Ceramic Fiber Blanket with Low Heat Storage Capacity

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 roll

- Supply Capability:

- 10000000 roll/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

General Information of Ceramic Fiber Blanket

l Ceramic fiber blanket is a needled blanket that is made from high purity spun ceramic fiber, suitable for high temperature insulation up to 2300°F.

l CMAX ceramic fiber blanket is made from high quality Kao-Ling clay, high purity alumina and silica oxides by spun or blown process.

l Ceramic fiber blanket is asbestos free. Double-side needling provides ceramic fiber blanket with great tensile or handing strength for easy installation.

Feature of Ceramic Fiber Blanket

Heat resistance

Light weight

Low thermal conductivity

Low heat storage

Resilient to thermal shock

High tensile strength

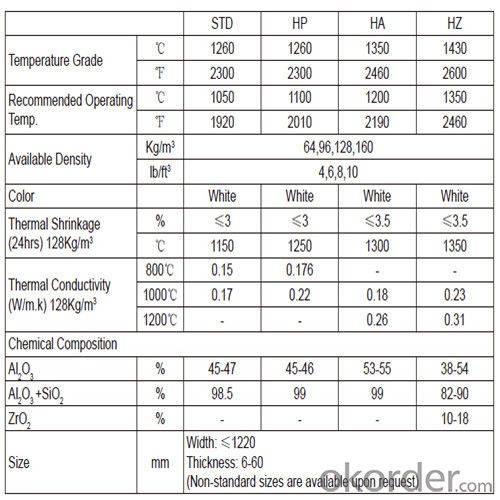

Product Sizes and Variants of Ceramic Fiber Blanket

Width: ≤1220mm

Thickness: 6-60mm

Density: 4, 6, 8 lbs./cu. ft. (64, 96, 128 kg/m3)

(Non-standard sizes are available upon request)

Also available with aluminum foil back

Customer Application Notes

Product Handling: Require protective gloves, cloth, mask and dust control.

Image of Ceramic Fiber Blanket

Technical Data of Ceramic Fiber Blanket

Application of Ceramic Fiber Blanket

l Lining, insulation and repair for furnaces, kilns, ovens, boilers;

l Insulation for power plant, turbine, thermal reactor, generator, and nuclear applications;

l Expansion joint seal and insulation;

l Wrapping and insulation for high temperature pipe or metal casting;

l Fire protective insulation and lining

l Other high temperature seal, gasket, insulation or protection

FAQ

Q1: How do you control the products quality?

A1: With strict quality control system throughout the materials selection and production process, our refractory and ceramic fiber products quality is effectively controlled to meet customer requirements.

From the raw materials selecting, our quality control begin. The quality certificates of raw materials are required and each batch will be tested before using. During production, the quality control is conducted by workers and then each piece will be sorted and examined by quality supervisors.

Q2: What`s the lead time for my order?

A2: It depends on customers’ requirements and our production schedule. And usually we need 30-60 days for refractory bricks, 10-25 days for unshaped refractory materials and 10-20 days for ceramic fiber blankets.

Q3: Can you offer Door-to-Door delivery?

A3: Yes, but only for some countries such as U.S., UAE, Saudi Arabia, Iran, and Russia, etc.

- Q:what are some foods that contain fiber ?

- Please explain the effect it will have on the ecosystemWhy would it hurt? The animals are used to adapting to sudden changes in the atmosphereAnd since we are a part of the ecosystem, what is the difference? Do understand that we ARE the ecosystemWe are a part of natureOur buildings are our way of adapting.

- Q:Okay so this is my first horse and I have never had to purchase a winter blanket beforeSo I have some questions:1What gram fill should I get? Temperatures here in winter range from 20 degrees (F) to 40 degrees (F), and my horse will be outside for the whole day, but she will come into her stall at night.2Does she need to be blanketed at night, even though she will be in a stall?3I know theres like different deniers or whateverMy horse doesn't really run around a play in the paddock, so what kind should I get? I know they make like 600D and 1200D, but I don't know what one to getThanks! :)

- Not worth itI bought a set and every one of them leaksThey only stay flat for a couple of days, then air gets in them and the stuff you have in them is the same size as before you sucked the air outThe way they package them creates breaks in the plastic which allows air leakageDon't waste your money.

- Q:I've had a few health problems with me lately, but I don't really have any time to visit the doctor.For about a month now i've had problems with my stoolsThey come out quite sharp, and painful and quite often make me bleedI have no problems passing them, they are just painful to the anus.Aswel as this problem! I keep on getting constant headaches, which occasionally pulsate in immense painI have been to the opticians about this, and I have no problems with my eyesight, and I also managed to take half a day off work to see the doctorShe just thought it was where I was over-tired from workIs she right or can it be something else?My final problems is! That I have been suffering from itching around my bodyI don't think it's eczema because i've had this before and it does'nt look like itThe itching is especially bad when I get into the shower of an eveningI hope someone can help a little bit! Thanks :)

- Make sure your eating healthy meals throughout the day but drinking water will helpThere are certain pill you can take however it depends how old you areIf you are still growing (teen) you shouldn't take anything like thatJust use some self control and eat healthy snacks like string cheese or apples dipped in carmelYou will feel better about yourself if you make the effort! Good Luck!

- Q:i know this sounds gross but i waited for a while on the toilet but it wasnt coming out! all there was, is this clear liquid coming out of my vagina which i was un sure about so i pulled up my pants and gave up!! D: i think im constipated! please help( im not pregnant!!)

- I'd say Google it and you will find all kinds of dessert pizza recipes BTW.I love pizza and the dessert ones are wonderful!

- Q:Not talking about the patterns but is it okay to knit tightlySome people loosen their yarn when they knit but I kinda have short yarn so is it okay to knit tight without uncomfortable-to-wear result?

- One thing I have learned along the way in knitting is that there are no right or wrong ways to do anything, but there are some guideposts you need to follow to get what you wantThis is YOUR knitting, so if you are getting what you want, then you are doing it the right wayIf you are not happy with the results, something needs to change hereAt first, I knit with a lot of tension (very tightly), and I got thicker and dense, very stiff fabricBut over time, I have loosened up a little, I used larger needles, and I am getting fabric that is more suitable for what I am makingOf course, there are times that I need to knit very firmly for some things, and others are very loose - it all depends on what effect I wantOthers are going to do it a bit differently, but they like what they get, and everyone is happy that wayShort yarn? Do you mean you only have a little of it available? If you want to make your knitting stretch a bit further, I find that you need to use a larger needle (looser tension) and you will get more fabric with the same amount of yarnLarger stitches cover a larger area, with less yarnAgain, it all depends on what you are going to do with that fabricYOU have to decide.

- Q:I need to start eating smarterMore fiber and protein while less fat.I do te exercise part alreadyIm 18, 6 foot and weigh 163lbsSo im not fat, im actually kind of builtBut since this isn't a dating site uld anyone tell me some healthy meal ideas that fit the earlier stated criteria?

- I've baked cookies in a pan beforeIt didn't really effect the cookies much, if at allIf the cookies spread to the edges though, you get a few with flat edges but they all taste the same anyway so who cares if they aren't all perfectly roundI don't mean to sound condescending in any way but they are called baking pans, so they are good for multi-purpose baking.

- Q:two days before my vacation 2 israel from america for 5 months, i found out that i have kidney stones, 5 in my left kidney 3 in my right (2 centimeters small) i went to see my urologist Doctor before i left and she gave me a whole bunch of pills and said i should pee the stones out!!!! ive been in israel now already for omost two months ive finished all the pills, i don't have insurance here so i cant go 2 the doctors!!! i never felt pain anywhere i don't think i peed them out because from what i already found out ur supposed 2 be in pain!!!! im going 2 see a Doctor only in 4 months will i be okay by then in this time? even though i didn't feel pain is there a chance i peed them out already? im just afraid they might get bigger and i might need surgeryone more question i have a urinary infection I PEE ALOT since i cant see a Doctor for pills or something is there anything i can do 2 stop peeing so much food? pills from the pharmacist without a doctors prescription????

- Most of the influential are careless as well as the minority to their situation, as the cross section are concerned with tv land, reality garbage, jerry Springer, Tom Cruise's baby and Katie's career!

- Q:what basement flooring provides the best insulation?

- i have used both.and honestly the CHI is SOOO MUCH BETTER i love it!

- Q:i'm talking about beryllium's stable isotope, Be-9what are it's uses?

- Of all the metals, beryllium has one of the highest melting pointIts modulus of elasticity is approximately 1/3 greater than steelIt is nonmagnetic, resists attack by concentrated nitric acid, is an excellent thermal conductivity and it is highly permeable to X-raysAt a standard temperature and pressure it resists oxidation when exposed to air As an alloying agent in the production of beryllium copperSheets of beryllium foil are used with X-ray detection diagnosticsFor the reproduction of microscopic integrated circuits in the field of X-ray lithographyAs a neutron reflector and moderator in nuclear reactorsIn nuclear weapons to surround the plutonium sphere which reduces the mass of the sphereIn neutron sources where it is mixed with an alpha emmiter like polonium 210, radium 226, or actinium 227In the making of gyroscopes, various computer equipment, watch springs and instruments that requires light-weight, rigidity and dimensional stabilityIt is also required in those applications where an excellent head condutor, with high strength and hardness and with a very high melting point is neededEven it should act as an electrical insulatorOnce used in fluorescent lighting tubes.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Ceramic Fiber Blanket with Low Heat Storage Capacity

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 roll

- Supply Capability:

- 10000000 roll/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords