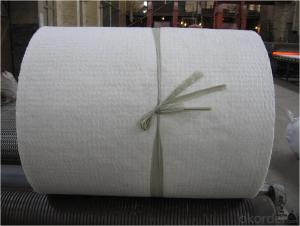

Ceramic Fiber Blanket for Industrial Insulation

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5 roll

- Supply Capability:

- 5000 roll/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Industrial Insulation Ceramic Fiber Blanket

Product Description:

Ceramic fiber paper is made from high quality clay, high purity alumina and silica oxides by spun or blown process. Ceramic fiber has a range of products: ordinary type, standard form, high-purity type, high-alumina type and containing zirconium type. Different types of products use different materials. The performance of ceramic fiber yarn is also different, and they are suitable for different working temperatures.

Ceramic fiber yarn can be used after optional cutting. When storing ceramic fiber, pay attention to moisture. The high-alumina type and containing zirconium type products can be directly used as furnace linings.

Product Features:

• Low thermal conductivity

• High tensile strength

• Resilient to thermal shock

• Corrosion resistance

Product Applications:

• Petrochemical process heater refractory fiber lining

• General furnace backup insulation

• Heat treating furnace or intermittent(shuttle) kiln hot face lining

• Electrical insulator

• Heat seals for kiln car or furnace door

• High temperature acoustic

• Fire protection

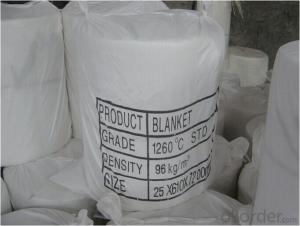

Product Specifications:

Type | STD | HP | HA | HZ | |

Classification Temperature (°C) | 1260 | 1260 | 1350 | 1430 | |

Working Temperature (°C) | 1050 | 1100 | 1200 | 1350 | |

Color | Spotless white | Spotless white | Spotless white | Spotless white | |

Density (Kg/m³) | 64,96, | 64,96, | 64,96, | 64,96, | |

128,160 | 128,160 | 128,160 | 128,160 | ||

Shrinkage at Heat (%) | ≤3 | ≤3 | ≤3.5 | ≤3.5 | |

(24 hours, density at 128/ m³) | (1150°C) | (1250°C) | (1300°C) | (1350°C) | |

Thermal conductivity by temperature (w/m.k) (density at 128kg/m³) | 0.15 (800°C) | 0.176 (800°C) | 0.18 (1000°C) | 0.23 (1000°C) | |

Tensile Strength (kN/m) | 0.04 | 0.04 | 0.04 | 0.04 | |

Chemical | AL₂O₃ | 45 | 46 | 52 | 38-54 |

Composition | AL₂O₃+SIO₂ | 97 | 97 | 97 | 82-90 |

(%) | ZrO₂ | - | - | - | 10-18 |

Product Packing:

Plastic bag in a carton box

Product Images:

FAQ:

Q1: Why buy Materials & Equipment from OKorder.com?

A1: All products offered by OKorder.com are carefully selected from China's most reliable manufacturing enterprises. Through its ISO certifications, OKorder.com adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q3: What other products does OKorder offer?

A3: We offer a full range of refractory bricks, mortar, cement, ceramic fiber products, and more.

Q4: Where are Ceramic Fiber products used?

A4: Ceramic fiber products have many advantages, including: high temperature stability, lightweight, superior insulation, and ease of application. Fiber products are available in a variety of product forms to solve a range of thermal management application problems across various industries. The main industrial market segments that use ceramic fiber and soluble fiber products are the aluminum, iron, steel, heat treatment, power, incineration, boilers, and glass industries.

Q5: What kind of Ceramic Fiber should I use?

A5: When selecting the fiber type for a particular application, it is important to consider all factors. If the fiber/fabric will not have to support a load at temperature, the lower-cost industrial grade fibers may be appropriate. However, if the fiber will be load bearing at temperature as in ceramic matrix composites, then one of the composite grade fibers would be a better choice. Of course there may be other factors, such as corrosion, chemical resistance, or atmospheric conditions that may require trade-off in the selection process.

- Q:I want to finish my basementIt has poured concrete walls and no flooding or moisture I've noticedI've seen stuff about vapor barrior, and spray in insulation, and the roll out fiberglass batt insulationIs there a best for the price insulation, + what about the framing for the drywall after the insulation? Do you frame before or after a spray in insulation?

- Its got to be heroin or meth for sure.

- Q:I have decided I need more fiber in my meals, but anything high in fiber doesn't taste that greatFor example, most cereals that are high in fiber don't have any tasteCan you think of any food or meal plans that are high in fiber but delicious too? Thanks.

- Bran muffins with ginger are so gorgeous.

- Q:these are the questions i have to answer1) explain how the fabric is made2) What is it made from3) Who invented or discovered this fabric4) Was it an accident5) Is it a synthetic or natural fibre6) What are some of fleeces propertys, and qualitys7) explain 4 of these8) are there differences in the quality of this fabric9) what is wicking10) what types of items can be made from this fabric?asi said, i have been sick, and not just not paying attention at schoolIts for textiles, and im in year 9 but trying to get into V.C.E textiles next year(wich is a really hard thing to do) i have been told that my production has been good enough, but to get in i have to get atleast 80 percent on this assigment, if i dont i can just say good bye to my dreams of fashion designingmy teacher is really crabby when students are sick, are will never give out exceptionseven if you can only help answer one of these questions it will be greatly appreciated.

- Because the undergo is sliding down at a regular pace the Net drive have got to be 0Due to this the Force of gravity have got to same to the Force of frictionFgmagazine 230kg(nine.8m/s^two) down 2254 N down Therefore Ff 2254 N up

- Q:I have an outdoor porch with a roof on it, but the concrete gets a little wet when it rainsBoth my 2 yr old and dog love to hang out there and watch the cars go by, so I'd like to crochet a big rag rug for where they sitIs it best to use 100% cotton material cut into 1quot; strips for the quot;yarnquot; - or should I use polyester fleece 1quot; strips instead? Trying to figure out the best material for outdoors that won't get destroyed if it rainsActually I'll be happy if it lasts through this summer/fallOrdo you have some other suggestion?

- They are the same in applicationBoth are trainsIntermodal is a type of train, as is a unit train, as is a manifest, passenger, commute and so onBut in practice, the other trains compete for territoryWhat I mean is, if there is a hot pig in the picture and you are in the last siding in which your whole dog train will fit, you sit, for however long it takes for the pig to get there for the meetOne hour, five hoursdidn't matterAnd in the case of a significantly tardy pig, Amtrak heads in for onceIntermodal is hotGood trains to be onwaiting fornot so muchUltimately, it comes down to, How big is your lunch?

- Q:I just got a hamster a few months ago, I have been keeping my room warm for him, but it is wearing me out because of the heat in my room I am always getting stuffy noses, and bloody nosesI am use to my room being much colder! My room is currently around 72 degrees, how can i make him warmer, but my room a bit colder?

- Rage against the machine is heavy metal mixed with rap which is original and interestingRed hot chili peppers are just rock, really.

- Q:What type of yarn so it will keep it's shape.

- The yarns I like best for hats that keep their shape are Lion Brand Vanna's Choice (100% acrylic), Plymouth Encore (25% wool and 75% acrylic), and Cascade 220 Superwash Wool (100% wool)Red Heart Supersaver (100% acrylic) will definitely keep its shape, although it's more difficult to knit withI'd avoid Simply Soft or anything drapey because it won't keep its shapeIf you live in parts of the country where really cold means in the range of 25°F to 40°F and it seldom snows (where I live), any fiber will do and 100% acrylic will do just fineIf your area gets colder than that and you deal with regular snowfalls, you'd do better to use a yarn that is at least 25% woolWool keeps its warmth even when it's wet, so a hat that's 100% or even 25% wool will do a better job of keeping the heat in even if you're out in the snow.

- Q:a mouse got into my electric range and ate the wiring for the oventhe tech will not fix it until all the feces is gonecan't vacuum it or the insuralation with suck up .

- Its almost impossible to separate mouse dropping from insulation its best just to toss the insulation and put new stuff in if it bothers youPersonally I find mouse droppings are pretty harmless and maybe you should find another repair man who is not so finicky

- Q:Why are high fiber such as fruits, vegetables, and complex carbs considered quot;healthyquot; if they make you crap?

- Throw that junk awayPut the drumsticks on a cookie sheetIf it's an old-fashioned cookie sheet without non-stick coating, line it with aluminum foil and grease the aluminum foilPut the cookie sheet with the naked drumsticks in the oven and turn it to 350 degreesWait one hour and you're finished.

- Q:I have three rabbits, a lop mix, a mini rex, and a mini rex / dwarf mixUp until this year they have always been indoor rabbits, but last July I moved, and had to put the bunnies outside (stupid landlord)They seem to be doing fine, but I'm getting worried because the temperature is dropping really badIt's supposed to be 4 degrees Fahrenheit todayIs that too cold? Is there anything I should do? I don't want them to freezeAlso, I've been giving them fresh water 2-3 times a day, because it freezes so fastIs that often enough? I'm just so worried about them.

- Well, where i live, 2 guys and a pickup doing skilled labour type work (landscape maintenance, garbage hauling, etc) would be about $70-80 per hour.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Ceramic Fiber Blanket for Industrial Insulation

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5 roll

- Supply Capability:

- 5000 roll/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords