Ceramic Fiber Refractory Insulation 25mm Thickness Blanket, 96 Bulk Density

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 200 kg

- Supply Capability:

- 5000000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

General Information of Ceramic Fiber Blanket

l Ceramic fiber blanket is a needled blanket that is made from high purity spun ceramic fiber, suitable for high temperature insulation up to 2300°F.

l CMAX ceramic fiber blanket is made from high quality Kao-Ling clay, high purity alumina and silica oxides by spun or blown process.

l Ceramic fiber blanket is asbestos free. Double-side needling provides ceramic fiber blanket with great tensile or handing strength for easy installation.

Product Sizes and Variants of Ceramic Fiber Blanket

Width: ≤1220mm

Thickness: 6-60mm

Density: 4, 6, 8 lbs./cu. ft. (64, 96, 128 kg/m3)

(Non-standard sizes are available upon request)

Also available with aluminum foil back

Customer Application Notes

Product Handling: Require protective gloves, cloth, mask and dust control.

Application of Ceramic Fiber Blanket

Petrochemical process heater refractory fiber lining

Heat treating furnace or Intermittent (shuttle) kiln hot face lining

General furnace backup insulation

Heat seals for kiln car or furnace door

Electrical insulator

Image of Ceramic Fiber Blanket

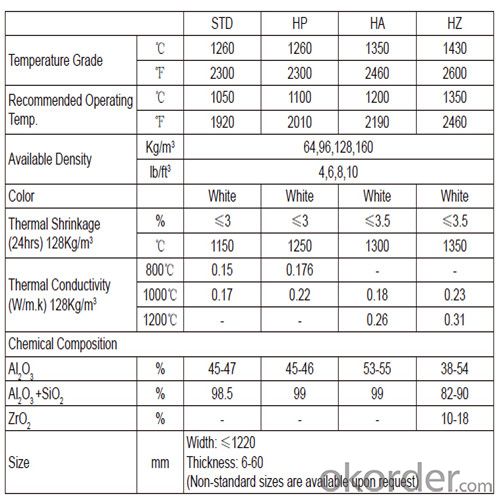

Technical Data of Ceramic Fiber Blanket

Who We Are

OKorder is offering high quality Ceramic Fiber Blanket at great prices with worldwide shipping. Our supplier is a world-class manufacturer of ceramic fiber products, with our products utilized the world over. OKorder annually supplies a full range of products to European, North American and Asian markets. We provide quotations within 24 hours of receiving an inquiry and guarantee competitive prices.

Why Choose Us

We are a government owned company with ISO certificate.

We are listed in Global Fortune 500 with D & B report.

We have more than 11 refractory production facilities and bases across China. We have a wide products range, such as ceramic fiber products (ceramic fiber blanket, module, board, paper, bulk), ceramic fiber textile (ceramic fiber rope, cloth, tape, yarn) etc, refractory brick (fireclay brick, high alumina brick, silica brick, magnesia brick etc), monolithic refractory materials, insulating fire brick, calcium silicate board, mica sheet, steel fiber. You can find various products here, and we can combine the light weight ceramic fiber products with the heavy weight refractory brick in one container delivery, then save the sea freight for you.

We have strict materials selecting system and quality control system. We have the ability to take responsibility for your orders and product quality.

FAQ

Q1: Why buy Materials & Equipment from OKorder.com?

A1: All products offered by OKorder.com are carefully selected from China's most reliable manufacturing enterprises. Through its ISO certifications, OKorder.com adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q3: What other products does OKorder offer?

A3: We offer a full range of refractory bricks, monolithic material, ceramic fiber products, and more.

Q4: If I need your offer, what information do you need?

A4: In order to choose suitable products, it will be appreciated to provide us the information, such us specification, technical data, order quantity, products application etc.

If any question, please contact us freely.

- Q:I have a plan of eating strictly beans and nothing else because of my weight loss plan, because bean is cheap and has 0 fat, 0 cholesterol, extremely low sodium and sugar, high fiber and protein, some calcium and iron, high carb but that is needed for energy, so I plan on eating only beans all day long, drink only water and work out at the gym many hours and take a multivitamin a dayBut it didn't work out because I got sick and thre up beans so are there any other food out there that packed a punch and cheap and won't get me sick?

- I have seen starter kit on radar in some surplus stores It is not link huge radius or something It can be use for motion detection on home premise or something like that.

- Q:Bergamot clutched at knitted fibres of forrest,sausage fingers -a child's play dough creation birthed this masterpiece,reddened tips stroked natures ply's,woven with easea pleasantFrankenstein's work or a careless skillstirred from within.

- If you mess up,a pot holder may turn out to be toy for a catBe careful not to knit monstrous creations.This reminded me of my aunt who raised me.She loved knitting, I still have some of her blankets.Thanks for sharingNice heart warming poembye

- Q:I'm working on finishing my atticMy house was built in 1932 and is located in Michigan.The attic space is approximately 24'x24'The rafters are 2quot;x6quot;, 16quot; OC, 13'6quot; in length from bottom to peak, at an angle of 33 degrees.My question is: can I install 7/16quot; osb sheathing on the bottom of the rafters to use for a ceiling? Will the dead load be too great?There would be about 9+ sheets of 4'x8' osb on each side, and the rafters already show normal slight sag, from the weight the roof, and live loads each winter.I'm interested in using the osb, because I have thin tongue-and-groove pine which is flimsy on it's ownI believe the 7/16quot; osb 4'x8' sheathing would provide good backing.

- natural fibers have pours and the synthetic are made of plastic?

- Q:Typically, there are a dozen or more cats that come and go through the yardWe feed them table scraps from time to time, and we put out a cardboard box with an old towel this afternoon(Some of the kittens have found their way to it) Any other thoughts?

- YES! My neighbors had the same thing - feral cats and kittensThey first set out boxes with warm, electric blankets (unless it will get wet, then just regular blankets) and food nearbyThis is the important part: They took a neighborhood collection and a safe trap, caught each cat/kitten - one at a time, and had them fixed at a local vet who did the procedure for very cheap because the cats were feral Do NOT let these cats continue to breedIt is so cruelWe had dead kittens all over our neighborhood beforeThis solved the problem completely.

- Q:what are foods that contain low carbs, high fiber and low fats?

- I honestly do not advise deep frying if it is your first time making a turkeythose prefer to be watched in any respect situations and they are frequently risky if no longer dealt with goodi'd advise procuring a cheap roaster pan (i exploit the aluminum ones that consistently bypass on sale round this time) Then get a Reynolds Turkey Bag and positioned it in thereit is really a lot ahrd to shrink to rubble once you do it that wayuntil eventually you over prepare dinner it/less than prepare dinner itI did that for my first time very last year and it change into suitable.

- Q:How do i add insulation to a very cold attic room?

- yoga may be relaxing but you can also get a good workout an hour of yoga can burn up to 350 calories

- Q:I really feel like making crafts but idk how! lol i have paper, pipe cleaners, neon index cards, some stirophone balls, those little pompom things,like this metal twine or sumtin and markers and crayons, and like old shirtswhat can i make out of those things?

- Use big dish washing gloves and black garbage bags then call local trash place to get their policy

- Q:How do you remove old blown in insulation so you can put in new quot;rolledquot; insulation? Don't want to mix the two.

- Removing this type of insulation is a long and labor intensive process you will be left with literally dozens of garbage bags full of the insulationthen you will have to vaccuum the spaces it was inWhy not roll over top with perhaps a plastic sheet separating the two the added R-value is always a good idea.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Ceramic Fiber Refractory Insulation 25mm Thickness Blanket, 96 Bulk Density

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 200 kg

- Supply Capability:

- 5000000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords