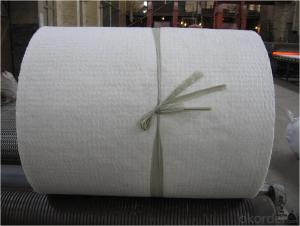

Ceramic Fiber Blanket for Foundry Insulation

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 4 roll

- Supply Capability:

- 5000 roll/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Ceramic Fiber Blanket for Foundry Insulation

Composite of Ceramic Fiber Blanket for Foundry Insulation

Ceramic Fiber Blanket for Foundry Insulation is made from high quality clay, high

purity alumina and silica oxides by spun or blown process.

Types of Ceramic Fiber Blanket for Foundry Insulation: ordinary type, standard form, high-purity type, high-alumina type and containing zirconium type. Different types of products used different materials. Performance of Ceramic Fiber Blanket for Foundry Insulation also has difference, and they are suitable for different working temperatures.

Main Features of the Ceramic Fiber Blanket for Foundry Insulation

◆Low thermal conductivity

◆High tensile strength

◆Resilient to thermal shock

◆Corrosion resistance

Application of Ceramic Fiber Blanket for Foundry Insulation

◆Petrochemical process heater refractory fiber lining

◆General furnace backup insulation

◆Heat treating furnace or intermittent(shuttle) kiln hot face lining

◆Electrical insulator

◆Heat seals for kiln car or furnace door

◆High temperature acoustic

◆Fire protection

Ceramic Fiber Blanket for Foundry Insulation Images

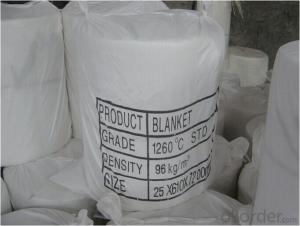

Ceramic Fiber Blanket for Foundry Insulation Specification

Type | STD | HP | HA | HZ | |

Classification Temperature (°C) | 1260 | 1260 | 1350 | 1430 | |

Working Temperature (°C) | 1050 | 1100 | 1200 | 1350 | |

Color | Spotlessly white | spotlessly | spotlessly | spotlessly | |

white | white | white | |||

Density (kg/m3) | 64,96, | 64,96, | 64,96, | 64,96, | |

128,160 | 128,160 | 128,160 | 128,160 | ||

Shrinkage on heating (%) | ≤3 | ≤3 | ≤3.5 | ≤3.5 | |

(24 hours, density as 128/m3) | (1150°C) | (1250°C) | (1300°C) | (1350°C) | |

Thermal conductivity by different temperature (w/m.k) (density as 128kg/m3) | 0.15(800°C) | 0.176(800°C) | 0.18(1000°C) | 0.23(1000°C | |

0.17(1000°C) | 0.22(1000°C) | 0.26(1200°C) | 0.31(1200°C) | ||

Tensile strength (MPa) | 0.04 | 0.04 | 0.04 | 0.04 | |

(density as 128kg/m3) | |||||

Chemical | AL2O3 | 45-47 | 45-46 | 53-55 | 38-54 |

composition | AL2O3+SIO2 | 98.5 | 99 | 99 | 82-90 |

(%) | ZrO2 | - | - | - | 10-18 |

FAQ of Ceramic Fiber Blankt for Foundry Insulation

Q1:Are you a manufacture or trader?

A:Factory+trade(mainly factories,at the same time,we operates other related products).

Q2:Can you offers samples?

A:Of coures,samples are free but freight paid by the buyers.

Q3:What's the MOQ of trial order?

A:No limit,We can offer the best suggestions and solutions according to your condition.

Q4:Is your company accept customization?

A:We have own factory and excellent technical team,and we accept OEM service.

Q5:How about your company's certification?

A:ISO9001 and Test Report,also we could apply other necessary certification.

Q6:How to slove the quality problems?

A:If the products are not confirmed to customer samples or have quality problems,our compay will be responsible to make compensation for it.

Q7:Can you accept OEM for Ceramic Fiber Insulation Roll?

A:YES! We can according your demand to produce.

- Q:When you fire clay, do you actually put it in a fire inside of a special oven ( kiln)? If not, could you ever just put it in a fire ( like making a traditional pizza) and still have good results? Thanks!

- textile is clotha textile mill makes the cloth

- Q:I have wavy, frizzy hair and straighten itHowever, it never looks as good as when the hairdresser does it with the products she uses, not to mention the added damage i get from not using any kind of productWhat kind of products do i need to buy to achieve frizz- free silky straight hair?

- Difficult to say, there are many hotels, inns, stately homes, castles etcin the UK which claim to be hauntedThe older the building, the more likely it is to have a resident ghostUsually someone who died there in violent or suspicious circumstances There are also air bases which are reputedly haunted by the ghosts of men who served there in wartimeOne - I think it's at Duxford, there is a Museum with a Lancaster bomber and people alone in the building at night have heard what sounds like the flight crew doing their final pre-take off checks - instruments, radio etc.

- Q:I am growing my hair long and have bought a straightenerWhat are some good products to help prevent my hair from getting alot of damage from the heat and breaking off?? When my hairdresser straightened it, the results were amazing but I just can't make it look like she did at all! I need some tips on the type of straightener that works well and also some tips on great products to give it body but still help keep it straight! Also wondering if it is ok to straighten hair every day with a straightener??

- There are 2 products that I use that work really well 1Redken-Smooth Down Heat Glide, it protects your hair against the heat and minimizes frizziesYou only have to use 1-2 pumps so it lasts a long time2Herbal Essences-Dangerously StraightAlso when you straighten your hair try not to wash it the next day, with my hair I only can go 2-3 days without washing itWhen you wash your hair everyday it washes out all of the natural oils that keep your healthyI usually can wear my hair down for 2 days straightened and the next day I wear it in a pony tail or bunYou can also add a little bit of baby powder to your hair when it starts to get greasy to take some of the grease and shine outI do this so I'm not damaging my hair everyday with the heatYou can get any ceramic made hair straightener, the ceramic kind is the best protection for your hairYou can probably go to your hair salon and pick up a good straightener and product thereGood Luck!

- Q:Just as what's stated aboveI wanna put letter onto a blanket which spell out my niece's nameI heard that if you have a towel or some other piece of fabric between the blanket and iron, the effects will be all the same?Can I get some tips/pointers, please?

- Aussie is the best hair spray and personally I think Bed Head is the bestI have wavy hair too and my hair just loves it! Amy

- Q:A textile fiber manufacturer is investigating a new drapery yarn, which has a standard deviation of 0.3 kgThe company wishes to test the hypothesis H(0): mu 14 against H(1) mu lt; 14, using a random sample of five specimens.a) Find beta (type 2 error) for the case where the true mean elongation force is 13.5 kg and we assume that type one error 0.05.b) What is the power of this test (from a)now assume n 5c) find the boundary of the critical region if the type 1 error probability is specified to be 0.01d) Fine beta (type 2 error) for the case when the true mean elongation force is 13.5 kge) what is the power of the test now?I keep reading the chapterand i think I get itthen I check my answers and it just rejects them every time gt;.gt; I'm so damn lost

- wow! I took that stuff 12 years agoHeck if I remember how to do itGood luck!

- Q:Hey, I'm a 20 year old guy/ I was under extreme anxiety about a possible combat tour because I am in the military, and other things bothering meHowever, this caused me to become very constipatedI was ordered to take metamucil powdered fiber, and it did not helpSo i was prescribed pills that just made me illThen finally I was prescribed mira-lax which helped some, but not muchThen I bought colon-detox pills which again helped for a short time, but no longer help.Should I buy an OTC enema and give it to myself?

- Are you certain there could be nothing else causing the constipation? If so, discontinue whatever that isIf not, drink more waterIf drinking more water does not provide immediate enough remedy, you could try magnesium citrate laxatives (the little green bottles), although I'm not certain of their efficacy given that the mode of action is similar to miralaxYou won't want to leave the house after ingesting those puppies, btwAlso, I'm not your doctor, so I would not try anything I say, nor can I be held liable if you didPeaceNote, this is for the short termFor the long term I would recommend upping your real non-soluble fiber intake (and keep drinking enough water) to give your stool substanceI'm guessing that if it is stress induced, the problem is also related to under-eatingChill out with some fiber one bars and some cracklin' oat bran, etcProducts that contain chicory root are especially effectatious.

- Q:It is just for one stop along the road but it will be for about one and a half hoursI will make sure she has a warm sweater and a coat and blanketsI expect the temperature to be in the mid 30sThank you

- I'm sure your going to get alot of people saying that your a horrible owner but i say, you got to do what you got to doThey have a coat for a reason and thats to keep them warmI think she will be just fine, just make sure its not too long and make sure she has gone potty.

- Q:My hair is always frizzy,how can I make it not so frizzy and a lot softer looking?:)

- It does not to any extent further than the different gases interior the ambience doextreme tiers of water vapour interior the ambience would point out that the wind is coming off the sea, wherein case, temperatures would be cooler than if the wind comes off the land in summer time however the water vapour itself does not impact the temperature.

- Q:I just learned how to knit recentlyI know that the knitting patterns posted online usually tell you very specifically which size knitting needles and which size yarn you should be using, but I don't want to have to keep buying the exact size recommended for each pattern I want to make, so I was wondering, is there any sort of general rule to figure out which size you should be using? For example, if I'm using very thin yarn, would it be best that I use a very thick needle, or would a thin one be better? .Does it even make that large of a difference which size I use?

- Psyllium seeds or husk is very beneficial for constipation, and is recommended highly in AyurvedaIt has helped me a lotI have a doubt for Stacey thoughPsyllium seeds/husk are cited as a good source of Soluble fiber, which according to the definition of soluble fiber would mean that they do not aid in constipationHowever, the real-life effects are the oppositeIt is one of the best natural diuretic and laxative around, and i am talking from experience!

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Ceramic Fiber Blanket for Foundry Insulation

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 4 roll

- Supply Capability:

- 5000 roll/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords