Ceramic Fiber Blanket for Boiler Heat Insulation Bio-soluble

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details for Ceramic Fiber Blanket for Boiler Heat Insulation Bio-soluble

| Grade: | HP (High Pure) | Application: | Refractory | Thickness: | 10-50mm,6-50mm |

| Width: | 610mm 1220mm | Length: | 7200mm | Chemical Composition: | AL2O3+SIO2 |

| Ultimate Strength (≥ MPa): | 0.08-0.12 | Working Temperature: | 1100℃ | Fiber Diameter: | 2-5um,3-5um |

| Shrinkage (1800 ℉, 3h): | -4 | Thermal Conductivity: | 0.09 | Density (kg/m³ ): | 96 |

| Model Number: | 1260 | Brand Name: | Place of Origin: | (Mainland) | |

| Color: | Pure white | Certification: | ISO9001 | Manufacture: | Factory of China |

| Operating temperature: | 1100℃ | Products Name: | bio-soluble ceramic fiber blanket for boiler insulation | Application of ceramic fiber blanket: | boiler insulation |

| Sample: | avilable |

Packaging & Delivery

| Packaging Detail: | PE bag inside,carton box outside,or pp woven bags outside,or according to customers' requirement |

| Delivery Detail: | within 15days after confirm the order |

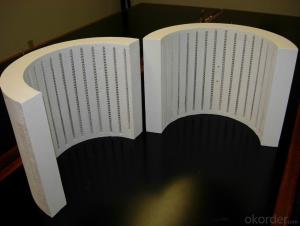

Heat Insulation Bio-soluble Ceramic Fiber Blanket for Boiler Insulation

Product Description

![]()

Description of bio-soluble ceramic fiber blanket:

Technical index of bio-soluble ceramic fiber blanket:

Product Item | ordinary | Standard | high-purity | High Aluminum | Zirconium |

Specification Tem() | 1100 | 1150 | 1260 | 1360 | 1430 |

Classification temperature() | 1100 | 1260 | 1260 | 1360 | 1430 |

Work temperature() | <1000< span=""> | 1050 | 1100 | 1200 | 1350 |

Color | White | Pure white | Pure white | Pure white | Pure white |

Density (kg/m3) | 96 128 | 96 128 | 96 128 | 128 160 | 128 160 |

Permanent linear shrinkage(%)(after24 hours, density 128kg/m3) | -4 (1000) | -3 (1000) | -3 (1100) | -3 (1250) | -3 (1350) |

Thermal conductivity (w/m.k) density 128kg/m3) | 0.09(400) 0.176(800) | 0.09(400) 0.176(800) | 0.09(400) 0.176(800) 0.22(1000) | 0.132(600) 0.22(1000) | 0.76(600) 0.22(1000) |

Tensile strength (Mpa) density128kg/m3) | 0.08-0.12 | 0.08-0.12 | 0.08-0.12 | 0.08-0.12 | 0.08-0.12 |

Classification temperature() | 1100 | 1260 | 1260 | 1360 | 1430 |

Work temperature() | <1000< span=""> | 1050 | 1100 | 1200 | 1350 |

![]()

Application of bio-soluble ceramic fiber blanket:

1. The material of wall lining and back lining of industrial furnace and the sealing and insulation material of expanded gaps of furnace wall, furnace door, furnace top lid, etc.

2. Insulating material of high temperature

3. Excellent materials to produce module and folded module

- Q:Who can help me introduce the principle of vacuum forming of ceramic fiber board? Thank you very much.

- Features: excellent chemical stability, excellent thermal stability, excellent tensile strength, low thermal conductivity, low thermal capacity, excellent sound absorption and noise reduction performance. Typical applications: aerospace, steel, petrochemical high temperature insulation; military road insulation; electrical components insulation; fire protection; high temperature gasket; modules, folding blocks of raw materials. Three. Ceramic fiber felt products: ceramic fiber vacuum forming felt is made of ceramic fiber cotton produced by resistance furnace injection molding. It is processed by vacuum forming process. It is a lightweight, flexible refractory fiber insulation material, made of a combination of high purity refractory oxides and organic binders. In addition to the excellent properties of bulk ceramic fiber cotton, the ceramic fiber vacuum forming felt has good strength and elasticity, and is a versatile product. Product characteristics: high strength, long service life; low heat capacity, low heat conductivity; non brittle material, toughness; size precision, good flatness; cutting easy installation, convenient construction; excellent anti erosion properties; continuous production, fiber distribution, stable performance; excellent acoustic noise performance.

- Q:The product characteristics of ceramic fiber cloth?

- Product characteristics:High temperature resistance, low thermal conductivity, thermal shock resistance and low heat capacity;

- Q:What is the difference between the national standards for ceramic fiber products and ordinary aluminium silicate?

- Ceramic fiber products (aluminum silicate fiber products) in recent years, ceramic fiber products (aluminum silicate fiber products) in the application of high temperature sintering furnace expanding, ceramic fiber products (aluminum silicate fiber products) refractory felt and blanket products, the highest use temperature up to 1649 DEG C. Ceramic fiber products (aluminum silicate fiber products) to heat insulation effect is good, easy to use, especially small heat storage characteristics, widely used in various kilns, greatly demonstrated high energy efficiency. Ceramic fiber products (aluminum silicate fiber products) (1) ceramic fiber products (aluminum silicate fiber products) varieties and properties of ceramic fiber products (aluminum silicate fiber products) is the most important indicator of fiber diameter and thermal stability. Al2O3SiO2 fiber is commonly used in ceramic industry. It is divided into different application range according to the content of Al2O3, and Cr2O3 material is introduced into it to improve its refractory and oxidation resistance.

- Q:Brief introduction of ceramic fiber cloth

- - Product Description -Ceramic fiber cloth is made of heat-resistant gold wire or non alkali glass yarn reinforced spun wire ceramic fiber yarn. The ceramic fiber cloth has high strength, good flexibility and processability. It not only has high temperature insulation property, but also has the flexibility of ordinary textile. Fire retardant clothing, fire blankets, insulation and other industrial and civilian fire insulation products.- Product Categories -Fiberglass reinforced ceramic fiber clothHLGX-208A1 (glass yarn reinforced)Wire reinforced ceramic fiber clothHLGX-208A2 (heat resistant stainless steel wire reinforced)- product characteristics -Good high temperature tensile strengthGood electrical insulation performance? good acid, oil, water vapor corrosion resistanceLow thermal conductivityGood insulation performanceNo asbestos, non-toxic and harmless, no adverse effects on the environment- typical applications -Equipment, instruments, high temperature protection, removable insulation, apply raw materialsThermal insulation and thermal radiation shielding of high temperature pipes and containersIndustrial furnace door sealing, large equipment insulation gasketIron and steel industry continuous casting and rolling fire curtain curtain? fire shutter, labor protection clothing, fire protection clothing, household and commercial fire fighting blanketCable or fuel line protectionHigh temperature resistant metal compensator, refractory layer, soft connection of high temperature pipeline- technical indicators -Ceramic fiber clothClassification temperature (DEG) 1260Product code HLGX-208A1 HLGX-208A2Use temperature (DEG) 6501000Basic material: ceramic fiber / glass fiber reinforced ceramic fiber / wire reinforcedThe theory of volume density (kg/m 500 + 15 fand)Regular size (mm) 30000 * 1000/2200 * 2/3Moisture content (%) = 2The meridional density is 56 ~ 60piece/10cmThe zonal density is 24 to 30piece/10cmCauterant (%) = 15Plastic bag, outer woven bag

- Q:What kind of material is ceramic fiber? What are the basic performance?

- Ceramic fiber, referred to as "ceramic fiber felt", is a kind of high temperature resistant refractory material (such as precious stones) by arc melting, compressed air sprayed with a fibrous material, also known as "ceramic fiber cotton.". Using ceramic fiber cotton, it can be made into all kinds of ceramic fiber products. The content of domestic ceramic fiber felt from AI2O3 is 62% and 45%, the former is 1150-2000 DEG C, and the latter is l000 DEG C.The ceramic fiber felt by the adhesive is divided into hard ceramic fiber felt (aluminum phosphate adhesive), ceramic fiber felt soft (adhesive latex, polymerization aluminum, water glass, methyl cellulose, latex 11 aluminum phosphate composite adhesive) and ceramic fiber wet felt (adhesive silica sol) three. According to the performance of the felt and the temperature of the furnace, the hot surface of the furnace wall can be made of hard felt.The size of the ceramic fiber product is 600 * 400 * 20 (10) mmThe basic properties of the felt are as follows:(L) the use of high temperature can reach l000 degrees centigrade.

- Q:How to choose the right ceramic fiber and aluminum silicate products?

- 3, according to the thickness of insulation to chooseThere are a lot of insulation thickness of furnace is fixed, the insulation thickness of conventional material is inappropriate, only according to the heat flow calculation formula to calculate the appropriate level of insulation material is the most scientific, the conventional case raised to two of the product can be registered.

- Q:What is ceramic fiber?

- 1, ceramic fiber is a fibrous lightweight refractory material, has the advantages of light weight, high temperature resistance, good thermal stability, low thermal conductivity, specific heat and resistance to mechanical vibration, and thus in machinery, metallurgy, petroleum, ceramics, glass, electronics and other industries have been widely used.2, ceramic fiber products is a good refractory. The utility model has the advantages of light weight, high temperature resistance, small heat capacity, good insulation and heat insulation performance, good high-temperature heat insulation performance, no toxicity, etc..3, light quality, good heat insulation performance, good thermal stability, good chemical stability, easy processing and convenient construction. It is neither wear-resistant nor collision resistant, can not resist the erosion of high-speed airflow, and can not resist the erosion of molten slag.

- Q:What is the process of producing ceramic fiber mats?

- 3) good high temperature strength and heat insulation performance (refer to physical and chemical indexes).4) having a higher level of electrical insulation and high temperature electrical insulation than glass fibers.5) non-toxic, harmless and odorless.

- Q:What brand of ceramic fiber products is best?

- The quality of the above products can be highlighted from two aspects:1, large-scale production2, the application of advanced technology3, brand awareness of the high and low

- Q:What is the customs code for ceramic fiber products?

- The customs code should be 6914.9000Specific can be seen by the Chinese customs published in 2005 edition of import and export commodity names and codes, thirteenth and sixty-ninth chapters, ceramic products, P166-168 pages.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Ceramic Fiber Blanket for Boiler Heat Insulation Bio-soluble

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords