Ceramic Fiber Module for Ceramic Kiln Made in China

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 8 pc

- Supply Capability:

- 50000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Composite of Ceramic Fiber Module for Ceramic Kiln Made in China

Ceramic Fiber Module for Ceramic Kiln Made in China are made from the corresponding ceramic fiber material acupuncture blanket processed in dedicated machines according to fiber component structure and size.

In the process, a certain proportion of compression is maintained, in order to ensure modules expand to the different directions after completion of ceramic fiber folded module wall lining, to create mutual extrusion amongst modules and form a seamless whole unit. Ceramic fiber folded modules is directly fixed in industrial furnaces shell plate by various anchorage.

Ceramic Fiber Module for Ceramic Kiln Made in China: ordinary type, standard form, high-purity type, high-alumina type and containing zirconium type. Different types of products used different materials. Performance of Ceramic Fiber Module for Ceramic Kiln Made in China also has difference, and they are suitable for different working temperatures.

Main Features of the Ceramic Fiber Module for Ceramic Kiln Made in China

◆Low thermal conductivity

◆High tensile strength

◆Resilient to thermal shock

◆Corrosion resistance

Application of Ceramic Fiber Module for Ceramic Kiln Made in China

◆Petrochemical process heater refractory fiber lining

◆General furnace backup insulation

◆Heat treating furnace or intermittent(shuttle) kiln hot face lining

◆Electrical insulator

◆Heat seals for kiln car or furnace door

◆High temperature acoustic

◆Fire protection

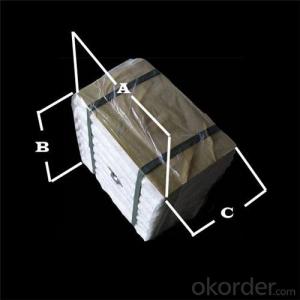

Ceramic Fiber Module for Ceramic Kiln Made in China Images

Ceramic Fiber Module for Ceramic Kiln Made in China Specification

Type | STD | HP | HA | HZ | |

Classification Temperature (°C) | 1260 | 1260 | 1350 | 1430 | |

Working Temperature (°C) | 1050 | 1100 | 1200 | 1350 | |

Color | Spotlessly white | spotlessly | spotlessly | spotlessly | |

white | white | white | |||

Density (kg/m3) | 160-200 | 160-200 | 160-200 | 160-200 | |

Shrinkage on heating (%) | -3 | -3 | -3.5 | 3.5 | |

(24 hours, density as 128/m3) | (1150°C) | (1250°C) | (1300°C) | (1350°C) | |

Thermal conductivity by different temperature (w/m.k) (density as 128kg/m3) | 0.15(800°C) | 0.176(800°C) | 0.18(1000°C) | 0.23(1000°C | |

0.17(1000°C) | 0.22(1000°C) | 0.26(1200°C) | 0.31(1200°C) | ||

Tensile strength (MPa) | 0.04 | 0.04 | 0.04 | 0.04 | |

(density as 128kg/m3) | |||||

Chemical | AL2O3 | 45-47 | 45-46 | 53-55 | 38-54 |

composition | AL2O3+SIO2 | 98.5 | 99 | 99 | 82-90 |

(%) | ZrO2 | - | - | - | 10-18 |

FAQ of Ceramic Fiber Module for Ceramic Kiln Made in China

Q1:Are you a manufacture or trader?

A:Factory+trade(mainly factories,at the same time,we operates other related products).

Q2:Can we visit your factory?

A:Sure,welcome at any time,seeing is believing.

Q3:What's the MOQ of trial order?

A:No limit,We can offer the best suggestions and solutions according to your condition.

Q4:Is your company accept customization?

A:We have own factory and excellent technical team,and we accept OEM service.

Q5:How about your company's certification?

A:ISO9001 and Test Report,also we could apply other necessary certification.

Q6:How to slove the quality problems?

A:If the products are not confirmed to customer samples or have quality problems,our compay will be responsible to make compensation for it.

- Q:I have a project where i have to keep hot things hotWhat things/materials should i use and how should i use them?

- Wow that is allot of stuffDo you have a cart for that thing it must weigh a ton After camping with the Boy Scouts for many years I have found that you will not need half of the things on that list half of the timeHere is a list of stuff in most Boy Scout Patrol BoxesLarge Pot ( for stews and heating up water ) Small pot ( Same ) Pan ( For small cooking Frying ) Skillet ( for frying large dinners ) Cooking utensils- spatula, knife, tongs, spoon, fork 3 Large tubs ( For Dishes ) First Aid kit Frisbees ( Yes Frisbees ) they make a great bowl or plate, and it is a game to play other wiseMatches Paper ( for fires ) Soap Not allot but not allot is needed when you are roughing it.

- Q:My house is facing E-W and getting direct sun all day here in FloridaI just finished siding last Sumer by using a insulation with tight dead air space, my bed room window facing the East has blind shut all day to block the sun, however, my bed room gets hotter than the rest of the room, plus entire indoor house is hotter than even out side especially in the eveningWhy is this, and what can I do ? (do not wish to spend money too much since I just finish putting $30K into this home.

- I just replaced both my windows and insulated my ceilingThe insulation made a big impact right awayThe windows are much less of an areaI would insulate the walls because more heat and cold can be lost though thereAs for the windows, do the best you can to seal up leaksCaulk is cheap and if you can seal the leaks that is the biggest problem with windowsNewer windows do help, but the insulation and a bit of caulk would be much more effective.

- Q:So my child had a very high fever and chills the other day and I didn't know exactly how to treat him so I took him to the docsBut just wondering, he was shivering saying hes really cold but i couldnt put a blanket on him because of his feverso what do you do??? apart from giving him fluids, i can't really just sit there and watch him shiver because he's cold but really can't do anything because of his temperatureI gave him a lukewarm bath and he calmed down but then it came back again.It's just I hate going to the doctors and they tell me stuff I already know like give him plenty of fluids and give him medicine etc etc any mothers help would be nice thanks

- You can still put a blanket on him, just make sure his feet are uncovered because heat from the body escapes from your head and feetIf you still don't feel comfortable putting the blanket on him just give him a sheetThen he will be more comfortable and you won't have to worry.so no worries mommy! Hope he gets better soon and you don't worry so much :)

- Q:Okay, so I bought this bag of yarn from a consignment storeThere were two small balls of this soft, dark green yarn that was absolutely gorgeousIt was a dark moss green, that had flecks of sapphire blue when held up to the lightIt's soft and a worsted weightI have absolutely no idea what kind of yarn this could be or if they even make it anymoreBut if anyone has any idea what it could be, could you tell me? Thank you!

- I am 15.and i am 56.and i DID weigh 150.but i lost 25lbs.i was the same exact weight.what i did was i got a workout offline.the Jessica Alba workout.and i ran ( treadmill,elliptical,bike) for 45 minutes - 1 hour.i started out only doing 20 minutes then gradually got to where i could do it for longer.then i got 10 lb dumbells and lifted them for 4 reps of 10.and last i did 50 crunches, and 50 sit ups.i lost all of that weight in about 6 weeks.Good Luck!

- Q:I've tried a few different ways of losing wieght but all of them have been kinda the sameI have just tried excersice methods but i also hear that there are others such as special drinks, sauna boothsetc?

- It seems undesirable to have pictures of all and sundry who's banned from college property on each and every development on campusIt make the campus seem riskyThey probable have their pictures in some records-base on the campus police deptexcept somebody sees them and is attentive to for a actuality they are banned and comments them they are in a position to probable ruin out with a lotThat'd be my wager a minimum of.

- Q:Ceramic fiber felt 1050 type practice, according to what?

- Aluminum silicate is a mineral material and another name is ceramic fiber.

- Q:For a horse that isn't clipped and is mostly in a barn what temperature do you start to blanket??

- make a humidity hide

- Q:baby blanket .I am only a beginner.for example dk/chunky etc.

- Bake from scratch I doubt it will cost much more! ASIC SPONGE MIXTURE Ingredients: 4oz / 120g butter 4oz / 120g fine white sugar 4oz / 120g white self raising flour 2 eggs 1 tablspn milk Method: Preheat the oven to 180 / 350 / 4 Beat the butter and sugar together until it is pale and fluffy (at least 5 minutes and prefereably more with an electric mixer) Beat in the eggs and one tablspn flour Beat in the flour Beat in the milk Grease a pan, fill with mixture and bake until golden and springy [15 - 20 minutes] do not open oven until then as it may fallAllow to cool To make a simple topping either icing [confectioners sugar I think you call it] mixed with a little water and beaten ferociously or butter creme topping with butter and sugar beaten together with flavour if you like.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Ceramic Fiber Module for Ceramic Kiln Made in China

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 8 pc

- Supply Capability:

- 50000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products