CERAMIC FIBER INSULATION BLANKET 2300 FOR WOOD FIRED PIZZA

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 2000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

General Information of Ceramic Fiber Blanket

l CMAX ceramic fiber blanket is made from high Kao-Ling clay, high purity alumina and silica oxides by spun or blown process.

l Ceramic fiber blanket is asbestos free. Double-side needling provides ceramic fiber blanket with great tensile or handing strength for easy installation.

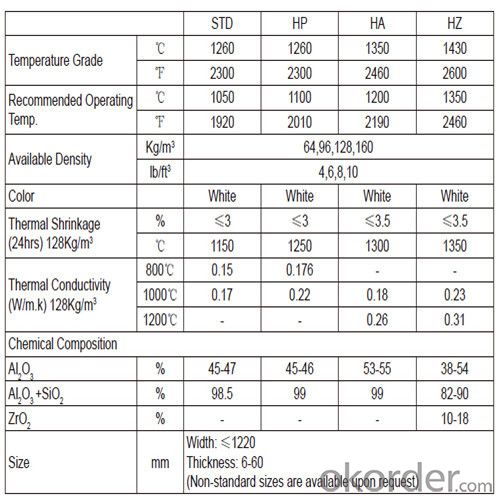

l Ceramic fiber blanket are classified as STD, HP, HA, and HZ respectively corresponding to different maximum service temperature 1000℃, 1100℃, 1200℃ and 1350℃

Feature of Ceramic Fiber Blanket

Heat resistance

Light weight

Low thermal conductivity

Image of Ceramic Fiber Blanket

Technical Data of Ceramic Fiber Blanket

Q5: Can you give me a brief introduction of the application of your products?

A5: CNBM (China National Building Material) core refractory business comprises the production, sale and installation of high-grade refractory products, the development and implementation of customized system solutions as well as rendering outstanding services for the key industries in Glass, Iron& Steel, Petrochemical, Cement, Ceramic and Nonferrous Metals.

Why Choose Us

l We have more than 11 refractory production facilities and bases across China. We have a wide products range, such as ceramic fiber products (ceramic fiber blanket, module, board, paper, bulk), ceramic fiber textile (ceramic fiber rope, cloth, tape, yarn) etc, refractory brick (fireclay brick, high alumina brick, silica brick, magnesia brick etc), monolithic refractory materials, insulating fire brick, calcium silicate board, mica sheet, steel fiber. You can find various products here, and we can combine the light weight ceramic fiber products with the heavy weight refractory brick in one container delivery, then save the sea freight for you.

l We are a government owned company with ISO certificate.

FAQ

Q1: How do you control the products quality?

A1: With strict quality control system throughout the materials selection and production process, our refractory and ceramic fiber products quality is effectively controlled to meet customer requirements.

Q2: Can you offer Door-to-Door delivery?

A2: Yes, but only for some countries such us U.S., UAE, Saudi Arabia, Iran, and Russia, etc.

Q3: What is the minimum quantity?

A3: There is no minimum order quantity. Depending on the item and processing, there may be a minimum production required, however we can offer a quotation based only on the quantity you need.

Q4: What`s the lead time for my order?

A4: It depends on customers’ requirements and our production schedule. And usually 30-60 days for refractory bricks,10-25 days for unshaped refractory materials and 10-20 days for ceramic fiber blankets.

- Q:with a hair straightner , step by step and also tips on getting it extra straignt and smooth.

- Go for it if you can afford itMy son has a Mac book and loves it.

- Q:do ceramic cook tops crack on their own?

- Fruit, vegetables, oatmeal, whole grain bread.

- Q:what is a breathable fabric that could be used to keep an attic cooler?

- Check out tankless water heatersThey are cheaper to operate and you will never run out of hot waterI also think you may get to right off part of the price on your taxesJust a thought.Good Luck.

- Q:I've never owned a dog before, but I've decided that I'd really like to have a chihuahuaI've seen a lot of prices, whats the normal price for a chihuahua? I'm planning on doing obedience training, crate training, loose leash, etcAny advice? Warnings? Do they really bark a lot?

- It's not chemistry it's geometry h x l x w volume 10 cm x 10 cm x ? cm 0.555 cm3 That's it!

- Q:both my parents have strat hair and some how im starting to have wave hair and i dont like it how can i make my hair go backand no i dont want to use a hair strataner that fries your hairare there any shamoops? or any prodectsomething under 30 bucksplease!

- Yes, it is possible, but like another answerer said, impracticalYou could use thousands of mirrors, each on actuators that would position the mirror as the sun moves so that it reflects sunlight to a specific spotThis works well for mirrors that are relatively close together, but as you get further away from the point you are focusing the light on, it become increasingly difficult to focus the lightAt some point it become more economical to simply build multiple large lenses rather than just one large lensYou can start small by making parabolic troughsThey don't have to be perfect, and you can coat them with mylar (which reflects sunlight very well)With just a few square meters you can really heat things upYou can heat things to 6000F pretty easily which will melt most metals pretty well.

- Q:in order to make cashmere and other clothing with furs, do they need to kill the animal?

- For garments made of yarns that are knitted or woven, no they don't kill the animalIt doesn't make sense to kill the source of the fibersThey are shaved, combed, sheared or de-furred, then allowed to grow a new coat that can be combed or shorn or cut and the fiber can be made into more yarn and so on and so onSome animals that produce particularly luxurious fibers of the higest quality are pampered and treated like princesses or princes with special diets, special accommodations, etcFor wools, cashmeres, angoras alpacas and other yarn based textiles, no animals are killed.

- Q:What kind of merchandise would a store have that sells needlepoint, fabric, wool ?

- 1omg the world's ending already? 2i'd be her wing(wo)man 3run to the kitchen and get the food processor and say u mean this right? 4myself in 20 years 5why are there so many atheists? 6wasabi 7hey that's the guy from the commercials! 8myspace pictures!!! lol 9throw up so i could get myself back to the modern agei'm not keen on getting eaten by a t-rex 10the wallet, i got my id and junk in there

- Q:we currently have aluminum sidingOur windows are wooden, and some have quite a bit of damage.Which one would save us more money on energy?Which would improve the value of our home more?If you were a buyer, would either be a big selling point for you?

- From any energy savings standpoint, the insulation will have the greatest impact on your energy consumptionSIR (Savings to Investment ratio) values are typically in the double digit range wheras windows are typically a break even 1:1 (based on a 10 year paybackInterpretation: insulation 14:1 SIR money saved in unpurchased energy returns the cost of the insulation in less than on year (A 10 would be a year) Windows 1:1 10 years to return your initial expenseBut that is taking each item at its sole valueInsulation in conjunction with the window replacement (particularly a good double or triple paned, argon filled low e type window) will calculate out around 2 or 3:1 depending on the cost of the windowsGood quality intalled vinyl siding, properly installed with an undersheathing and continuous vapor barrier, while not a prime energy saver can help reduce bulk moisture infiltration, prevent air wash to existing insulation and give esthetic value to your home alsoSometimes it is a better idea to get all the options up frontThis is where a home energy anaylisis can be worth its weightbalanced breakdown of cost effective measures, and in some cases even tie ins to available financial grants and loans for specific energy measures installed by their recomendations.

- Q:In all seriousness, why does it matter to you what labor conditions are like in China?

- check out roxul safe and sound barrier and there is a sound barrier drywall available plus watch all plug outlets and switches on the common walls sound will travel through them

- Q:I've never been able to blow my hair straight properlyUsually I just use a comb and the blow dryer and just sort of work through it until i recently learned that a proper brush actually makes a difference so I went to buy a brush but I got so confused with all these options ceramic, anti bacterial, bristle brush, nylon brush, holes, no holes.etc! Can someone help me please? are there any known brands? what should i look for in a brush??thx!

- Pre heat grillLightly toss with olive oil, sea salt and black pepper, Cook under very hot grill until just slightly charedsprinkle with freshly grated Parmesan cheeseEnjoy!

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

CERAMIC FIBER INSULATION BLANKET 2300 FOR WOOD FIRED PIZZA

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 2000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords