Ceramic Fiber Yarn Low Thermal Conductivity

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m³

- Supply Capability:

- 68 m³/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Ceramic Fiber Yarn Low Thermal Conductivity

Description for Ceramic Fiber Yarn

Ceramic fiber Yarn is made from high quality clay, high

purity alumina and silica oxides by spun or blown process.

Ceramic fiber yarn has a range of products:ordinary type,standard form,high-purity type, high-alumina type and containing zirconium type.Different types of products used different materials. performance of ceramic fiber yarn also has difference,and they are suitable for different workong temperatures.

Ceramic fiber yarn can be used after optional cutting .When ceramic fiber yarn storage should be paid attention to moistureproof.The high-alumina type and containing zirconium type products can be directly used as furnace lining .And using high-temperature refractory adhesive when stick.

Features for Ceramic Fiber Yarn

◆Low thermal conductivity

◆High tensile strength

◆Resilient to thermal shock

◆Corrosion resistance

Advandage for Ceramic Fiber Yarn

◆High-purity type

◆High-temperature refractory

◆Al Content (%): 32-55

◆Type: 1260℃ STD/HP, 1350℃ HA, 1430℃ HZ

◆Density: 64-160kg/m3

◆Size: 12.5×610×14400mm, 25×610×7200mm, 50×610×3600mm

Images for Ceramic Fiber Yarn

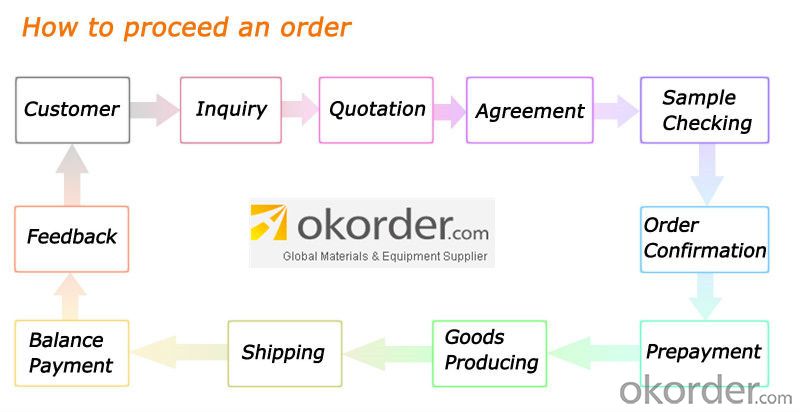

◆Product Process

◆Packaging

FAQ

Can we accept OEM for Ceramic Fiber Yarn?

YES! We can according your demand to produce.

Can we accept the detective of the third-party verification company ?

YES! We can accept the detective from any third-party verification company including the SGS, BV and so on.

If you have any enquiry,please don't hesitate to contact us,okorder will provide our best products and services for you!!

- Q:I don't want to get on the roof if I don't have to.

- ya mal died in real life because she couldn't tell the difference between dream and reality when cobb found her safe in the house (u know the doll house and spun the dradle) it mixed up her perception of reality and dream she died when she jumped out the window in reality To answer everything else, They weren't in a dream,they were in limbo,which is empty dream space where u go if u die while in inception.they escaped limbo by killing themselves to wake up and believing it was reality (I know confusing right?) She is still in cobbs dreams because he feels guilty over her death and she basically has made a home in his concioncesthats why she keeps screwing up the missions for cobb his guilt is not allowing him to think rationally as for the lurid dreamthat

- Q:is it suitable to person who suffers arthritis , i mean joint pains in nights , muscle pain in legs, fatigue toowho she also difficult to consume normal meal slots whether bread or vegetable minced form onlyit seems ulcers (mouth) she doesn't posses any other disease than low BP, less calories, can't eat any hot spicy foodMETAMUCIL a Canadian High fibre flavoured drink.can't keep more than 3 minutes once mixed or pour water into the above powderinstructions say not suitable to drink if the drink turn as set jelly.give me feedback whoever known well.doctors from Canada preferred others thanks in advance.

- So The Carpet Will Not Be Loose, It Needs To Be Tight So They Want Be Wrinkles, Bumps, etc.

- Q:My husband doesn't get enough fiber in his diet and he refuses to do anything about itI have an idea to grind up fiber supplements and put them in his food.How well will this work? Will he notice them?

- Yeah, making temporary bridges is one of the functions of the Army Corps of Engineers.

- Q:Me and my friend are starting a yarn club our school and we need help coming up with a good name to draw people inWe will be doing several projects dealing with yarn, including the products listed in the questionAny Ideas? Thanks for your feedback

- Fiber helps you lose weight by keeping you regular (washroom)The best way to lose weight and keep it off is to eat small portions 5-7 times a dayThis way, your metabolism is always working and burning caloriesYou should never starve yourselfIf you do, you will lose weight of course, but as soon as you start eating normally you will put it back on, plus moreThis is because your metabolism has slowed down due to lack of food, and once you start eating normally again, it wont be able to keep up and you will gain a lot of weightSo what i recommend you do is, nutrition wise, get your daily dose of fiber, through foods or a supplementEat small meals throughout the day, stick to whole grains and lean meats, such as chicken, turkey, and for fish, salmonAlso, you can work outCardio is best for weight loss, but weight lifting also helps burn calories Hoped this helpsAlex.

- Q:How much yarn do I need to make a jacket?

- I'll say somewhere about 400 hp unless you spin it to the moonWith heads that big on a 327 it'll be a complete dog on the street as previously mentioned, and that comp ratio would have me concerned on pump gas, you may want to get the cranking pressure so you don't get detonationI would seriously recommend you to sell off the 327 and at least go with a 350 or better yet a 383 with those heads and camyou will be much happier with the torque and itll still spin up goodremember there's no replacement for displacement!

- Q:If I wanted to Spray Paint or Dip an Object in order to Color it, what would that Dip be? Must be ORGANIC!?

- Here in NoCalifwe have our garbage recycling bins that we put out every other week( one week it is garden waste next week if is recycling)In it I put newspapers, any shredded recycled paper, any waste paper, tin cans, bottles and plastic containersAll my aluminum cans and plastic bottles and such I take to the recycling centers when I have accumulated enough to make it worth the effert to go there, and get money back for thoseI think is is running about 1.75 to 1.95 a LB right nowWe do have to pay a disposal fee at the grocery store when we buy beverage cans or water or soda plastic bottles, so no reason not to get our money back, rightSo yes I do my bit to recycle

- Q:Couple questions, How much fiber are you suppose to have a day? What is fiber good for? What foods are high in fiber either fruits and veggies or any man made foods?If you have any answers that would be really helpful!!!

- 20 to 30 grams of fiber is recommended by the ADAFlax seed wheat bran whole wheat flour, whole wheat pasta Most fruits and vegetables Nuts Don't forget to drink plenty of water as well because without it causes digestion problems.i.econstipation, etc.

- Q:i saw it somewere before, i believe it orginates in the US by a couple who tried to find a new way to decorate the wall, this thing is made of paper, there r various shape of this thing, many size, small to big ,basically, this thing is made of paper,the paper was cut into shapes, for ex, flower, star, blah blah.and this things r sold in set.any1 know this thing name?Thanks for any suggestion.TOm

- I'm pretty sure you're talking about WalliesYou can get them at Hobby Lobbys, Menards, Lowe's Home Depot, Some big Chain Fabric Stores, and Probably other big craft stores, maybe K-mart (I can't remember where I got the Blue's Clue's set )At Hobby Lobby, they're located near the fabric and yarn section.

- Q:So, the past couple days I have been going vegetable crazy and eating nearly an unnatural amount: with each meal, snacks in between meal, etcas you could imagine, this has left me extremely gassy and bloatedI was wondering if you knew of any home remedies that could help eliminate it?Also, is eating a lot of veggies like this unhealthy?

- Alpaca because it is so soft and warm but isn't scratchy like mohair.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Ceramic Fiber Yarn Low Thermal Conductivity

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m³

- Supply Capability:

- 68 m³/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords