Ceramic Fiber Spun Bulk

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 kg

- Supply Capability:

- 10000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details for Ceramic Fiber Spun Bulk

| Place of Origin: | China (Mainland) | Brand Name: | Model Number: | STD | |

| Application: | Expansion joint packing | Grade: | ST (Standard) | Dimensions: | 18kg/bag |

| Working Temperature: | 2300F | Fiber Diameter: | 3-4.5um | Color: | Pure White |

| Fiber diameter(um)Blown: | 2--3 | Fiber diameter(um)Spun: | 3-4.5 | AL2O3(%): | 45--46 |

Packaging & Delivery

| Packaging Details: | Woven bags,carton or according to customer's requirement |

| Delivery Detail: | 10days |

ceramic fiber spun bulk

FAQ 1

1.What is your MOQ?

A :MOQ may vary by customer's special requirement; we try our best to meet your business requirement.

2.Can you provide sample?

A: Yes, we can offer sample , and some samples are free

3. Can you delivery by express?

A: Yes, we can delivery by any express

4.Can you accept OEM ?

A: YES! We can according your demand to produce.

5. How to solve the quality problems?

A:If the products are not conform to customer samples or have quality problems, our company will be responsible.

6. what‘s your regular practice concerning terms of payment?

A: Payment terms :T/T 30%-50% deposit after order confirm ,the balance after goods ready before shipping or L/C, or Western Union for small amount. Or PAYPAL.

7. How long does it usually take you to make delivery?

A: Lead time: Normally about 10 days after deposit received

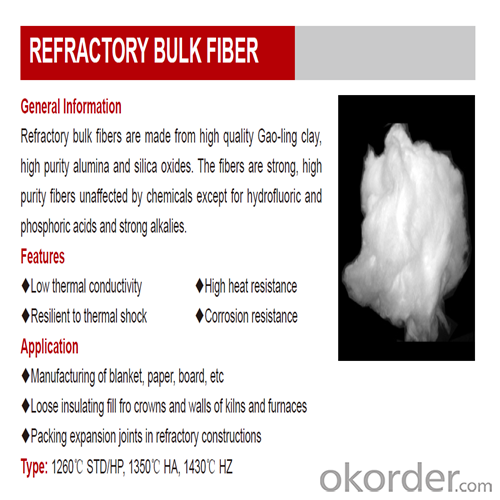

Product Description

The ceramic fiber are manufactured from high purity raw material alumina powder ,silica sand for the high temperature grades and zircon sand is also used. The ceramic mixture is heated in an high temperature electric furnace and the stream of molten material is drawn into fibers by either spinning or blowing .It is produced by advanced “blown” and “spun” processes .Ceramic fiber bulk shows a high temperature stability ,low weight and heat capacity and an outstanding sound absorption is complemented by their resistance to oxidation and reduction

Excellent thermal and chemical stability

Low thermal conductivity and heat storage

Excellent thermal shock resistance and sound –absorption capability

No bonding agent and corrosive substance

Asbestos free

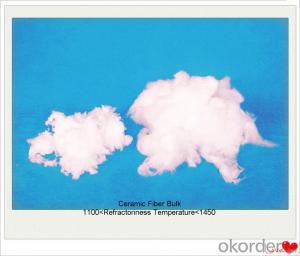

Technical data for Ceramic fiber Bulk

Type | COM | STD | HP | HA | HZ |

Classification temp(ºC) | 1100 (2012℉) | 1260 (2300℉) | 1260 (2300℉) | 1360 (2480℉) | 1430 (2606℉) |

Work temp(ºC) | <1000< span=""> (1832℉) | 1050 (1922℉) | 1100 (2012℉) | 1200 (2192℉) | 1350 (2462℉) |

Color | Pure White | Pure White | Pure White | Pure White | Pure White |

Fiber diameter(um)Blown | 2--3 | 2--3 | 2--3 | 2--3 | 2--3 |

Fiber diameter(um)Spun | 3—4.5 | 3—4.5 | 3—4.5 | 3—4.0 | 3—4.0 |

AL2O3(%) | 44 | 45--46 | 47--49 | 52--55 | 39--40 |

AL2O3+SIO2(%) | 96 | 97 | 99 | 99 | ------- |

ZrO2(%) | -------- | -------- | -------- | -------- | 15--17 |

Fe2O3(%) | <1.2< span=""> | <1.0< span=""> | 0.2 | 0.2 | 0.2 |

Na2O+K2O(%) | ≤0.5 | ≤0.5 | 0.2 | 0.2 | 0.2 |

FAQ 2:

1. Which products do you have?

We have all kinds of refractory brick, castable, mortar, cement, ceramic fiber products, etc.

Or you could browse our products to choose what you need.

2. Can you give me a general idea of the specification and technical data of your products?

Yes, catalog is on your request.

3. Can you give me a brief introduction of the application of your products?

We are mainly specializing in the refractory materials in iron and steel, cement, glass, ceramics, petrochemical, electric power Industry, etc.

4. If I need your offer, what information do you need?

In order to choose suitable products, it will be appreciated to provide us the information, such us specification, technical data, order quantity, products application etc.

If any question, please contact us freely.

- Q:Is aluminum silicate fiber poisonous?

- Ceramic fiber loose cotton is a kind of fluid which can melt high purity clay clinker, alumina powder, silica powder, chrome sand and so on in the industrial electric furnace.

- Q:Aluminum silicate ceramic fiber cotton smoke will cause pneumoconiosis?

- 1, general masks, gauze, masks, etc., can not be used as dust masks.2, mask must pass GB 2626-2006 standard certification.3, it is recommended to choose N100 class dust masks.4, individual suggestions according to choose different shapes masks.5, it is recommended to change the filter gauze mask. Material recommended for silicone material.Through the above way, it can effectively prevent pneumoconiosis.

- Q:Glass fiber cotton, aluminum silicate cotton, rock wool, what's the difference between these three?

- Rock wool: is a kind of insulation materials, widely used in exterior wall insulation, because rock wool dust carcinogenicity, the state has banned the use of industry.

- Q:The difference between the ceramic fiber blanket and rock cotton blanket

- Refractory ceramic fiber material is a lightweight and efficient thermal insulation material. It has the following advantages over traditional heat insulation materials:Ceramic fiber as lining, low volume density: ceramic fiber lining than light heat insulation brick lining light more than 75%, lighter than light castable lining light 90% to 95%. If using fiber lining, it can greatly reduce the steel structure load and prolong the service life of the furnace.

- Q:Is the ceramic fiber cloth poisonous?

- Aluminum silicate fiber textiles can replace asbestos textiles, widely used in metallurgy, chemical industry, ceramics. Glass, refractories, shipbuilding, aerospace, automotive, machinery, electronics, building materials, light industry and other industrial sectors of the fire-resistant, heat insulation, fire prevention, friction, sealing, silencing, labor protection, high temperature filtering etc..Landlord, it seems that this material is non-toxic, rest assured that the use of good.

- Q:What is the good heat insulation effect of glass fiber and aluminum silicate fiber, what are their respective advantages and disadvantages?

- Advantages and disadvantages of aluminum silicate fiber: high temperature insulation, heat preservation, fire resistance, noise reduction, insulation, light weight. Disadvantages: compressive resistance, bending force is relatively poor, easy to produce dust, waterproof performance is not very good.

- Q:Ceramic fiber material fire shutter door how many square?

- If the above two kinds of roller blinds, really true to do, the former per square meter at least 500 yuan, and the latter at least 400 yuan per square meter. Otherwise, there must be a problem.

- Q:What is the density of ceramic fiber modules? The best insulation effect

- Ceramic fiber module density in 200-220, the first production of ceramic fiber module is generally made of ceramic fiber blown blanket, fiber blown blanket fine short, ceramic fiber module is made out of the expansion is relatively stable, but in recent years because of the cost of production, the majority of ceramic fiber module are thrown silk do relatively, the tensile force is big, according to your own combustion atmosphere of furnace temperature and heating module and intracranial, select the density and thickness of the ceramic fiber module. Just make the insulation layer, then recommend 200kg/ cubic meters. Ring fire-resistant insulation materials company has a specific index and design analysis.

- Q:Aluminum silicate needle carpet and ceramic fiber insulation performance of the good

- Aluminum silicate needle carpet should be aluminum silicate needled blanket, with the continuous production, by acupuncture fiber uniformity, high tensile strength, does not contain any additives. Ceramic fiber, also known as aluminum silicate fiber, is only a different name.

- Q:What is the diameter of the ceramic fiber? How to mix?

- Fiber length: fiber rejection is longer, the rejection of silk fiber is generally 150-250mm, spinneret fiber is generally 100-200mm;

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Ceramic Fiber Spun Bulk

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 kg

- Supply Capability:

- 10000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords