CHECK VALVE SWING TYPE DIN/BS/JIS DN40- DN600

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 pc

- Supply Capability:

- 9999 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

Standard or Nonstandard: | Standard | Structure: | Check | Pressure: | Medium Pressure |

Power: | Hydraulic | Material: | Casting | Temperature of Media: | 0℃~80℃ |

Media: | Water | Port Size: | 2" - 10" | Place of Origin: | China (Mainland) |

Model Number: | F7372 | Brand Name: | Eastragon | Application: | General |

Product name: | JIS F7372 5K DN50 - DN250 Cast Iron Straight Type Swing Check Valves | Body material: | Grey Cast Iron | Working pressure: | 5Kgf/cm2 |

Size: | 15-250mm | Standard: | JIS F7372 | Medium: | Fresh Water, Sea Water, Air |

Type: | Straight Swing Check | Certificate: | CCS, ABS, BV |

Packaging & Delivery

Packaging Details: | plastic bag+ box+ carton+ pallet |

Delivery Detail: | 25-40 DAYS |

Technical Date | Material Specification | ||

Nominal Diameter | DN40-DN1000 | Valve Body | Cast Iron or Ductile Iron |

Nominal Pressure | PN10/PN16 | Valve Disc | Cast Iron or Ductile Iron or Stainless Steel |

Operation Temperature | -40°C~225°C | ||

Flange Driling Standard | EN 1902-2 PN10/16 | Seal Material | EPDM OR NBR |

Suface Treatment | Painting | Valve Spring | Stainless Steel |

Application | Portable water, water distribution service & feed lines, sewage disposol, irrigation, fire protection pipe systerm, etc. | ||

Specification

Standard: JIS F7372

Nominal Pressure:5K

Nominal Diameter:DN50-DN250

Suitable Medium: Oil,Water, Acid, vapor

Material Table of Cast Iron Check Valve

Name of Part | Material | |

1 | Body | FC200 |

2 | Bonnet | FC200 |

3 | Disc | BC6 |

4 | Valve Seat | BC6 |

5 | Gasket | NON-asbestos |

Dimensions of F7372 5K check valve

DN | d | L | D | C | NO. | h | t | H |

50 | 50 | 190 | 130 | 105 | 4 | 15 | 16 | 97 |

65 | 65 | 220 | 155 | 130 | 4 | 15 | 18 | 119 |

80 | 80 | 250 | 180 | 145 | 4 | 19 | 18 | 129 |

100 | 100 | 280 | 200 | 165 | 8 | 19 | 20 | 146 |

125 | 125 | 330 | 235 | 200 | 8 | 19 | 20 | 171 |

150 | 150 | 380 | 265 | 230 | 8 | 19 | 22 | 198 |

200 | 200 | 460 | 320 | 280 | 8 | 23 | 24 | 235 |

250 | 250 | 550 | 385 | 345 | 12 | 23 | 26 | 290 |

300 | 300 | 640 | 430 | 390 | 12 | 23 | 28 | 351 |

- Q:What is the difference between globe and check valves?

- 1. check valve is called one-way valve, the role is to prevent fluid flow, can not be adjusted, can not be closed.2., the cut-off valve can be used to regulate flow, can be closed, can be closed.

- Q:How to install industrial check valves? How should they be used?

- 3, when installing check valve, should pay special attention to medium flow direction, should make medium normal flow direction and the direction of the arrow on the body is consistent, otherwise it will cut off the normal flow of media. Valve should be installed at the bottom of the pump suction pipe.

- Q:PPR check valve, butterfly valve, as well as water gauge which quota?

- Is that screw valve set? And what's the quota for the deflector?Chasing the answerBackflow preventer can be fitted with check valves.

- Q:Why is the check valve necessary? Why should it be checked back?

- Check valve, also known as one-way valve, is designed to prevent liquid, gas and other substances backflow design valve.

- Q:Installation of stainless steel tank outlet must be equipped with check valve?

- A stainless steel ball valve can also ah, inner thread

- Q:Is it better to have explicit rules in the relevant specifications? Thank you, ah, ah, urgent.

- Article 8.5 of the code for fire protection design of high-rise civil buildings provides as follows:8.5.3 one of the following circumstances shall be equipped with fire dampers for the ventilation and air conditioning systems:8.5.3.1 pipe through fire compartment.

- Q:Can the swing check valve stand upright?

- Swing check valve, vertical mount, horizontal loading can be.Ordinary lift check valves shall not be erected. Lift check valves with springs can also be mounted.

- Q:What is the function of the check valve in the pipeline?

- Check valve, also known as one-way valve or check valve, refers to rely on the media itself flow and automatically open and close the valve flap, used to prevent the media back flow valve, also known as check valve, Dan Xiangfa, counter flow valve and back pressure valve.Effect:The function is to prevent backflow of medium in the pipeline. Pump water off the bottom valve check valve also belongs to class. The opening and closing parts depend on the flow of the medium and the power is turned on or off by itself. The valve that prevents the backflow of the medium is called a check valve. Check valves belong to the automatic valve, mainly used for one-way flow of media channels, allowing only medium to flow in one direction, to prevent accidents.Check valve installed in the pipeline system, the main role is to prevent media backflow, check valve is a kind of pressure on the media to open and close the automatic valve. The clip type check valve applies to nominal pressure PN1.0MPa~42.0MPa and Class150~25000; nominal diameter DN15~1200mm and NPS1/2~48; work temperature -196~540 degrees of various pipelines, used to prevent medium flow back. By choosing different materials, it can be applied to many mediums such as water, steam, oil, nitric acid, acetic acid, strong oxidizing medium and uric acid.

- Q:My house is public flue, a total of six floor I live five floors, with the side suction hood, hood in the windy outside started as soon as the check valve pops ring from occupancy, have what way?

- Please take the pipe at the hood of the range hood for 15 cm or more, and then blow the wind. Note that the installation of fixed, do not affect the valve sag.

- Q:Can the check valve be used on the steam pipe?

- The check valve can be used on the steam pipe, but only the right material.General steam pressure WCB, temperature and pressure with the then high chromium molybdenum steel. The inside of the valve should be taken into account, depending on the pressure difference.

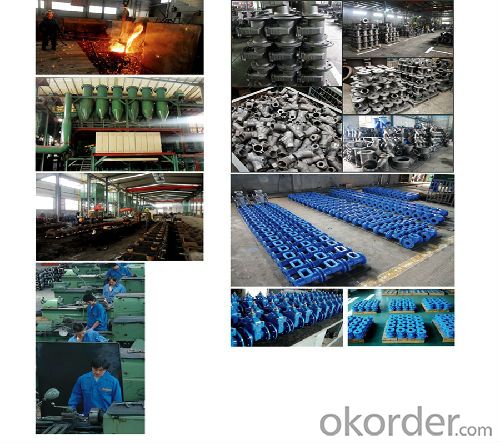

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

CHECK VALVE SWING TYPE DIN/BS/JIS DN40- DN600

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 pc

- Supply Capability:

- 9999 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords