Ceramic Fiber Paper For Gasket High Temperature

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 roll

- Supply Capability:

- 6000 roll/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

| Place of Origin: | Shandong, China (Mainland) | Application: | Refractory | Thickness: | 1-6mm |

| Width: | 600-1200mm | Length: | 10000-60000mm | Grade: | ST (Standard) |

| Chemical Composition: | aluminia,silica | Ultimate Strength (≥ MPa): | 0.3 | Working Temperature: | 1100/1200C |

| Fiber Diameter: | 3-5 | Brand Name: | LUYANGWOOL | Model Number: | LYTX-1260RZ |

Packaging & Delivery

| Packaging Details: | Wrapped by plastic bag and put into carton box Neutral packing is also available. carton size: 320x320x620 330x330x630 pallet size: 1280x1000x2300 1240x320x320 |

| Delivery Detail: | Within 10~20 days |

Specifications

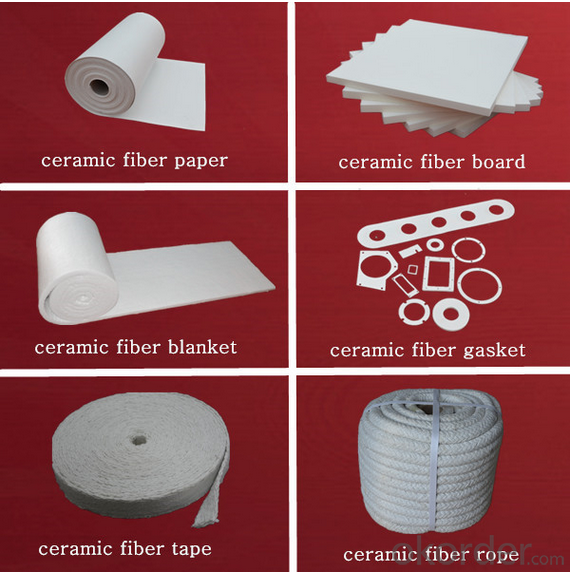

Ceramic Fiber Paper

Density: 200-250kg/m3

Thickness: 1~6mm

Temperature:1260-1350C

Customized service is also available.

Ceramic fiber paper is a lightweight refractory material processed from a blend of high purity alumina-silica fibres into a highly flexible, uniform sheet. It is recommended for classfication temperatures up to 1260C. Ceramic fiber paper has low shirngkage, good handling strength, and low thermal conductivity. It contains a small amount of orgainc binder for processing which makes it flexible, and reduces off-gassing and odour during use. Our product has a highly uniform structure due to its controlled basis weight and thickness, assuring homogeneous thermal conductivity and a clean, smooth surface ideas for gasket or sealing. Ceramic fiber paper is completely free of asbestos, and is designed to be an economic replacement for asbestos paper in most applications. Ceramic fibre paper is easy to cut with a knife, shears, or standard steel rule dies. Its flexibility allows it to be wrapped or rolled to fit most complex configurations.

Technical Data Sheet

Description | STD Paper | HT Paper |

Chemical Composition (%) | ||

Al2O3 | 47 | 48 |

SiO2 | 52 | 51 |

Fe2O3 | ≤0.5 | ≤0.5 |

Na2O3 | ≤0.2 | ≤0.2 |

Physical Properties | ||

Density (kg/m3) | 200 | 250 |

Classification Temperature ( 0C ) | 1260 | 1430 |

Maximum operating temperature ( 0C ) | 1100 | 1200 |

Organic matter content (%) | ≤9 | |

Color | White | |

Loss Of Ignition(%) | ≤10 | |

Tensile Strength (Kpa) | ≥0.3 | |

Standard Specification

Width: 610/1220mm

Thickness: 1/2/3/4/5/6mm

Density: 200-250kg/m3

- Q:Which is the best insulation effect of ceramic fiber paper and XPE insulation film?

- The insulation effect depends on the temperature. The same material, the temperature is different, thermal conductivity is not the same. At low temperatures, I suggest you use XPE. Ceramic fiber paper is generally used for hundreds of degrees or even thousands of degrees of high temperature.

- Q:Where is the best packing area for ceramic fibers?

- As the temperature continues to rise, the products will gradually become white, organic fiber has been completely carbonized products completely for the high temperature inorganic ceramic fiber resistant ceramic fiber (standard type) white maximum temperature ceramic fiber cloth content index color 1260 C fiber diameter 1-4 m thermal shrinkage (1232 C, 24h) 3.5% transmission rate (at 538 8pcf) three 0.130w/m.k two aluminum oxide content 45-48% 0.7-1.2% ferric oxide content of calcium oxide and sodium oxide content of 0.43% slag ball content <8.5% breakdown voltage 5 kv/mm resistance of 5 * 1010 ohm 3w.xxceramic content index white color thickness 1.5mm--6.0mm single 0.5 3kg/ square meters of organic fiber content <20% content <2% strengthening materials alkali glass fiber nichrome wire (1Cr18Ni9Ti)

- Q:What are the materials for making ceramic fibers?

- In recent years, because of the global energy prices continue to rise, energy saving has become a China national strategy background, than the insulation bricks and other traditional refractory pouring material such as 10-30% ceramic fiber has been more and more widely used in the domestic Chinese, development prospect is very promising. Throw carpet and spray carpet difference

- Q:What fiber glass made of ceramic fiber paper?

- The raw material of the ceramic fiber paper is the ceramic fiber cotton as the basic raw material, and the unique injection process cotton is preferred.

- Q:Which insulation effect is better compared with ceramic fiber for STP insulation board?

- Solid energy saving STP insulation board, its insulation performance than traditional ceramic fiber insulation material is better than 3~4 times

- Q:What are the prospects for ceramic fiber paper and how much investment will be needed?.

- It's a good prospect. I have friends around here who specialize in this. Not much investment.

- Q:How are ceramic fiber papers attached to the interior wall?

- There are two ways to apply ceramic fiber paper to the wall. The first is to buy ceramic fiber paper with single-sided adhesive tape, and the second is to paste it directly with double-sided adhesive tape. From Ji'nan dragon hot ceramics limited liability company, refractory materials chapter

- Q:Are ceramic fiber paper permeable?

- However, in the case of water can not play a good insulation effect, but the use of ceramic fiber paper temperature is about 1000 degrees, there will be no water, Ji'nan Sheng Yang ceramic fiber manufacturers

- Q:Do fiberglass or ceramic fiber paper have insulation effect?

- Second, in the case of temperature can be met, glass fiber cotton insulation better. The main advantage of ceramic fiber is to make gaskets and the like.

- Q:The difference between ceramic fiber cloth and ceramic fiber paper?

- Appearance。 The ceramic fiber cloth has an obvious grid like appearance, and the ceramic fiber paper is very few or even mesh like.Density. The density of ceramic fiber paper is greater than that of ceramic fiber cloth.Thickness. Ceramic fiber paper, the thinnest can do 0.5mm, ceramic fiber paper can not do so thin, generally thin, there are also 2mm.Stand upright。 Ceramic fiber paper can be like in our life that can be placed on the A4 paper, mold, stand up. The ceramic fiber cloth is like the cloth used in our life. It is very soft and has no standing.Tear resistance. The toughness of the ceramic fiber paper is not as good as that of the ceramic fiber cloth.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Ceramic Fiber Paper For Gasket High Temperature

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 roll

- Supply Capability:

- 6000 roll/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords