CHECK VALVE LIFT TYPE DUCTILE IRON DIN DN15- DN300

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 pc

- Supply Capability:

- 9999 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

Standard or Nonstandard: | Standard | Structure: | Check | Pressure: | Medium Pressure, 1.0Mpa, 1.6Mpa,2.5Mpa,4.0mpa |

Power: | Manual | Material: | Casting, cast steel,WCB, stainless steel, ect. | Temperature of Media: | Normal Temperature |

Media: | Water | Port Size: | DN15-DN300 | Place of Origin: | Tianjin, China (Mainland) |

Model Number: | CMAX | Brand Name: | CMAX | Application: | General |

Name: | iron water lift check valve | Connection: | Flange | Temperature: | ≤425℃ |

Standard: | GB,BS,ANSI,JIS,DIN,etc | OEM: | Acceptable | Color: | Customized |

Certification: | ISO,CE | Warranty: | 12 month |

Packaging & Delivery

Packaging Details: | standars export wooden for Alibaba Bell DN100 adjustable cast iron water lift check valve |

Delivery Detail: | 20 days |

Technical Date | Material Specification | ||

Nominal Diameter | DN40-DN1000 | Valve Body | Cast Iron or Ductile Iron |

Nominal Pressure | PN10/PN16 | Valve Disc | Cast Iron or Ductile Iron or Stainless Steel |

Operation Temperature | -40°C~225°C | ||

Flange Driling Standard | EN 1902-2 PN10/16 | Seal Material | EPDM OR NBR |

Suface Treatment | Painting | Valve Spring | Stainless Steel |

Application | Portable water, water distribution service & feed lines, sewage disposol, irrigation, fire protection pipe systerm, etc. | ||

- Q:Does the check valve damage affect the flow rate?

- Ball check valve will not affect the flow, such as the clip type check valve once damaged, it will affect the flow.

- Q:The role of the clip lift check valve

- Among them, the internal check valve, butterfly check valve belongs to this type of valve, which includes swing check valve and lift check valve. The swing check valve has a hinge mechanism and a gate like valve free against the inclined seat surface. In order to ensure that the valve can reach the appropriate position of the seat surface at any time, the disc is designed in the hinge mechanism so that the disc has enough swing space to make the disc real and comprehensive contact with the valve seat. The disc can be made of either metal or leather, rubber, or synthetic coverage, depending on performance requirements. The swing check valve is almost completely open and the fluid pressure is almost unimpeded, so the pressure drop through the valve is relatively small

- Q:The working principle and structure description of the mute check valve

- When the valve is in use, the medium flows according to the direction of the arrow.1, when the medium according to the provisions of the direction of flow, the valve by the media force, is open; the medium back, due to weight and disc valve by the medium reverse force, so that the sealing surface of the valve flap and valve seat sealing and closed, to prevent the media counter to.2, the body and valve sealing surface using stainless steel surfacing.3, the length of the valve according to the provisions of GB12221-1989, flange connection size according to the provisions of JB/T79-1994.

- Q:Check valve H15B-16 DN25 is that product?

- Screw swing multi valve check - nominal pressure 1.6Mpa, product caliber 25mmOur company has production!

- Q:Check valve symbols?

- Check valve refers to rely on the flow of the media itself and automatically open and close the valve flap, used to prevent media backflow valve, also known as check valve, one-way valve, counter flow valve, and back pressure valve. The check valve belongs to an automatic valve, whose main function is to prevent the backflow of medium, prevent the reverse of pump and drive motor, and release the container medium.The opening and closing parts depend on the flow of the medium and the power is turned on or off by itself.

- Q:What is the HC41X-16Q model of the optical valve? What is its main function?

- the medium back, due to weight and disc valve by the medium reverse force, so that the sealing surface of the valve flap and valve seat sealing and closed, to prevent the media counter to.1, fluid flow is smooth, local head loss is small;2 、 with guiding device, closed flexible, linear sealing, good return effect, can effectively reduce noise;3, small size, light weight, easy installation and maintenance.

- Q:Does the check valve of the flue of the range hood work?

- Lampblack machine flue check valve is generally installed in the hood outlet check valve, the valve has two blades, a reset spring, exhaust hood leaf was blown open, lampblack machine stop when the blade is spring pressed into the closed state, now is basically take lampblack machine the check valve check valve, but the general tightness is not very good, open the hood can be seen around the gap. According to everyone's reaction and market similar products sold well, smoke hood comes with soot hood flue check valve basically does not work.The picture of the check valve of the flue of the range hood is as follows:

- Q:How much is the check valve for the concrete pump?

- 31 concrete pump price ranging from 15W to 60W, different configurations have different prices, which one do you want?

- Q:What are the brands of check valves?

- Check valve refers to rely on the flow of the media itself and automatically open and close the valve flap, used to prevent media backflow valve, also known as check valve, one-way valve, counter flow valve, and back pressure valve.

- Q:My house is public flue, a total of six floor I live five floors, with the side suction hood, hood in the windy outside started as soon as the check valve pops ring from occupancy, have what way?

- Do you think the situation in the wind ` a valve installed in the opposite direction of the flue you can, you should pay attention to when installing wind don't understand the whole, an anti air valve system, like on the wall in the general store has large lampblack machine. Or you in the hood where to buy, you can go to a can go, I also bought the lampblack machine, where he will give you, or call at the time according to the hood people to give you what you can handle.

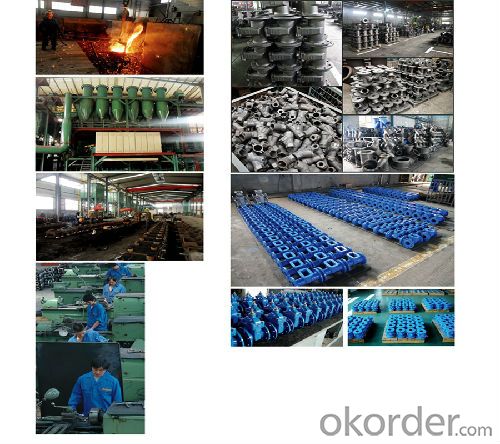

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

CHECK VALVE LIFT TYPE DUCTILE IRON DIN DN15- DN300

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 pc

- Supply Capability:

- 9999 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords