Ceramic Fiber Castable For Fireplace and Industrial Furnace

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 kg

- Supply Capability:

- 3000000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Ceramic Fiber Castable For Fireplaces and Industrial Furnaces

Product Description:

Ceramic fiber castable is manufactured according to international standards. The product is famous for its excellent abrasion resistance and low thermal conductivity. Further, these can be provided in different specifications as required by clients. Castables use high purity raw materials and additives as the main material, and are made with superfine powder adding technology.

Product Features:

The material has excellent structural stability and air tightness, and has high physical and chemical properties, and also excellent working ability. If should be used with the same material products.

Product Applications:

Widely used in various kiln linings, such as boilers, blast furnace hot blast stoves, heating furnaces, ceramic kilns, heat treatment furnaces, incinerators, re-circulating fluidized bed furnaces and chemical industry and construction industry furnaces.

Product Specifications:

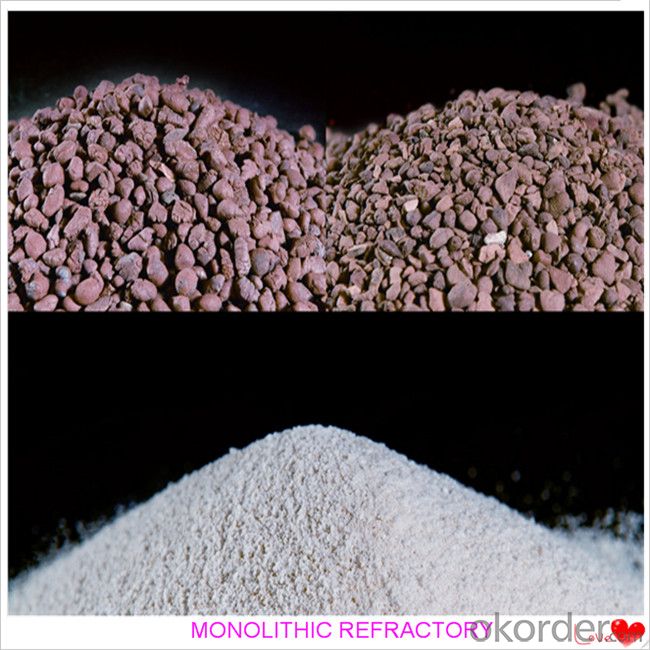

Product Images:

FAQ:

Q1: Why buy Materials & Equipment from OKorder.com?

A1: All products offered by OKorder.com are carefully selected from China's most reliable manufacturing enterprises. Through its ISO certifications, OKorder.com adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

- Q:How do monolithic refractories protect the lining of ladles and tundishes?

- Monolithic refractories protect the lining of ladles and tundishes by forming a strong and durable barrier against high temperatures, chemical reactions, and mechanical stresses. These refractories are designed to be resistant to thermal shock and erosion, ensuring that the lining remains intact and unaffected by the molten metal or slag. They also provide insulation, minimizing heat loss and reducing energy consumption. Overall, monolithic refractories act as a reliable shield, extending the lifespan of the ladles and tundishes and preventing any detrimental effects on the lining.

- Q:Can monolithic refractories be customized for specific iron and steel processing requirements?

- Indeed, monolithic refractories possess the capability to be personalized in order to satisfy the distinct demands of iron and steel processing. Renowned for their adaptability and versatility, monolithic refractories can be tailored to accommodate a wide range of applications. The formulation, tangible characteristics, and methods of installation can all be modified to cater to the specific necessities of iron and steel processing. For instance, the selection of raw materials employed in the production of monolithic refractories can be customized to endure the formidable temperatures and harsh chemical environments inherent in iron and steel processing. Diverse types of aggregates, binders, and additives can be chosen to augment the refractory's resistance against thermal shock, erosion, and corrosion. Moreover, the installation technique for monolithic refractories can be adjusted to suit the precise requirements of iron and steel processing. Whether it is gunning, casting, ramming, or spraying, the method of installation can be personalized to guarantee optimal performance and durability in the given application. Additionally, monolithic refractories can also be tailored to particular shapes and sizes to accommodate the various equipment and structures utilized in iron and steel processing. This facilitates a more precise and efficient lining of furnaces, ladles, tundishes, and other vessels, thereby enhancing overall productivity and performance in the process. In conclusion, monolithic refractories can be customized to cater to the distinct requirements of iron and steel processing by modifying their composition, tangible characteristics, installation techniques, and shape. This customization ensures that the refractories can withstand the extreme conditions encountered in these industries, resulting in improved performance, prolonged service life, and enhanced productivity.

- Q:How do monolithic refractories withstand the thermal cycling in coke oven applications?

- Monolithic refractories are able to withstand the thermal cycling in coke oven applications due to their high thermal shock resistance and low thermal conductivity. They have a unique composition and structure that allows them to expand and contract without cracking or spalling under extreme temperature fluctuations. Additionally, their dense and homogeneous structure minimizes heat transfer, allowing them to maintain their integrity and strength even in the harsh conditions of coke oven operations.

- Q:What are monolithic refractories and how are they different from other refractory materials?

- Monolithic refractories are a type of refractory material that is produced and applied in a single, unified form. Unlike other refractory materials, such as bricks or tiles, monolithic refractories are not pre-formed into specific shapes or sizes. Instead, they are generally composed of a mix of aggregates, binders, and additives, which are then installed in place and cured to form a solid, dense structure. One key difference between monolithic refractories and other refractory materials is their versatility and ease of installation. Traditional refractory bricks or tiles require skilled labor and careful assembly to create a lining or structure. Monolithic refractories, on the other hand, can be poured, sprayed, or gunned into place, allowing for a much faster and more efficient installation process. This makes them particularly suitable for complex shapes or areas that are difficult to access. Another difference lies in the physical properties of monolithic refractories. While bricks and tiles are typically characterized by their high mechanical strength and resistance to thermal shock, monolithic refractories can be tailored to exhibit a wide range of properties. They can be engineered to have excellent thermal insulation, superior corrosion resistance, or enhanced abrasion resistance, depending on the specific application requirements. This flexibility makes monolithic refractories suitable for a variety of industries, including steel, cement, glass, and petrochemical. Furthermore, monolithic refractories have the advantage of being able to expand and contract with temperature changes, unlike rigid brick structures. This thermal flexibility helps to minimize cracking and damage caused by thermal cycling, prolonging the lifespan of the refractory lining. Additionally, monolithic refractories offer better refractory integrity and reduced joint failure, as there are no seams or weak points that can be susceptible to thermal stresses. In summary, monolithic refractories are a versatile and convenient type of refractory material that can be customized to meet specific application requirements. Their ease of installation, thermal flexibility, and tailor-made properties make them distinct from other refractory materials such as bricks or tiles.

- Q:What are the limitations of monolithic refractories in high-temperature applications?

- Monolithic refractories are known for their versatility and ease of installation, making them popular in a variety of high-temperature applications. However, they do have certain limitations that need to be considered. Firstly, monolithic refractories have a limited thermal shock resistance. Rapid temperature changes, such as during startup or shutdown procedures, can cause thermal stress, leading to cracking or spalling. This can be a significant concern in applications where the refractory is subjected to frequent temperature fluctuations. Secondly, monolithic refractories have relatively lower mechanical strength compared to traditional brick or block refractories. This can result in reduced resistance to mechanical stress, such as abrasion or impact, particularly in high-temperature environments. Therefore, they may not be suitable for applications with high mechanical loading or abrasive conditions. Another limitation of monolithic refractories is their susceptibility to chemical attack. Certain aggressive chemical environments can cause chemical reactions with the refractory material, leading to deterioration or corrosion. This can be a concern in applications involving acidic or alkaline substances, where special refractory materials may be required. Furthermore, monolithic refractories can have a higher susceptibility to spalling or erosion caused by thermal cycling. The repeated expansion and contraction of the refractory material due to temperature changes can lead to the formation of cracks or gaps, making them more prone to erosion from gases or liquids. This limitation should be carefully considered in applications where long-term durability is essential. Lastly, monolithic refractories can be challenging to repair or replace compared to brick or block refractories. Once installed, it can be difficult to remove and replace a monolithic lining, especially in complex shapes or confined spaces. This limitation can result in longer downtime or increased costs for maintenance or repairs. In summary, while monolithic refractories offer several advantages in high-temperature applications, they also have limitations in terms of thermal shock resistance, mechanical strength, chemical resistance, erosion, and repairability. These limitations should be carefully evaluated to ensure the suitability of monolithic refractories for specific application requirements.

- Q:How do monolithic refractories contribute to the reduction of heat loss in iron and steel furnaces?

- Monolithic refractories play a crucial role in reducing heat loss in iron and steel furnaces. These refractories are designed to provide a continuous lining throughout the furnace, eliminating joints and seams that can result in thermal leaks. One way monolithic refractories contribute to heat loss reduction is through their excellent thermal insulation properties. They have low thermal conductivity, meaning they are effective at restricting the transfer of heat from the furnace to its surroundings. This insulation helps to maintain the high temperatures required for efficient iron and steel production within the furnace, while minimizing heat loss to the surrounding environment. Another way monolithic refractories contribute to heat loss reduction is by providing a protective barrier that prevents the escape of hot gases and molten metal. This barrier helps to maintain the integrity of the furnace lining, preventing any gaps or cracks that could allow heat to escape. By ensuring a tight and continuous lining, monolithic refractories reduce heat loss by keeping the heat contained within the furnace. Furthermore, monolithic refractories have high resistance to thermal shock and erosion, which are common challenges in iron and steel furnaces. These refractories can withstand rapid temperature changes, preventing any sudden cracks or failures that could lead to heat loss. Additionally, they are resistant to the corrosive effects of molten metal and hot gases, ensuring the longevity of the lining and maintaining its insulating properties over time. In summary, monolithic refractories contribute to the reduction of heat loss in iron and steel furnaces through their excellent thermal insulation properties, ability to provide a continuous lining, resistance to thermal shock and erosion, and protection against corrosive substances. By minimizing heat loss, these refractories optimize the energy efficiency and productivity of the furnace, ultimately leading to cost savings and improved overall performance in the iron and steel industry.

- Q:What are the typical applications of monolithic refractories in the iron and steel industry?

- Monolithic refractories are widely used in various applications within the iron and steel industry. These refractories, which are made of a single material, offer several advantages such as ease of installation, resistance to thermal shock, and excellent resistance to chemical attacks. Here are some typical applications of monolithic refractories in the iron and steel industry: 1. Blast Furnace: Monolithic refractories are used in the lining of blast furnaces, where they are subjected to extreme temperatures and chemical reactions. They provide thermal insulation, prevent erosion, and resist the corrosive effects of molten iron and slag. 2. Ladles and Tundishes: Monolithic refractories are used to line ladles and tundishes, which are vessels used for transporting and transferring molten metal. These refractories offer good thermal insulation and resistance to erosion and chemical attack, ensuring the integrity of the vessels. 3. Steelmaking Converters: Monolithic refractories are utilized in converters, which are used in the steelmaking process to convert molten pig iron into steel. These refractories provide protection against the high temperatures and aggressive chemical environments encountered during the process. 4. Electric Arc Furnaces (EAF): Monolithic refractories are used to line the walls and roofs of EAFs, which are used to melt scrap steel for recycling. These refractories offer excellent thermal insulation, resistance to slag erosion, and thermal shock resistance, ensuring the longevity and efficiency of the furnace. 5. Continuous Casting: Monolithic refractories are employed in the continuous casting process, where molten steel is solidified into a continuous slab or billet. These refractories line the walls and floors of the casting molds, providing thermal insulation and resistance to chemical attack from the molten steel. 6. Reheating Furnaces: Monolithic refractories are used in reheating furnaces, which are used to heat steel billets or ingots prior to further processing. These refractories provide insulation, resist high temperatures, and ensure uniform heating of the metal. Overall, monolithic refractories play a crucial role in the iron and steel industry by providing reliable and durable linings in various applications. Their ability to withstand extreme temperatures, chemical attacks, and thermal shocks makes them indispensable for maintaining the integrity and efficiency of the production processes.

- Q:How do monolithic refractories improve the durability of furnace linings?

- The durability of furnace linings is significantly enhanced by the unique characteristics and properties of monolithic refractories. Unlike traditional brick refractories, which are made up of individual bricks or tiles, monolithic refractories consist of a single, homogeneous structure. A key advantage of monolithic refractories is their ability to eliminate joints and seams, which are weak points in traditional brick refractories. These joints can lead to cracks and failures due to thermal expansion and contraction. In contrast, monolithic refractories are poured or gunned into place, creating a seamless lining that minimizes the potential for cracks. This seamless structure increases the durability of the lining and reduces its susceptibility to thermal stress. In addition, monolithic refractories exhibit excellent thermal shock resistance, which is crucial for furnace linings that experience rapid and extreme temperature changes. The monolithic structure allows for better heat transfer and distribution, preventing localized hotspots that can cause thermal shock and lining failure. This enhanced thermal shock resistance enables the furnace lining to withstand repeated heating and cooling cycles without significant damage, thus improving its overall durability. Furthermore, monolithic refractories offer superior resistance to erosion and corrosion. Furnace linings are often exposed to harsh chemicals, molten metals, and abrasive materials, which can cause erosion and corrosion over time. Monolithic refractories are specifically designed to resist these corrosive agents, protecting the lining from chemical attacks and physical wear. This resistance ensures a longer lifespan for the furnace lining and reduces the need for frequent repairs or replacements. Moreover, monolithic refractories possess better insulation properties compared to traditional brick refractories. They have lower thermal conductivity, meaning that heat transfer through the lining is minimized. This insulation property helps to maintain a more stable and uniform temperature within the furnace, reducing thermal stress on the lining and contributing to its longevity. To summarize, monolithic refractories enhance the durability of furnace linings by eliminating joints and seams, improving thermal shock resistance, providing erosion and corrosion resistance, and offering superior insulation properties. These materials are specifically engineered to withstand the extreme conditions inside furnaces, ensuring a longer lifespan for the lining and reducing maintenance costs in the long term.

- Q:How are monolithic refractories installed and repaired in iron and steel production facilities?

- Monolithic refractories are vital components in iron and steel production facilities, as they provide insulation and protection against high temperatures, chemical corrosion, and mechanical wear. The installation and repair processes for monolithic refractories in these facilities require careful planning, expertise, and adherence to safety protocols. When installing monolithic refractories, the first step is to prepare the surface by removing any loose material and cleaning the area thoroughly. This ensures proper adhesion of the refractory material. The surface may also need to be roughened or textured to improve bonding. Next, the monolithic refractory material is mixed with water or a binder to create a workable consistency. It is then applied to the prepared surface using various methods such as casting, gunning, ramming, or troweling. The choice of application method depends on factors such as the type of refractory material, the area being repaired, and the desired outcome. During installation, it is essential to carefully follow the manufacturer's instructions regarding mixing ratios, curing times, and drying temperatures. Improper installation can lead to reduced refractory performance, premature failure, and safety hazards. Repairing monolithic refractories in iron and steel production facilities is an ongoing process due to the harsh operating conditions and mechanical stresses they endure. When a refractory lining shows signs of damage or wear, it is crucial to address the issue promptly to prevent further deterioration. The first step in repairing monolithic refractories is to assess the extent of the damage. This can be done through visual inspection, thermal imaging, or non-destructive testing techniques. Once the damage is identified, the repair method can be determined. Minor repairs can often be carried out using patching materials. These materials are typically the same or similar to the original refractory composition and are mixed with water or a binder to form a paste. The paste is then applied to the damaged area and allowed to cure. For more extensive repairs, the damaged refractory material may need to be removed entirely. This can be done through mechanical methods such as chipping, grinding, or cutting. After the damaged material is removed, the surface is prepared as mentioned earlier, and new refractory material is installed using the appropriate application method. It is important to note that the repair process should be conducted by trained personnel with expertise in refractory installation and repair. Safety precautions such as wearing protective clothing, using proper tools, and following established procedures should always be observed. In conclusion, the installation and repair of monolithic refractories in iron and steel production facilities require careful planning, adherence to manufacturer's instructions, and expertise in refractory materials. By following proper procedures and promptly addressing any damage, these facilities can ensure the longevity and efficiency of their refractory linings, ultimately contributing to the smooth operation of their production processes.

- Q:How do monolithic refractories contribute to the overall efficiency of iron and steel production?

- Monolithic refractories play a crucial role in enhancing the overall efficiency of iron and steel production. These refractories, which are made from a single material, provide exceptional thermal insulation, resistance to high temperatures, and excellent mechanical strength. By lining the furnaces, ladles, and other equipment used in the production process, monolithic refractories help in maintaining and regulating the required high temperatures for melting, refining, and shaping iron and steel. This insulation reduces heat loss, minimizes energy consumption, and ensures a more efficient and cost-effective production process. Additionally, the mechanical strength of monolithic refractories allows for better protection against wear and tear, resulting in increased equipment lifespan and reduced downtime for repairs and maintenance. Overall, the use of monolithic refractories significantly contributes to the efficiency, productivity, and sustainability of the iron and steel production industry.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Ceramic Fiber Castable For Fireplace and Industrial Furnace

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 kg

- Supply Capability:

- 3000000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords