Chameleon Color Aluminium Composite Panel

- Loading Port:

- Guangzhou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Quick Details:

Panel Thickness:2mm-4mm

Coating: PE and Kynar 500 PVDF Coating

Width:1220mm, 1250mm, 1500mm. 1550mm, 1570mm etc

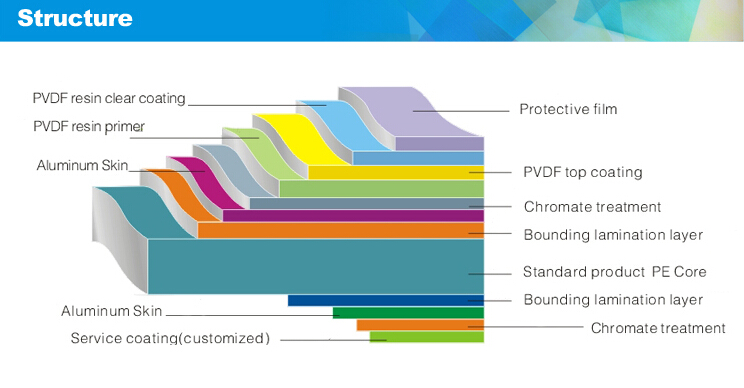

2. Basic structure of Aluminium composite panel

1) Protective film

2) Coating-basic level PE Or PVDF coating

3) Ground coating=premier coating

4) Aluminum Alloy sheet 1100 H14

5) Macromolecule adhesive made by SK Korea, more than 90 degrees.

6) LDPE(recycled-plastic) no-toxic Or fire-rated material

7) Macromolecule adhesive made by SK Korea, more than 90 degrees.

8) Aluminum Alloy sheet 1100 H14

9) Ground coating premier coating

- Q:Today, just started to do LED electronic light box, with aluminum-plastic plate openings, plug lights, even lights, street controller, that is done well. Ready to power, check with multimeter, find! shock! The Aluminum-plastic plate side is aluminum foil, conductive! The The 1 how to do? The The LED electronic light box, not using aluminum plate to do it? The

- With plywood, fibreboard also line (also useful iron plate, aluminum plate). But no matter what board, wires, devices, should not touch the board, should be insulated, otherwise, the rain board will be wet, but also conductive.

- Q:Analysis of why the surface of aluminum-plastic plate deformation, from the drums

- Casually in which city in the circle, are not difficult to find some aluminum-plastic plate surface deformation, from the drums of those big unpleasant works. Small facade renovation works on this phenomenon, large high-rise buildings also have this phenomenon. In the construction, the emergence of such a quality problem, we have considered the quality of the plate itself; later, after we focus on the analysis found that the main problem lies in the paste sheet of aluminum-plastic plate, followed by aluminum The quality of the board itself. Dealers often provide us with aluminum-plastic plate construction process, the recommended use of grass-roots materials are mainly high-density board, woodworking board, etc. In fact, such materials used in the outdoor, its life is Very fragile, after the wind, sun, rain, will inevitably produce deformation. Since the grass-roots materials are deformed, then as the surface of the aluminum-plastic plate that is not deformed? Can be seen, the ideal outdoor base material should be After the rust treatment of angle steel, square steel pipe to form a skeleton is better.If the conditions permit, then use aluminum as a skeleton is more ideal. This type of metal material produced skeleton, the cost is not higher than the wood keel, high density Many, can really guarantee the quality of the project.

- Q:Not clear, and we help me say the difference between them, advantages and disadvantages

- Aluminum slab plate, aluminum-plastic panels have integrated ceiling, but in general beforehand, the two are essentially different things a big thing aluminum plastic. The price is also a big difference

- Q:That is to say if you buy 10 standard size 1220 * 2440 aluminum panels about 3 square meters need to buy the number of universal glue, the proportion of their construction between the number?

- With the universal glue factory configuration of the plastic scraping, the general standard with the amount of glue for 1KG glue scraping 4 square area, so coated with plastic layer is more uniform, the normal time to fit the construction of the drum situation is difficult to occur. This is a lot of glue manufacturers have instructions on the use of packaging, you can pay attention to the next.

- Q:What are the folds of aluminum

- Aluminum-plastic composite board slot can generally open V-groove, U-slot, etc., several typical slotted as shown in Figure 1. Aluminum-plastic composite panel plate in the cutting board to take into account the size of the fold , Generally add about 25mm on each side. Cut the composite board needs four sides of the planing slot, that is cut to a certain width of the inner layer of aluminum and plastic layer, slot depth must be strictly controlled in the front aluminum plate at least 0.3mm thick plastic core To ensure that the aluminum-plastic composite panels have sufficient toughness to prevent the fold at the aluminum skin fracture, and then folded into a 90 ° angle, so the board surface weight and curtain wall at any time will be positive and negative wind load pressure by the four sides 0.5mm aluminum plate to bear, therefore, slotting is the aluminum-plastic composite panel panel of the weakest link, but also under the wind load under the first destruction of the site

- Q:Chengdu Deyang made of external walls of aluminum-plastic package material how much money a square

- Our common offer is 350 yuan / square meter or more, the highest is 800 yuan / square meter. Generally in the 450 yuan / square meter more reasonable. Can use real material.

- Q:30-storey residential building roof concrete flower frame decorated with aluminum-plastic plate, please apply to apply lightning belt can not do? Using aluminum-plastic plate grounding

- From the lightning protection technology, aluminum-plastic plate material in the presence of metal aluminum alloy,

- Q:Astella aluminum plate 3 plywood price how much ah?

- Such as 0.20 mm, 0.18 mm, 0.15 mm, 0.12 mm, 0.08 mm, 0.06 mm, etc., the price of each thickness is different, while the surface of aluminum 0.20 mm, aluminum 95; Price can be seen is not the same, therefore, generally asked, but can give a range of 80-180 yuan, should be the price.

- Q:Aluminum-plastic plate pillars, slot depth and the tip of what is the relationship

- No direct relationship - depth is artificially adjustable! The style of the tip is related to the requirements of the slot - there are V, U and other shapes

- Q:I would like to ask the next aluminum plate, aluminum veneer and aluminum composite panels are three characteristics

- Aluminum-plastic composite board is a chemically treated coated aluminum sheet for the surface material, with polyethylene plastic as the core material, in the special aluminum-plastic plate production equipment from the processing of composite materials.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Chameleon Color Aluminium Composite Panel

- Loading Port:

- Guangzhou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords