Ceramic Fiber Blanket STD Ordinary Fireproof Insulation Blown Process

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 3000 roll

- Supply Capability:

- 100000 roll/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

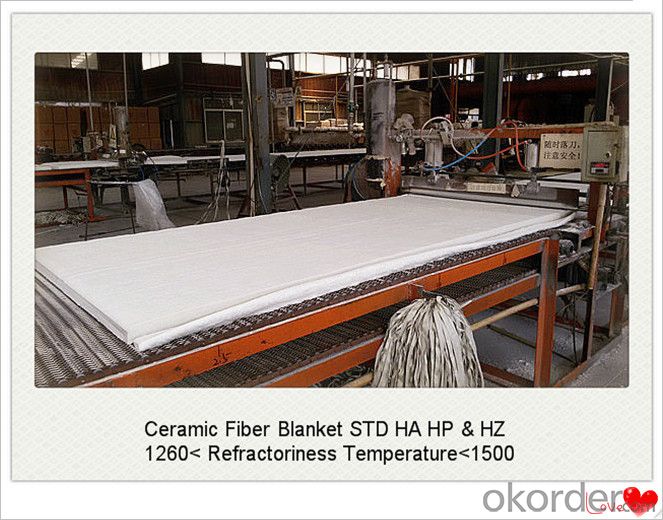

Ceramic Fiber Blanket STD Ordinary Fireproof Insulation Blown Process

Description for Ceramic Fiber Blanket

Ceramic fiber blanket, board and cloth are made from high quality clay, high purity alumina and silica oxides by spun or blown process.

Ceramic fibre blanket, board and cloth have a range of products:ordinary type,standard form,high-purity type, high-alumina type and containing zirconium type.Different types of products used different materials. performance of ceramic fibre insulation blanket also has difference,and they are suitable for different workong temperatures.

Ceramic fibre blanket, board and cloth can be used after optional cutting .When ceramic fibre insulation blanket storage should be paid attention to moistureproof.The high-alumina type and containing zirconium type products can be directly used as furnace lining .And using high-temperature refractory adhesive when stick.

Features for Ceramic Fiber Blanket

1)Low thermal conductivity

2)High tensile strength

3)Resilient to thermal shock

4)Corrosion resistance

5)High-purity type

6)High-temperature refractory

7)Al Content (%): 32-55

8)Type: 1260℃ STD/HP, 1350℃ HA, 1430℃ HZ

9)Density: 64-160kg/m3

10)Size: 12.5×610×14400mm, 25×610×7200mm, 50×610×3600mm

Major Images for Ceramic Fiber Blanket

Packaging and Delivery Images for Ceramic Fiber Blanket

FAQ

Can we accept OEM for Ceramic Fiber Blanket?

YES! We can according your demand to produce.

Can we accept the detective of the third-party verification company ?

YES! We can accept the detective from any third-party verification company including the SGS, BV and so on.

If you have any enquiry,please don't hesitate to contact us, okorder will provide our best products and services for you!!

- Q:i have a down comfortor but the filling is a polyester fiber and the outside is cottoni know to be stingy with detergent, and should i dry it on a low setting?

- I know that cabbage is a big one it will cause gas and cause the baby to be fussy.

- Q:Two weeks ago I had some plumbing done and he was up in the atticHe turned on my attic fan and insulation blew all over the placeJuly 4th I came home and my ceiling was dripping and stainedIt turns out the drain for the condensation was plugged up with insulationIt was working fine before he was up in the atticDid this cause the plugging of the drain? If so I want the plumbing company to repair the damageIs this reasonable? I opened up the ceiling and the drip pan was full of insulation and I vacuumed it out but can not get the drain unplugged.

- so you had a better day than me then

- Q:Why does a fibre glass stove top crack spontaneously? This morning I found the top to be uniformly cracked?

- With all the new wool and and softer, although more expensive yarns out there now, I don't find much use for acrylic yarns now because they can seem stiff and scratchyThey are still good though for fun stuff for the kids like purses and doll clothesI inherited a HUGE tote bag full of it from my mother-in-law, and didn't know what to do with itThen I found out that you can make lap quilts that are 24x36 and donate them to rest homes for the elderly who are in chairs most of the time to keep their legs warm, so that is what I am doing with itI thought that would have made my mother-in-law, who has passed away, very happy to know.

- Q:Should I use 50% alpaca 50% wool or 100% alpaca?If there are pros and cons for both, please let me know!Thanks!

- Buy any coloring product with 'permanent' on the boxleave the color on for at least 25 minutes but probably for the full 45 minutes in your case because of the big shade changefollow the instructions in the box, it's really pretty easy and most are under $5.00 an application now.

- Q:I just had a baby 3wks ago and im braestfeeding and im really constipaded and i wanted to know if i could drink metamucil, I tried stool softeners n they dont seem to help.

- 2 pounds ground beef chuck or sirloin 3/4 cup oatmeal 1 each onion 1/2 cup ketchup 1/4 cup milk 2 large eggs 1 tablespoon horseradish 1 teaspoon salt 1/4 teaspoon black pepper 1/2 cup ketchup 1 tablespoon horseradish 3 tablespoons brown sugar 2 teaspoons prepared mustard Directions Combine first 9 ingredients; shape into two 7 1/2x4 inch loavesPlace on a lightly greased rack of a broiler pan; bake at 350 degrees F for 40 minCombine 1/2 c ketchup, 1 T horseradish and remaining ingredients; spoon over meatloaf and bake an additional 5 minNOTE May freeze the second loaf.

- Q:I will soon be running wire for a heat pump I am having installedI need to run 2 6-gauge thhn, 1 10-gauge thhn wires in a conduit from the panel to where it will be hooked up to the furnaceI have a fair bit of electrical experience just not running something like this before.I'm wondering how this is generally done and have a few questions- What size conduit would be best to accommodate those wires? - Would installation in the attic or crawlspace be better? - If in crawl can i strap the conduit to the bottom for the rafters? Then go up into the rafters to cross a support wall in the center of building?- If in the attic can i run it over the rafters with out issue? and the same go down into the rafters cavity?I can easily install it either in the attic or the crawlspace but was not sure if there normals of how its installedThanks in advance!

- Fiberglass is the bestYou can either go with batts or loose fill, which is blown in14 of loose fill gives you R-38, as does 13 of battsHope this helps.

- Q:i was woundering if you saw a drop of box for your local shelter at your local stores, would you donate? things like leashes, collers, dishes, blankets, exci 'm thinking of doing this, i'm just woundering if it would work?

- I decided to do that too instead of buying themSince you'll need at least 150, (you might want to get a few more so you and your hubby can eat them later that night or the next night while on your honeymoon) buying flats of strawberries will be the best thing to doThe price is really going to depend on where you live and whether the strawberries have to be shipped very far to your local supermarket, but I would think it would only be between $50 to $75 for that many and the chocolateYou can purchase colored cellophane to wrap them in and tie with ribbon matching your wedding colorsCongrats.

- Q:I'm a picky eater and I'd like a high fiber snack idea for work and maybe one for breakfast so I can stay full longer at workI don't like quot;weirdquot; food but I'm open to an suggestions.

- Don't even think about it.

- Q:I would like to learn how sew and knitt my own clothes or just about anything? ?

- I would use acrylic paint I would plan on getting my hands messy but acrylic paint is easy to remove when still wet with soap and waterI might use a brush or just my handsI might place the painted balls on aluminum foil or parchment paper to dry after painting

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Ceramic Fiber Blanket STD Ordinary Fireproof Insulation Blown Process

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 3000 roll

- Supply Capability:

- 100000 roll/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords