Check Valve of High Quality with API 6A Standard

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 pc

- Supply Capability:

- 100 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Structure of Check Valve Description

This product is designed and manufactured fully in accordance with API Spec 6A wellhead and Christmas tree equipment standards,and can thus be used interchangeably with the products manufactured at home and aboard,which tally with API Spec 6A specifications ,or used to form a complete system.

This is a type of check valves which rely on the pressure of working medium to get meal-to-meal sealing between the core and body(seat). The higher the medium pressure,the better the sealing performance. It is always able to withstand the pipeline pressure within the value cavity.

The body of the valve is forged with alloy steel,which has solid mechanical properties and is able to withstand high pressure in safty and reliability.

The bonnet and the body of the valve are connected with blinding bolts. Sealing washers are used to seal up the bonnet and the interior wall, which reduces the space in between to a minimum (designed as 0),thereby considerably minimizes the erosion of the bolts and the bolt holes,caused by erosive media,and also decreases the load taken by the bolts.

2. Main Features of Check Valve

1) Fitted with a valve-opening indicator

2) Designed with the relief valve

3) Designed with the plane thrust bearing structure

4) Designed with the meal-to-meal sealing structure

5) Fitting with the valve stem sealed by using some special material made lip-shaped packing

6) Made of high wear-resising& corrosion-resising materials, both the valve core and bean are durable

7) Designed and manufactured strictly in accordance with API Spec 6A ,ANSI and NACE MR-0175 standards.

3. Check Valve Images

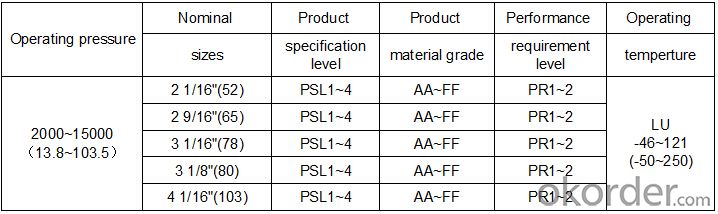

4. Check Valve Specification

5. FAQ of Check Valve

We have organized several common questions for our clients,may help you sincerely:

①How about your company?

One of the leading manufacturers and suppliers specializing Oilfield products in China, mainly offering various of oilfild products consists of our one-stop sales. The integrated sales & service ensures customers with various demands an easier access for purchasing management.

②How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

③How long can we receive the product after purchase?

In the purchase of product within three working days, We will arrange the factory delivery as soon as possible.

- Q:My AC leaks and mechanic says it is shrader valve. Is it expensive?

- It is like the valve in a tire stem. No, it is dirt cheap - like four bucks if that. Why didn't mechanic just replace it? You can replace this yourself. Just go to a parts counter and ask them to look up your car and they will find a valve. Then ask them for the tool. You can probably get both for under $15. But you will have to wait until all the refrigerant leaks out of it hasn't already. You don't want to take out a valve from a pressurized system. You can also recharge the system yourself too. They now sell the hose that attaches to the can with a built in valve. It isn't difficult if you can follow directions.

- Q:How come my boiler supply valve isnt letting water into my boiler, i have a cold water supply hooked up to it with the valve on i have tested the copper pipe goin into it and water flows into it, but when It reaches the valve it stops. I understand that it my have a backflow preventer in it and I am wondering if that could be malfunctioning. The hole you see on the front is where my expansion tank screws in. Also where could I get a new Valve. Thanks.http://img149.imageshack.us/i/boilerfillvalve.jpg/

- I work on antique steam boilers and engines for a hobby and if your supply valve isn't letting feedwater into the boiler, I'm going to tell you right now that you potentially have a VERY dangerous situation on your hands. Until you get this issue resolved, I would recommend that you not steam this boiler up under any circumstances, unless you have a backup feedwater delivery system that is working correctly. Many people don't know this, but a low water condition in a boiler under steam is essentially a ticking time bomb and can result in a fatal explosion. As to what may be causing it, I would say it's possibly one of two things: 1.) The check valve has been installed backwards and the flow of water is basically pushing it shut. 2.) The check valve is installed correctly, but is frozen shut due to corrosion and scale. Either way, I would have a certified boiler inspector come out and take a look at it; he can probably tell you more than I can.

- Q:when heater heats water there is a small leak thru the releif valve. need answrers to possible reasons for malfuntion. leak is not continous.

- OKAY...the 30 psi is bogus....I've never heard of that! The pressure coming into your house and the water heater is typically 70psi to 100psi....the relief valve is set to pop off at 175 psi....if the pressure in your water heater reaches 175 then the valve will pop....when this happens you need a new relief valve....you may want to figure out why this happened also......your heater may be set too high... try turning it down a little......but first check the incoming water pressure to your home....do this by buying a water pressure gage and screwing it on to an outside hose bibb and turning the hose bibb on......if the pressure is over 80 psi (which is what most plumbing code calls for) then you probably want to install a pressure regulator in the yard to lower the pressure......Example.....if you have 120psi coming into the water heater, and when water heats it expands and builds pressure then you could reach 175 psi and your relief valve will pop off.......good luck!!

- Q:Does anybody know what the valve lash specs are on a 1986 chevy sprint 1.0L carbureted?

- if you cant see clearly, just right click it and choose save as so you can enlarge it. this will be important. now... Rear of vehicle side = Intake valves Font of vehicle = exhaust valves Rotate crankshaft clockwise and align the timing notch on the pu;;ey to 0 on the timing tab. Remove the distributor cap and ensure the rotor is at 3 oclock This position indicates the is at compression stroke. TDC #1 cylinder. Using feeler gauge between rocker and valve syem, check intake and exhaust valve clearance on cylinder #1. After adjustment tighten the locknut to 11 to 13 ft pounds torque.

- Q:My 91 GMC Van has an Idle Control Valve that is unplugged, but the van still runs great. Will the valve being unplugged, result in harm to my vehicle?

- Won't hurt a thing.

- Q:If someone is not born with heart valve disease... can a teenager or a 12 year old develop heart valve disease?

- If a teen has heart valve disease, is most likely something they where born with, but it can go undiagnosed till the are teens. I was born with aortic stenosis, aortic regurgitation, bicuspid aortic valve(all are valve disease) and i also have an enlarged aorta. Im 16 years old. I was born with the bicuspid aortic valve and aortic stenosis, and that caused me to develop aortic regurgitation when i was 10, and an enlarged aorta at 14. In some cases a teen can develop it with out being born with it, its uncommon but it can happen.

- Q:adjusting the overhead valves on briggs and stranton 14.5 engine

- Roll the engine over until the valve is completely closed. You can do this by watching the valve close, then turn the engine over until it just strats to raise. Now turn it back half way. Now losen the rocker arm and place a .003mm to .005mm filler gage between the push rod and the rocker. Tighten the rocker arm nut down so that the filler gage pulls out with a light drag. Do this with the other rocker and you are good to go.

- Q:Is it hereditary? My dad had a bicuspid valve and we got told it was hereditary but some doctors say it's not, my parents wanted to get me tested in case i had it so we would know in advance but the doctors here refuse to do it (I live in England if that makes a difference) my dad said he would pay to go private if it's hereditary. I know someone who had a bicuspid valve and 3 out of her 4 children inherited it, i know it's pretty harmless until i reach an older age but my parents and i would like to know now, i'm 13 by the way.=]

- Yes, some studies have found Bicuspid aortic valve to be hereditary. Some studies show that the incidence of bicuspid aortic valve can be as high as 5% in families affected with the valve issues. In the UK there is no routine screening for people with relatives who have BAV. If you develop any symptoms or problems then of course see your GP again.

- Q:I have an 98 Mitsubishi Eclipse rs and its a little jerky while driving and i think it might be the PCV valve but I don't know where it is located.. where is it? and would this cause the check engine light to come on?

- Your okorder okorder , which covers all Eclipse/Talon models.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Check Valve of High Quality with API 6A Standard

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 pc

- Supply Capability:

- 100 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords