Ceramic Fiber Blanket 2400 2" x 24"8# Dens

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 2000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

General Information of Ceramic Fiber Blanket

l CMAX ceramic fiber blanket is made from high quality Kao-Ling clay, high purity alumina and silica oxides by spun or blown process.

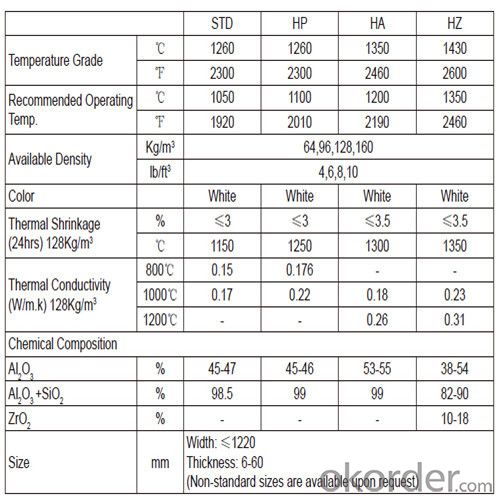

l Ceramic fiber blanket are classified as STD, HP, HA, and HZ respectively corresponding to different maximum service temperature 1000℃, 1100℃, 1200℃ and 1350℃

l Ceramic fiber blanket is asbestos free. Double-side needling provides ceramic fiber blanket with great tensile or handing strength for easy installation.

Feature of Ceramic Fiber Blanket

Heat resistance

Light weight

Low thermal conductivity

Application of Ceramic Fiber Blanket

Petrochemical process heater refractory fiber lining

Heat treating furnace or Intermittent (shuttle) kiln hot face lining

General furnace backup insulation

Image of Ceramic Fiber Blanket

Technical Data of Ceramic Fiber Blanket

Why Choose Us

l We are a government owned company with ISO certificate.

l We have more than 11 refractory production facilities and bases across China. We have a wide products range, such as ceramic fiber products (ceramic fiber blanket, module, board, paper, bulk), ceramic fiber textile (ceramic fiber rope, cloth, tape, yarn) etc, refractory brick (fireclay brick, high alumina brick, silica brick, magnesia brick etc), monolithic refractory materials, insulating fire brick.You can find various products here, and we can combine the light weight ceramic fiber products with the heavy weight refractory brick in one container delivery, then save the sea freight for you.

FAQ

Q1: How do you control the products quality?

A1: With strict quality control system throughout the materials selection and production process, our refractory and ceramic fiber products quality is effectively controlled to meet customer requirements.

- Q:Hey, I'm Korean ; 5'2 ; Female ; 108 Pounds ; Freshman after this coming summerSo this is my diet exercise plan over summer break/vacation from school (early planning)June 30 to August 31Right when I wake up:1/2 of a Caffeine Pill1 Fish Oil Pill1 One Day Women Pill2 Gummy VitaminsBreakfast: Benefiber mixed into low fat yogurtLunch: 2 Slimfast or Weightloss (from Costco) DrinksDinner: NormalWith familyUsually meat, rice, seaweed, some type of soup2 laxativesSnacks:VitaminsFiber In YogurtLaxativesHot Green TeaExerciseWallSits for 2 Minutes50 Push Ups3 Miles Every SundayPlus it's during summer time so I OF COURSE will be riding my bike, swimming, runningONE QUESTION:I have these indents like an apostrophe or comma (' ,) at my cheekslike the apples of my faceare they fat? cause some of the fittesthealthiest people have itbut to me, it just looks like my face is fatthanks for answering you guys:)

- I don't see what his being white has to do with the question197 is not large for a man of 5-11I don't see why you care so much about what sounds like 8 or 9 lbsMaybe you feel jealous that he can gain weight and no one notices?

- Q:Every time I eat or drink anything now it runs through meI have diarrhea so badI go at least 10 times a day on a normal dayIt contains alot of mucusSometimes it's bright yellow and oilyI have went from a pant size 17 to below a 12 in 3 weeksI am scared something might really be wrongI already know I have IBSBut it's getting worse by the dayI still eat and I eat healthy so I won't get weak or dehydratedBut It does not matter what I do it still happensWhat could this be from besides IBS?

- Go to your doctorNowWeight loss is NOT a sympton of IBS, there's definitely something serious going onYou're going to get very dehydratedUntil then, avoid the common triggers: AlcoholArtificial sweeteners or sugar substitutesArtificial fat (Olestra)Carbonated beveragesCoconut milkCoffee (even decaffeinated)DairyEgg yolksFried FoodsOilsPoultry skin and dark meatRed meatShorteningSolid ChocolateTry to include lots of soluble fiber, from foods like: BarleyBrown riceCurrantsDried beansFigsFrench breadFresh peasMethylcellulose (Citrucel)Oat BranOatmealPastaPrunesPsyllium husks (Metamucil)RaisinsRiceSourdough breadSoy.

- Q:Everyone at the barn where I board has a different answerSome say to blanket in the 30's, some say to wait till 20's.others say don't do it at allI'm trying to stay as close to the way nature intended for my horses in all aspects, but this is one of the ways I'm a little on the fence aboutWhat temp does everyone blanket (or not), what about wind, snow, etc? Also, what about stalling? I have stalls, but I want to do what makes the horses happyPersonally, if I were a horse, I wouldn't want to be cooped up in a stall all the time.

- Ah, yes, wonderful Wisconsin, the wonderful state that brought us Jeffrey Dahmer and Ed GeinMaybe it's something in the cheeseDespite the occasional oddaball, it's actually a pretty decent state, home of many fine people such as myself(blush blush) By the way, did you read a couple of weeks ago about the fellow who fell into a vat of chocolate in Milwaukee?

- Q:How is it made? And if you're a hardcore vegan, do you approve?

- without some form of cloth used for a parachute air cannot be trapped people would drop like a torpedo

- Q:Hi,I just started a transitional life style change of getting rid of all processed foods and only eating clean food especially a lot of fruits and vegtablesI just recently made my first green drink made completely out of vegtablesTo my heartbreak (I really thought I was doing my body good) my stool came out dark green and really hard to pass/dryI did some research and found out that its normal if you start increasing your intake of green vegtables and iron which I have been doingIt also said that the body is rejecting the overdose of fiber and nutrients that it cannot use (extra)Does this mean I should stop drinking green drinks for good? I really want my body to be healthy and not depend so much on meatAny advice for continuing?

- Not aluminum foil, but they do have crock pot liners that are sort of plasticJust bought some the other day.

- Q:So I don't own too many clothes as a guy, but it really annoys me when my shirts fade, get holes, thin, deform, and shrinkI'm going to get new clothes soon, and I don't want them to mess up like all my other clothesI wash shirts after I wear them once, and rarely wear them multiple times without washing because they smellAnd a lot of my hoodies eventually look like they were played with a dog.the fabric appears more rough and warn outHelp?

- At the top of the window of your Internet browser, click on the view option, then go to text size, and increase font from there.

- Q:Is fibre glass amorphous?What atoms is it made up of?I have done so much research just cant find anything for fibre glass, no atomic structure no crystal structure.

- If the kittens are different sex, then they probably want a different box, since the girl kitties don't generally like to share a box with the boy kitties as their urine becomes more muskyGet them both fixed (altered), and get them both their own litter box.

- Q:i've been experimenting with many diets lately, and high fiber foods seem very beneficial but i'm wondering what the deal with prunes iscalorie limitation seems good too, but it's much more difficult

- Prunes are actually high in fiber, but it's the Sorbitol (sugar) that helps loosens the bowels.

- Q:Don't ask questions just answer ; DMy yarn is acrylic red heart, and I need it to get as matted as possibleI want it to stick together and be super tangled and fuzzy, like big strands of dreadlocks.

- Godless or godfilled world, someone will always take it to the extremeSomeone will always take scripture literally .and people will never changeIt'll always be a race to see who can do what and who did it betterWho's richer, happier, whatever the case may be Just remember a World full of God is always a world ffilled with SatanYou can't have one without the other.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Ceramic Fiber Blanket 2400 2" x 24"8# Dens

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 2000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords