Ceramic Fiber Blanket with Inorganic - Smoke Free

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 roll

- Supply Capability:

- 10000000 roll/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

General Information of Ceramic Fiber Blanket

l CMAX ceramic fiber blanket is made from high quality Kao-Ling clay, high purity alumina and silica oxides by spun or blown process.

l Ceramic fiber blanket is asbestos free. Double-side needling provides ceramic fiber blanket with great tensile or handing strength for easy installation.

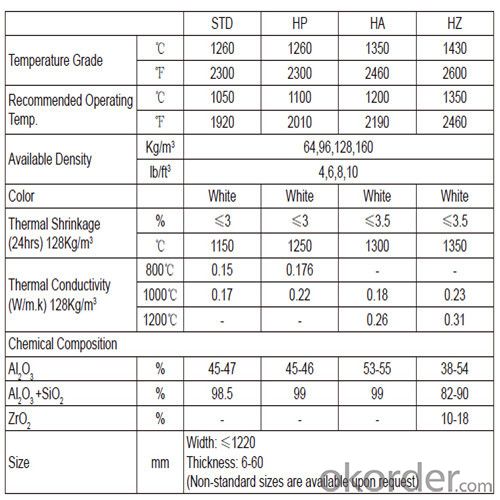

l Ceramic fiber blanket are classified as STD, HP, HA, and HZ respectively corresponding to different maximum service temperature 1000℃, 1100℃, 1200℃ and 1350℃

Image of Ceramic Fiber Blanket

Technical Data of Ceramic Fiber Blanket

Feature of Ceramic Fiber Blanket

Heat resistance

Light weight

Low thermal conductivity

Low heat storage

Resilient to thermal shock

High tensile strength

Application of Ceramic Fiber Blanket

Petrochemical process heater refractory fiber lining

Heat treating furnace or Intermittent (shuttle) kiln hot face lining

General furnace backup insulation

Heat seals for kiln car or furnace door

Electrical insulator

FAQ

Q1: How do you control the products quality?

A1: With strict quality control system throughout the materials selection and production process, our refractory and ceramic fiber products quality is effectively controlled to meet customer requirements.

From the raw materials selecting, our quality control begin. The quality certificates of raw materials are required and each batch will be tested before using. During production, the quality control is conducted by workers and then each piece will be sorted and examined by quality supervisors.

Q2: What`s the lead time for my order?

A2: It depends on customers’ requirements and our production schedule. And usually we need 30-60 days for refractory bricks,10-25 days for unshaped refractory materials and 10-20 days for ceramic fiber blankets.

Q3: Can you offer Door-to-Door delivery?

A3: Yes, but only for some countries such us U.S., UAE, Saudi Arabia, Iran, and Russia, etc.

- Q:I started crocheting about 4 months ago and am still a beginnerI'm finishing up a baby blanket and wanted to know if it's possible to crochet bra? If so can you tell me the pattern and steps to follow, and I would really be grateful if you had a link to a videoThank you!

- Well the flat iron (straight iron) should work well, but if you do it really fast, then you have to do it twice a day, and wash and brush your hair b4 you start.

- Q:The lines on the plaid don't seem to be straight, yet the line up straight with the edges of the fabricI know one side of a pattern piece is straight, but I can't match it to the stripes on the plaidIt's as if the material is stretched wrong or somethingNothing is adding upPlease help.

- If your going to remove the old plaster and the lathYour going to have to replace the old blown in cellulose insulation on all the outside wallsyour going to want to put in a moisture / vapor barrier.

- Q:what's the difference between fibers and textiles?

- well, fibre helps you excrete (poo) and makes sure you dont get constipated! But if you eat too much thenwell it gets runny!

- Q:I am trying to dye clothes that has design on the fabricAlso i have clothes that is white in the inside of the sweater and black on the outsideHow is that possible????

- This saves the rain forest because if every christmas they cut like a 10,000 Christmas trees it affects the environment there will be too much polution if you recicle you can even save money think about it!! The plastic affect because the earth cannot destroy itThe use of less light means less power plants which is good because it causes cancerIf you leave water running we have less water to drink and whenthe water get recycle it is cleanerHOpe i helped im just 15

- Q:I've been searching around for some ribbon and some fringe that will work with my costumeI've already got the bodice made and close to finished beadingWhat I'm looking for is some ribbon for a skirt I'm making out of yellow peach/orange and a silvery green fabricThey're vertical stripes and I'm looking for some ribbon that has those colors and an almost maroon red color to cover up the seamsI'm also looking for most of those colors in a fringe for around the brown overskirt I'm makingI'm just wondering if anyone has some ideas on websites I should check outthanks bye

- I would check first local arts and crafts stores and stores that sell fabric, string, yarns and maybe they may know where to find what you are looking for.

- Q:cuz im working towards a sixpack but overall i want a healthy body im like 70% therei dont drink protein shakes because i want long term results im in no rush.i stay very active skate to work which is like 4 miles awayI lift like 3 times a week work full time its fast food so im constantly movingi just wanna know foods that are high in protein or fiberlist as many as you canbecause cooking is one of my hobbies i need ideasthanks

- well, meats are high in protienLike chicken, fish, steak, etc Pumpkin has high protien and fiberYou can make pumpkin smoothies (which are great tasting) with splenda and strawberries- and you can eat pumpkin seedsCollard greens are high in fiberI eat it with vinegar.

- Q:because I just found out im 12 weeks pregnant and I have to take a drug test either this Saturday or TuesdayThe last time I smoked was November 18

- Works Bomb Chemistry

- Q:I'm replacing my wood garage door (which is attached to my home) with a steel door (because it's cheaper), but I don't know which insulation to useHome Depot offers the board insulation and another company is offering the injected foam insulationWhich one should I use.

- Make Over 200 Juicy, Mouth-Watering Paleo Recipes You've NEVER Seen or Tasted Before?

- Q:i want to know if there's a way to keep them out of landfills.

- You are nice to do soTrust meA hairdresser screwed my hair up when she bleached it and the following day i went and dyed it mild brown, then 2 days later i dyed it dark brownIts now not the best factor i could of achieved however your hairs not goin to fall out since of itIt's going to probarly be relatively dry however simply get a go away in conditioner.

- Q:My cat sucks on blankets.we have given him his own blanket so we are not sleeping in wet sheets.but if i wash his blanket will he still want it? and does anyone know how to stop this behavior?

- my cat does this tooevery time i try to go to sleep, she jumps into bed and starts sucking on the blanket, it's so annoying! she does it to everything though, even after it's been washedso now, when she starts doing it, i tap her on the head or just put my hand between her mouth and the blanket so she can't do itit's worked pretty well, now after a couple minutes of trying she just gives up and goes to sleepgood luck!

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Ceramic Fiber Blanket with Inorganic - Smoke Free

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 roll

- Supply Capability:

- 10000000 roll/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords