve of a fixed inner diameter, and heating the plastic or resin after melting, and then give some load on the piston, the piston on the weight of the molten plastic has been squeezed out from a small hole in the charge, and calculate the weight and squeezed out of plastic. This measuring method, because of the same material, the sleeve barrel inner diameter, load, and temperature are fixed, so in addition to test MI, can also be used for the determination of density, viscosity, and melt shear rate, shear stress... etc.

- Q:What are the raw materials of foam plastics and how do they come out?

- The foaming agents for epoxy resins are two types: physical foaming agents and chemical foaming agents. Physical foaming agents are mainly low boiling liquid, such as three chloro methane (F11), three chlorine, three fluorine ethane (F112), two chlorine, two fluorine methane (F12) and so on. By using the curing heat of the epoxy resin, the liquid with low boiling point is evaporated, and the gas is released, and the products are small in density and low in thermal conductivity. But fluorine hydrocarbons have a damaging effect on the atmosphere and are often used to spray foaming processes. According to the experts of China epoxy resin industry association, toluene and so on can be used as auxiliary foaming agent. In addition to foaming, it also acts as a curing reaction, a heat absorber and a diluent.

- Q:What are the raw materials made of modified plastics?

- Broadly speaking, the modification is to change the original performance, such as TPU, flame retardant, anti UV and so on; a narrow sense, the industry will be the new material of TPU polymerization, production is not called modified, and those who buy TPU new material made of flame retardant TPU, called "back modified". The modification process involves adding some resins or additives.

- Q:What kind of material is the raw material of plastic pipes?

- The raw material of plastic pipe is mainly based on the plastic tube type, type, polyethylene plastic pipe (PE) is the raw material of ethylene, polyvinyl chloride (PVC) material is polyvinyl chloride, polypropylene pipe (PB) is the raw material propylene.

- Q:What is the difference between PP raw material and modified PP?

- Sort:(1) according to the characteristics of resin when heating and cooling, classification: 1. Thermosetting plastics, two, thermoplastics(2) according to the use of plastics classification: general plastic, engineering plastics, special plastic raw materialsModified PPThe concept of modified plastic PP, refers to the base of the general plastics and engineering plastics, after filling, blending and enhancement processing method of modification, improve the performance of flame retardant plastic products, strength, impact resistance, toughness.Classification: PP modified plastic products are mainly a variety of flame retardant resins, toughening resin, plastic alloy, functional masterbatch etc..

- Q:That kind of plastic bottle blows well

- PETA hard, tough, high strength, bright surface with transparent and multi colored sheets. The disadvantage is PET high frequency synthesis is difficult, the price is a bit more expensive than PVC, this material is often high-grade products and environmental requirements of the user to replace the PVC PET material generally used to make packaging for food, beverage, pharmaceutical plastic bottles.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Chemical Cross-linkable Low Smoke Zero Haogen Flame Retardant Polyolefin Compound

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 350 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products