Ceramic Fiber Blanket for Fire Insulation 96/128 kg/m2

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 kg

- Supply Capability:

- 2000000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Ceramic Fiber Blanket Spun Process Supplier

Ceramic Fibre Blanket is ideal thermal insulation material, fire-proof material and sound-absorbing material. Ceramic fiber blanket has even texture and smooth surface. CNBM ceramic fiber blanket is made of high quality alumina-silicate ceramic fiber by using double side needling methods which improve the tensile strength and the flatness of the ceramic fiber blanket. Our ceramic fiber blanket providing effective solutions to a wide range of thermal management problems. Utilizing our proprietary high output blowing and spinning techniques, these products supply superior insulating performance, flexibility and resilience.

Product Applications:

Ceramic Fiber Blanket are ideal for use in the below applications

Heat treating furnace or intermittent (shuttle) kiln hot face lining

Electrical Insulator

High Temperature Acoustic

Fire protection

Incineration equipment and stack linings

Product Advantages:

Professional manufacturer of ceramic fiber products with more than 12 year experience.

We are one of the manufacturers who can produce ultra-thin blanket.

Our factory equipped with 23 production lines to ensure a timely delivery

Main Product Features:

High tensile strength and low shrinkage

Good resiliency with low heat storage

Low thermal conductivity

Good sound aboption

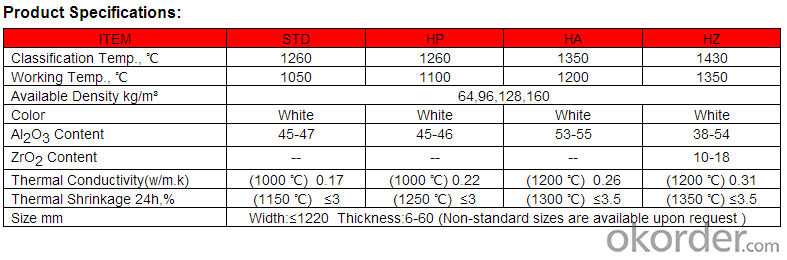

Product Specifications:

FAQ:

Q1: Are you a manufacture or trader?

A: Factory+trade (mainly for manufacturing, also do some business of related products).

Q2: What's the MOQ of trial order?

A: No limit,We can offer the best suggestions and solutions according to your requirements.

Q3: After an order is confirmed,when to deliver?

A: According to your order quantity, normally, 15-25 days after deposit received.

Q4: Is your company accept customization?

A: We have our own factories and excellent technical team, and we accept OEM service.

Q5: What certificates do you have?

A: ISO9001, BV and Test Report, also we can do other necessary certification according to your requirements.

Q6: Can you offer samples?

A: Of course,samples are total free! Freight should be paid by buyers.

Product Picture

- Q:and how much should I eat a day?

- You can use a microwave with foil, some guides give it as a way to stop parts of food being overcookedAn example would be the wings on a chicken while the body has not heated all the way throughUsing an entire bowl though tends to negate the effect of microwavingTo test your microwave put a glass jug with 1 litre of water in it and switch on fullTime it to a boilThere is a formula for the power transfer but basically if your happy its not too long it passesSometimes a microwave will spark for no apparent reason when you do the water test, this is due to food debris ionizingClean it and you're ok againMicrowaves are also good for heating plates, just the plates, so you can serve your oven meal nicely to guestsp/s, Try coring and peeling an apple, fill with custard or jam, heat, some cinnamon or icing sugar if desired, a one minute desert.

- Q:I am making a sweater for my grand daughter that has a horse pattern in itThe instructions are for a size 6 but I need a size 4I tried to cut the number of stitches down but the pattern (tho it fits) takes up to much room on the backI would like to try either a smaller set of needles or a lighter weight of yarnwould this alter the shaping of the sweater?

- It would work for a small difference in size that only needed 1 size needle changeMore than 1 needle size may make the fabric stiffTry knitting a piece in your yarn and see if you life the resultYou would also need to consider whether the proportions need changing at the neck and armholeIt would be better to find a pattern in a finer yarn, to get the extra stitches, and put your horse pattern on the back of that.

- Q:Whats the best wall insulation to use for and existing house that has never had any insulation in them?

- Existing house suggests a couple of things which you left out of details1Is the interior just studs? 2If there is drywall and studs, it might be that even blown in from an attic/crawl space would be blocked by cross bracing between the studs Best is relative, and R values are measured in various forms and materials, IE: 1 inch foam is approxR 3 Some added details might help you get better answersDOC

- Q:WHATS THE BEST WAY TO PUT BLOWN INSIN WALLS WITHOUT DRILLING A TON OF HOLES?

- There's no easy answer to thisOlder homes can have odd and undetectable obstructions in the wall framing, or for two story homes with old balloon framing, the cavity between the wall studs can be open to joist spaces in the floorsWhat this means is that blowing insulation in from any place has risks of stopping at random in the walls, or possibly filling the spaces in the first floor ceilingYour two most common choices are cellulose and foamCellulose is cheaper and easier for the do it yourselfer, but harder to control in the wall cavity and know for sure it's going where you want itFoam is easier, with experience, to control in a wall cavity, but more difficult and expensive for the do it yourselferEither way, unfortunately, the more holes you drill the better your chances of getting a thorough job done.

- Q:I discussed with my doctor my dietary needs and she told me to eat more fiber and more proteinI know about nuts and meats and vegetables, but could someone please give me a nice long list of some tasty options?Ill give you a clue in on my likes and dislikes:i will not eat: fish, seafood of any kind, yogurt, jello, or artichokesI like broccoli, carrots, green beans, peas, beef, chicken, some nuts (peanuts, sunflower seeds) oh yeah and i tried multi grain bread and i almost puked.

- Yeah, did they take a little in a to-go bag? I mean, the damage was done, might as well get some damned fruit out of it.

- Q:Ok so, My parents dont let my bunny on the bed, but I still doNow he PEED ON MY BLANKET! Please let me know how to waash a blanket with bunny pee on it without parents knowing!!! I dont want to yell or hit him to make sure he wont do it again I cant stand seeing him sad so please help!

- Never Fail Pie Crust 4 cups all-purpose flour 2 cups butter flavored shortening 1 tablespoon white sugar 1 teaspoon salt 1/2 cup ice water 1 egg 1 tablespoon distilled white vinegar In a large bowl, mix flour, shortening, sugar and saltAdd ice water, vinegar and eggBeat to combine.

- Q:you know, the ones you put groceries inshes seriously addicted to these bagsshe will lick and try to bite pieces offand its not just a bag from one store, she likes them from anywhereany ideas why she's doing this?

- I enjoyed which you probably did this piecei'm inspired to place in writing as quickly as returnedI get exhilaration from the importance of the rose that grew threw the concrete, referencesuper touchThe 0.33 stanza grew to become into the main suitable for mesturdy lines and visualsAll in all a super attemptTemari

- Q:You know how you put one roll or one piece of insulation between one wall and the other what if you sqeeze in another one? what will happen is it recommended is it discouraged? what about a thicker layer of purple spray insulation? Will it be easy to keep a room cool/warm?

- Iron is used in making steelSo steel wool would be an iron product Copper is used in conductors, so any wiring is copper Aluminum is used to make soda cansNickel is not normally used by itself, but it is used as a coating for many metals, including nickel coated guns and wheelsNickels used to be made of nickel, and are still coated with nickelCarbon is used in tires to make them blackA tire would be light gray and not as strong without the carbon content.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Ceramic Fiber Blanket for Fire Insulation 96/128 kg/m2

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 kg

- Supply Capability:

- 2000000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords