Ceramic Fiber Module with High Quality Made in China

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 4 pc

- Supply Capability:

- 50000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

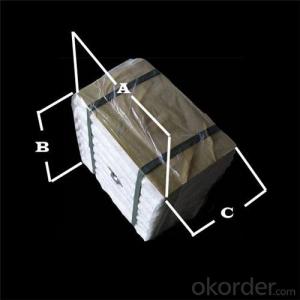

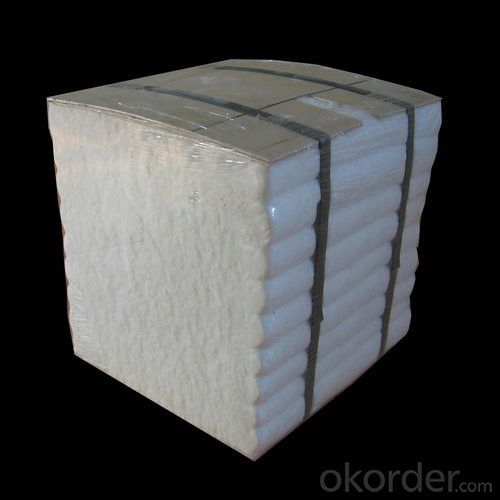

Composite of Ceramic Fiber Module with High Quality Made in China

Ceramic Fiber Module with High Quality Made in China are made from the corresponding ceramic fiber material acupuncture blanket processed in dedicated machines according to fiber component structure and size.

In the process, a certain proportion of compression is maintained, in order to ensure modules expand to the different directions after completion of ceramic fiber folded module wall lining, to create mutual extrusion amongst modules and form a seamless whole unit. Ceramic fiber folded modules is directly fixed in industrial furnaces shell plate by various anchorage.

Ceramic Fiber Module with High Quality Made in China: ordinary type, standard form, high-purity type, high-alumina type and containing zirconium type. Different types of products used different materials. Performance of Ceramic Fiber Module with High Quality Made in China also has difference, and they are suitable for different working temperatures.

Main Features of the Ceramic Fiber Module with High Quality Made in China

◆Low thermal conductivity

◆High tensile strength

◆Resilient to thermal shock

◆Corrosion resistance

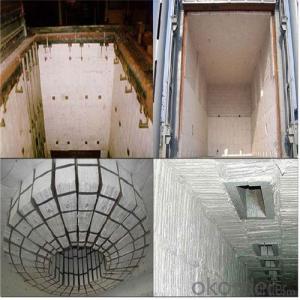

Application of Ceramic Fiber Module with High Quality Made in China

◆Petrochemical process heater refractory fiber lining

◆General furnace backup insulation

◆Heat treating furnace or intermittent(shuttle) kiln hot face lining

◆Electrical insulator

◆Heat seals for kiln car or furnace door

◆High temperature acoustic

◆Fire protection

Ceramic Fiber Module with High Quality Made in China Images

Ceramic Fiber Module with High Quality Made in China Specification

Type | STD | HP | HA | HZ | |

Classification Temperature (°C) | 1260 | 1260 | 1350 | 1430 | |

Working Temperature (°C) | 1050 | 1100 | 1200 | 1350 | |

Color | Spotlessly white | spotlessly | spotlessly | spotlessly | |

white | white | white | |||

Density (kg/m3) | 160-200 | 160-200 | 160-200 | 160-200 | |

Shrinkage on heating (%) | -3 | -3 | -3.5 | 3.5 | |

(24 hours, density as 128/m3) | (1150°C) | (1250°C) | (1300°C) | (1350°C) | |

Thermal conductivity by different temperature (w/m.k) (density as 128kg/m3) | 0.15(800°C) | 0.176(800°C) | 0.18(1000°C) | 0.23(1000°C | |

0.17(1000°C) | 0.22(1000°C) | 0.26(1200°C) | 0.31(1200°C) | ||

Tensile strength (MPa) | 0.04 | 0.04 | 0.04 | 0.04 | |

(density as 128kg/m3) | |||||

Chemical | AL2O3 | 45-47 | 45-46 | 53-55 | 38-54 |

composition | AL2O3+SIO2 | 98.5 | 99 | 99 | 82-90 |

(%) | ZrO2 | - | - | - | 10-18 |

FAQ of Ceramic Fiber Module with High Quality Made in China

Q1:Are you a manufacture or trader?

A:Factory+trade(mainly factories,at the same time,we operates other related products).

Q2:Can we visit your factory?

A:Sure,welcome at any time,seeing is believing.

Q3:What's the MOQ of trial order?

A:No limit,We can offer the best suggestions and solutions according to your condition.

Q4:Is your company accept customization?

A:We have own factory and excellent technical team,and we accept OEM service.

Q5:How about your company's certification?

A:ISO9001 and Test Report,also we could apply other necessary certification.

Q6:How to slove the quality problems?

A:If the products are not confirmed to customer samples or have quality problems,our compay will be responsible to make compensation for it.

- Q:If a person has IBS, how do you control the diarrhea ?

- Engine pulleys, elevators, cranes, boom liftsOtherwise yahoo search pulley

- Q:Please, answers should pertain to a metal building meeting the following specifications:30'W X 40'L X 16'HNO INSULATIONlittle or no shadepainted with white paintBuilding is located in east Texas, a hot humid area.So, what is the best combination for reducing interior temps on hot days:(1)turbine roof ventilators and ceiling fans(2)turbine roof ventilators and exhaust fan mounted in the wall(3)regular roof vents and exhaust fan mounted in the wall(4)regular roof vents and ceiling fansIf you can think of another combination THAT DOESN'T INVOLVE AIR CONDITIONING OR INSULATION, please shareThanks:-)

- To beat fatigue after your workout, enjoy this smoothie pre-workout, then eat the sandwhich post-workout Super Smoothie 1/2 cup orange juice 1/2 cup soy milk 1/2 cup fresh Strawberries Blend on high one minute or until smooth Jolt Sandwich 1 slice whole-grain bread 1 Tbsp almond butter 1 tsp honey Spread the bread with the almond butter, drizzle with honey and fold over.

- Q:I seem to sweat alot even when its freezing cold in my roomi tried using different blankets but it is all the same

- Night sweats can be a sign of a serious illnessGo to your doctor and ask his adviceAlso, some people sweat a lot at nightDo you wear pajamas to bed? Maybe you need looser fitting ones made of a natural fiber.

- Q:What is the difference between aluminium silicate needled blanket and aluminium silicate fiber felt?

- Aluminum silicate needled blanket is made of high-quality coke stones by more than two thousand degrees Celsius temperature of melting and solidification into fusion with other additives and have many special properties, such as, good extensibility, strong shock resistance, light weight, excellent heat insulation, good stability, no deformation at high temperature to several thousand degrees, so aluminum silicate needled blanket is often used in the chemical industry, construction industry, electronic industry, aerospace industry, military industry, air conditioning and refrigeration etc..

- Q:I want to get more fiber into my system! BUT what has a lot of fiber? i have NO idea! anything thats HEALTHY and GOOD that i can mix into my water? or maybe some snacks that are healthy and high in fiber? ANYTHING! thank you! :)

- Hey guy I would not be so disrespectful to mars like that sooner or later Earth maybe beneath chance and also you would ought to transfer there, in the event you maintain being nasty to mars the martians would deny your visa program.

- Q:i'm having work done on my unit and the contractor is using fiberglass insulation that does not have paper backingit is R-13, which I read is the correct rating for wallsi also see that it's bunched up in places, especially around electrical boxes, stuffed over wires, and that there are voidsany pros out there that can help? thanks.

- R-13 or R-15 is standard for exterior walls, it should not be bunched up around anything it is designed to insulate best when fully expanded, the installer shoud have cut out around electrical boxes, and there shoud not be any voids, any thing that can not be filled with insulation should be filled with a foam in a can productas far as running it over wires that will offer the best insulation as apposed to cutting around the wires

- Q:and im too scared to put anything up thereweather it be the cream in the tube or those pessarie thingsi tried taking the oral tablets but it didnt work (my doctor also told me that tablets arent always as effective as the cream)how else can i get rid of my thrush?

- maybe if you like being artistic, buy some painting supplies or maybe a Latchhook or something that you can work on to keep you busy over the summerMaybe make friendship bracelets? those are fun

- Q:Trying to decide between osb strand board and composite siding panels each 7/16quot; which has better insulation value?There is a huge price difference, (osb $8, siding $19-4x8 sheets) both need primed and paintedThe siding would look better but I don't care about thatThe insulation value is what I'm interested in.

- c) is the correct answer, i believe.

- Q:My husband and I are trying to lose weight and I was just looking around for some healthy recipes and any tips anyone might have to help lose weight and keep it offand also does anyone keep a food diary?? Just writing down eveything that you eat everyday I think I heard about this on Tyra?? Has anyone tried using one or ever heard of it????Thanks.

- Formula for Success: 1Small Frequent Meals Don't skip meals or go more than four hours without eating this set you up for later temptationWhen meals are more than six hours apart, plan strategic snacks 2Eat Moderate Portions Eat a little less of everything! 3Beware of Concentrated Sugars Excess sugar eaten alone causes more insulin secretionInsulin promotes fat storage and can result in a rebound drop in blood sugar levelsLow blood sugar, in return, stimulates the appetite, especially cravings for more sugar 4Eat Foods High in Fiber Fiber fills you up and helps stabilize blood sugar levelsThere are two types of fiber: soluble and insolubleWe need both of them in our diet! 5Lower Your Fat Intake Limit foods that are high in fat 6 Consume Caffeine in Moderation, If at All Caffeine, like alcohol, may be contained in beverages considered to be food but the effects of this chemical are definitely drug-like 7Exercise at least 3 times a weekWalk, walk, walk, or Run!!! Drink Plenty of waterUse the charts below to determine your appropriate weight and caloric intakeA recipe site, from the Mayo Clinic is included.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Ceramic Fiber Module with High Quality Made in China

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 4 pc

- Supply Capability:

- 50000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products