Ceramic Fiber Blanket 2300℉, 3600*610*50mm, 96 Bulk Density

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 200 kg

- Supply Capability:

- 5000000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

General Information of Ceramic Fiber Blanket

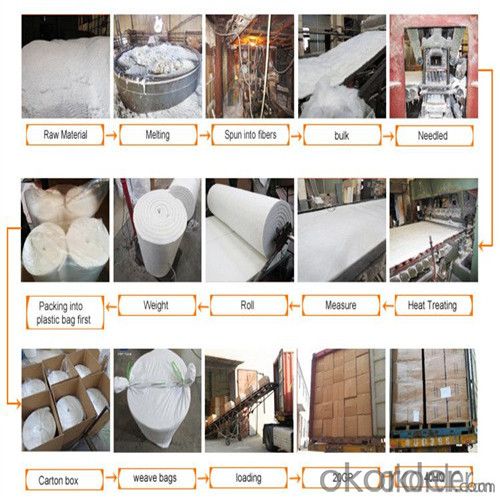

l Ceramic fiber blanket is a needled blanket that is made from high purity spun ceramic fiber, suitable for high temperature insulation up to 2300°F.

l CMAX ceramic fiber blanket is made from high quality Kao-Ling clay, high purity alumina and silica oxides by spun or blown process.

l Ceramic fiber blanket is asbestos free. Double-side needling provides ceramic fiber blanket with great tensile or handing strength for easy installation.

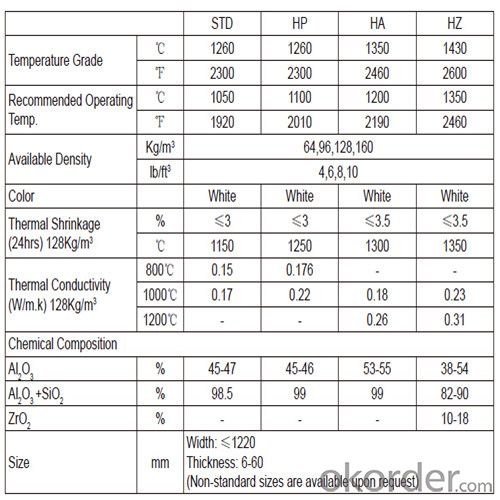

Product Sizes and Variants of Ceramic Fiber Blanket

Width: ≤1220mm

Thickness: 6-60mm

Density: 4, 6, 8 lbs./cu. ft. (64, 96, 128 kg/m3)

(Non-standard sizes are available upon request)

Also available with aluminum foil back

Customer Application Notes

Product Handling: Require protective gloves, cloth, mask and dust control.

Characteristics of Ceramic Fiber Blanket

Lightweight

Low thermal conductivity

High temperature stability

Excellent handling strength

Low heat storage

Thermal shock resistance

Chemical and corrosion resistance (commonly used acid and alkali)

Excellent fire protection

Application of Ceramic Fiber Blanket

Petrochemical process heater refractory fiber lining

Heat treating furnace or Intermittent (shuttle) kiln hot face lining

General furnace backup insulation

Heat seals for kiln car or furnace door

Electrical insulator

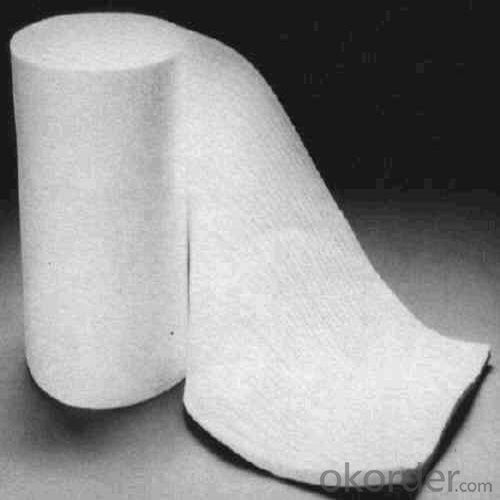

Image of Ceramic Fiber Blanket

Technical Data of Ceramic Fiber Blanket

Who We Are

OKorder is offering high quality Ceramic Fiber Blanket at great prices with worldwide shipping. Our supplier is a world-class manufacturer of ceramic fiber products, with our products utilized the world over. OKorder annually supplies a full range of products to European, North American and Asian markets. We provide quotations within 24 hours of receiving an inquiry and guarantee competitive prices.

Why Choose Us

We are a government owned company with ISO certificate.

We are listed in Global Fortune 500 with D & B report.

We have more than 11 refractory production facilities and bases across China. We have a wide products range, such as ceramic fiber products (ceramic fiber blanket, module, board, paper, bulk), ceramic fiber textile (ceramic fiber rope, cloth, tape, yarn) etc, refractory brick (fireclay brick, high alumina brick, silica brick, magnesia brick etc), monolithic refractory materials, insulating fire brick, calcium silicate board, mica sheet, steel fiber. You can find various products here, and we can combine the light weight ceramic fiber products with the heavy weight refractory brick in one container delivery, then save the sea freight for you.

We have strict materials selecting system and quality control system. We have the ability to take responsibility for your orders and product quality.

FAQ

Q1: Why buy Materials & Equipment from OKorder.com?

A1: All products offered by OKorder.com are carefully selected from China's most reliable manufacturing enterprises. Through its ISO certifications, OKorder.com adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q3: What other products does OKorder offer?

A3: We offer a full range of refractory bricks, monolithic material, ceramic fiber products, and more.

Q4: If I need your offer, what information do you need?

A4: In order to choose suitable products, it will be appreciated to provide us the information, such us specification, technical data, order quantity, products application etc.

If any question, please contact us freely.

- Q:I heard that if a rabbit chews on a blanket, then they could die because of the blanket fibers that get stuck in their stomachWell, my rabbit chewed a big hole the shape of a circle about 2.5 inches in diameter in my blanket, and I'm afraid she might die or something! Will there be anything wrong?

- Well, to tell you the truthI had two rabbits beforeOne of them had to be put down :'( because he got a blockage on his stomachI am pretty sure he chewed on a towel he found.snif.sniffI have the other rabbit left and he has chewed onto fabric before :-S (they find their way to get to stuff) and he is okI think it depends on the rabbit itselfSome rabbits have a more delicate digestive systemI would take him to the vet is he doesn't go to the bathroom or eat in 12-24 hoursDon't wait more than that if he is not doing those two things .Don't worry, he will probably be okFeed him more hay :)

- Q:i want to weigh 20lbs less.i am 4'10 -16yr- 130lbsi have quite a bit on leg and arm muscle but i have cellulite on my thighs and tummy fat tooi want to tone and lose not gain muscle.what is the best way to do so?what types of foods should i eat?i go to school from 6am to 2pm mon-friandthen i have practice 4days a week from 2:30pm until 4pmand then 1day i have an extra hour of practice.and 1 day is game day.i am a HORRIBLE runner but am thinking of starting to run on saturday morningshow can i do it well if i am really bad at it?i really want to be thinner and look betteri didnt realize how bad i looked until i saw myself in a picture.also what are some good homecooked/easy/one person meals for dinner? my parents are sometimes too busy to cook so we end up eating out and i am going to either cook dinner for myself or result in not eating dinner.thanks in advance :)

- You are going to have to arrive earlier and do it there as there is no way it will stay warm for 1 1/2 hours and 20 minutes will not heat it enough You cook ham to 145 F internal temp I would tell your sister to expect an early arrival and do it all thereThe only other alternative would be to microwave each portion to tempOf course ham tastes as good cold as it does warm as long as that is what people expect.

- Q:Is Insulation for home is good idea? which company is best for this purpose?

- carry a cooler stocked with three bottles of water a six pack four pb js two oranges a bag of tortilla chips and 12 servings of cool cucumber salsa go to womenshealthmag allrecipes com for the recipe for 22 minutes

- Q:Please, no general answersSpecifically, tell me the names of some vegetables containing a high percentage of fiber and also, tell me exactly how to cook them easily as I'm a student and I can't afford a lot of time or money.

- That is not an illegal bribeYou need to grow up.

- Q:which car is better Maruti dzire topend diesel or i20 diesel?considering a diesel vehicle either Maruti sift dezire ZDI or top end i20 dieselwhich one should be better in terms of over all quality, comfort, space, maintainability, re-sale value after 3 years.

- If you have no insulation in your attic, it will make a considerable differenceDepending on where you live, the insulation companies in your area will know exactly how many inches to put in to achieve an appropriate R valueThere are several different kinds of insulation and even some natural fiber insulation as wellIt is quick and easy to blow in insulation with equipment you can rent from home depot.

- Q:I am trying to knit a pillow using the basic knit stitchThe only thing is that I don't know how to attach my two square pieces together that I knittedCan I run all the edges under a sewing machine like if I was making a pillow out of fabric? The needle I used to sew the squares is 10 1/2I am very new to knitting and don't know much!

- Of course, you have made a piece of fabric, and you can sew fabric togetherFirst of all, you should block your piecesThat is, pin them out to size, and then either (a) mist them, and let dry (b) steam with an iron, but don't press them (c) wash them and then pin out to dryYou want the pieces to be both the same sizeThen, like all fabric, you pin them with RIGHT sides together, and sew with needle and thread by hand, with a stitch catching first one fabric, and then the other, and then back againDon't pull the yarn too tight, but make it firm so there isn't any slack in the yarnMake them neat and fairly close together so you don't have any spaces showingA machine doesn't work too well, since the two fabrics may be too thick, or you don't catch all the stitchesIt just looks better if you use a stitch by hand, with the same yarn you used in the knittingUse a large darning needle, with the blunt pointIt may take some time, but you put all the work into it this far, a few more minutes won't hurtBy doing the finishing really well, you will have put the final touch to make it something to be proud ofTake your time, do it rightWhen you have three sides done, and a bit of the fourth, turn it inside out, and stuff the pillow with a form, or stuffingThen finish that last side, and enjoy!!

- Q:I have a 5 bedroom house and the downstairs part of my house always stays cool throughout the day;however the upstairs part of my house doesn't cool off until midnight or later and it's getting very uncomfortable to everyoneWhat can I do?

- Henry's roof cement make it dry and dirt free and have fun that well seal it.

- Q:My builders blocked up a doorway with plasterboard and cellotex insulation behindThe wall was plastered and then tiled to form part of the showerA year on, the tiles are coming away from the wall.On investigating i found the plaster and plaster board to be soaking wet and the cellotex appears to be sweatingWould i be better to remove it all and fill the space with ordinary fibre glass?

- nuts,oat meal, beans,wheat.

- Q:so i saw a house today, and it does not have an attic, so my question is, Does having an attic save money? because if you have an attic the insulation helps maintain the temperature of your home, so if you don't have an attic, does it cost more to cool and heat your homeThanks

- fire up the grillsteaks are easysalt pepper, light oil each sidehigh heat 3 min each side give or take

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Ceramic Fiber Blanket 2300℉, 3600*610*50mm, 96 Bulk Density

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 200 kg

- Supply Capability:

- 5000000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords