Ceiling Grid Components Lightgage Steel Joist

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10000 pc

- Supply Capability:

- 300000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Brief Description

We are a manufacturer of steel keel with well-equipped testing equipment and strong technical force.

With a wide range, good quality, reasonable prices and stylish designs, our products are extensively used in decoration and other industries.

Our products are widely recognized and trusted by users and can meet continuously developing economic and social needs.

We welcome new and old customers from all walks of life to contact us for future business relationships and achieving mutual success!

Advantages and features:

1.Light,good strength,cauterization resistance and water resistance;

2.Matching magnesium fire-proof board,gypsum board,and many other wall and ceiling board;

3.Moisture -proof,shock-resistance,high-effecient,environmentally-friendly and so on;

4.Easy and fast for installation,time-saving;

5.prompt delivery,high quality,competitive price and complete sets of style;

6.We can supply you the products based on your specific requirements;

3.Image

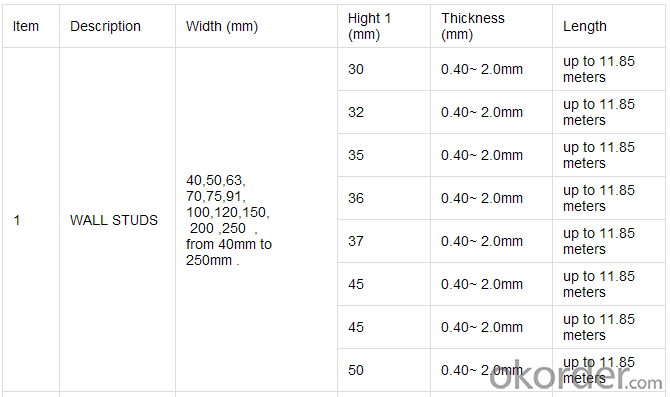

4.Detailed Specification

5.FAQ

functions

1. light weight, high intension, waterproof, earthquake-resistance, dustproof, sound isolation, sound absorption, constant temperature,etc.

2. short time construction peiod and convenient and simple construction.

Lightgage steel joist for ceiling system

1.Material:hot dip galvanized steel

2.Surface treatment: roll coated

3.Application: ceiling grid system

4.Zinc content: 60-140g per sq.m.

- Q:Ceiling light steel keel 50/60 in 60 on behalf of what

- 60 represents the width of the main and vice keel,

- Q:Light steel keel ceiling and wood keel ceiling What is the difference between ah! Which performance is better, the price difference is different! Ask everyone!

- The difference between them is a light steel dragon skeleton. Fire performance is strong. Is a flame retardant material. But in the just equipment is not easy to correct. But the tooling class is not demanding. So it is the best choice .. the future is not easy to deformation .. General For the decoration of the tooling category, the public place when the decoration is light steel keel, wood keel, then fire on the .. wood keel mostly used in home decoration,

- Q:Integrated ceiling and ordinary and wood keel ceiling difference and good or bad?

- Integrated ceiling is a combination of decorative and practical multi-function ceiling. Ceiling keel, integrated ceiling accessories, is a play on the role of supporting the entire ceiling plate accessories. In general, the ceiling keel is divided into light steel keel, wood keel, aluminum keel and so on. Distinguish between the ceiling with a wooden keel good or light steel keel good

- Q:Light steel keel gypsum board ceiling, the main bone the most side of a row, that is, the nearest row from the wall, and the spacing between the walls of what is the rule, if not, is not also by the distance between the main bone 900 -1200MM, gypsum board fixed on the side of the keel on the line. What are the rules for the keel?

- If you use the gypsum board is 600 × 600 specifications, the wall with a glue stick a corner, the main bone spacing is 600MM.

- Q:Light steel keel ceiling good or wood keel good? Residential. I want to use light steel keel, but the designer said the reasons for modeling, light steel

- Light steel keel bearing capacity larger, generally used for public buildings, your house with wooden keel more suitable.

- Q:Light steel keel ceiling one square meter how much money

- 1, installed boom When the floor is a prefabricated board, the hoisting hooks of the suspension boom are embedded in the slit, as long as the upper end of the boom can be bent through the hook hole. When the floor is a cast-in-place plate, it should first release the position of the embedded parts at the bottom of the floor. Use the nail to fix the embedded parts to the bottom of the floor, and bend the upper ends of the boom through the rings of the embedded parts Can be. 2, loaded big keel The large keel vertical hanging pieces, such as a number of sets of dog keel, the big keel handed up, so that the lower end of the boom into the large keel vertical hanging pieces on the hole, plus nuts initially screwed. According to the ceiling of the room in the cave from the arch height (generally take the room to ask the short span of 2: 0), calculate the big keel hanging point at the arch value, twist the nut so that the big keel arch arch, after adjustment , The big keel vertical hanging pieces fastened. 3, installed keel Will be in the keel vertical hanging pieces, such as the number on the big keel, the dragon handed up, so that the keel buckle in the vertical hanging parts of the keel. If the keel intersects with the brace, the keel is placed on the middle keel and the cross brace is in the middle of the keel. Light steel keel ceiling price and construction steps on the finished, you all understand it? For light steel keel ceiling price you can according to their own needs to buy.

- Q:Light steel keel ceiling material calculation method?

- Sheet 300 * 300 = 0.09 / square each 300 * 600 = 0.18 / square each 300 * 250 = 0.075 / square each corners of the per square 2.5 ~ 3 m main keel per square 1.1 ~ 1.3 m reprovision 4 main Hanging sub-keel 3.2 to 3.4 meters per square reprovision three sub-hanging hanging screw 10 square with 3 with a 3-meter screw with 4 expansion head General screw according to the height of the space to set

- Q:Is this a ceiling that can be built? Use light steel keel gypsum board or wood keel? Trouble in detail under the construction process

- With light steel keel backing, after the order made with gypsum board! Grille Ceilings I feel better!

- Q:Light steel keel ceiling effect is what

- Improve the indoor environment conditions, to meet the requirements of the use of functions. Light steel keel ceiling decoration can improve the indoor light environment, thermal environment and sound environment. On the creation of indoor art environment and improve the comfort of the provision of the Pieces. Such as the room in the ceiling under the ceiling, by blocking the air to reduce the impact of the sound, you can improve the indoor sound environment; ceiling space laying insulation, insulation materials, or the use of ceiling space to form a ventilation layer, Thermal environment; light steel keel ceiling shape and color, texture, etc. can adjust the indoor light, can improve the indoor light environment. 2, beautify the space environment, improve the effect of interior decoration Pavilion decoration is more easy to be noticed, it is from the type of space, light, light, color and material, and many other aspects of rendering the environment, contrast the atmosphere, so the roof design should consider the technology and art Combined to achieve finished decorative effect. 3, adjust the volume and shape of the indoor space When the structure of the building structure surrounded by the formation of space is not ideal, the ceiling can be coordinated, unified indoor space volume and shape, enhance the integrity of the ceiling. Concealed equipment pipelines and structures Components can be used within the ceiling space to install lighting, air conditioning, ventilation, sound, fire and other equipment needed pipeline, modern buildings more and more equipment pipeline generally need to be hidden in the ceiling to make the indoor ceiling Clean and tidy.

- Q:Now home decoration, the original ceiling with light steel keel. Now began to install, decoration company said light steel keel will be relatively thick, there will be a sense of oppression, to be replaced by wood keel. Will you heroes this is based on it?

- You did not specify your home that the ceiling is the number of "thickness" - should be said that the upper and lower height, here can only tell you, light steel keel ceiling minimum height of 15 cm. That is, if the bottom of the ceiling, to the bottom of the floor between the distance of 15 cm or more, do light steel keel ceiling is possible. Your home that the ceiling should not be 15 cm are not it? With light steel keel to do the ceiling, compared with the use of wood keel to do, relatively more trouble, because the small size, coupled with the possibility of modeling and other reasons, the decoration company may be reluctant to use it. However, the use of light steel keel to do the ceiling, in the prevention of deformation of the ceiling, gypsum board surface cracking, etc., than the wooden keel to do the ceiling is much better. So, if the distance is no problem, ask them to use light steel keel to do the ceiling as well

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Ceiling Grid Components Lightgage Steel Joist

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10000 pc

- Supply Capability:

- 300000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords