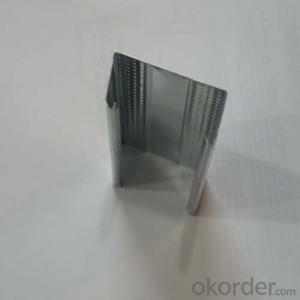

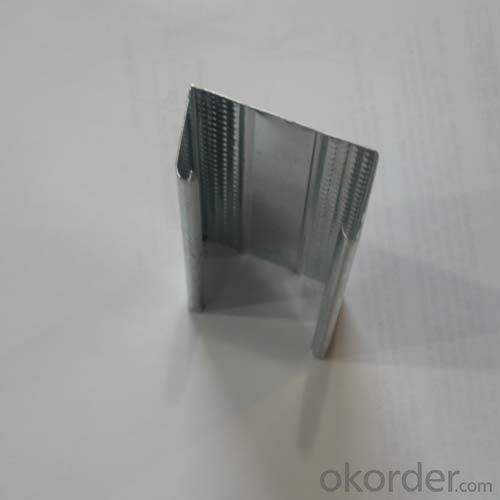

Ceiling Drywall and Gypsum Metal Stud and Track Profile Sizes

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 pc

- Supply Capability:

- 3000000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description:

1.Superposition joint part between main carrier and vice carrier or vice carrier and carrier is called point lap.

2.It uses lap structure to assembly, connection between joints dovetail very well. The joint face unknits and have a nice appearance.

3.There is a barb at the vice carrier joint, it can avoid loosing and falling from the infection of outside force.

4.Soleplate of main and vice carrier is zincification armor plate, which meets the national GB standard demand. We use baked paint zincifcation armor plate as baked paint panel,whoes capacity of zincification is high. It meet the national GB standard demand.

5. Raw Meterial is galvanized steel with 80-100g/sqm

Specification:

Specification for middle east:

Main Channel | 38x12 mm |

Furring Channel | 68x35x22 mm |

Wall angle | 25x25 mm |

C stud | 50x35 mm |

C Stud | 70x35 mm |

C stud | 75x35 mm |

U track | 52x25 mm |

U track | 72x25 mm |

U track | 75x25 mm |

Specification to Australia:

top cross rail | 25x21x0.75 mm |

25x21x0.75 mm | |

Furring Channel | 28x38x0.55 mm |

16x38x0.55 mm | |

Furring Channel track | 28x20x30x0.55 mm |

16x20x30x0.55 mm | |

Stud | 64x33.5x35.5 mm |

76x33.5x35.5x0.55 mm | |

Stud | 92x33.5x35.5x0.55 mm |

150x33.5x35.5x0.55 mm | |

Track | 51x32x32, 64x32x32x0.55 mm |

76x32x32x0.55 mm | |

Track | 92x32x32x0.55 mm |

Specification to Europe, Russia, UKrain, Georgia. etc

C Stud | 60x27 mm |

U track | 28x27 mm |

C stud | 50x50 mm |

C stud | 75x50 mm |

C stud | 100x50 mm |

U track | 50x40mm |

U track | 75x40 mm |

U track | 100x40 mm |

Product Overviews

Advantage and feature:

1.Light, good strength, cauterization resistance and water resistance

2.Matching magnesium fire-proof board, gypsum board and many other walll and ceiling board

3.Moisture-proof, shock-resistance, environment-friendly and so on.

4.Easy and fast for install, time-saving

5.High quality, competitive price and complete sets of style

6.We can supply you the products based on your specific requirements

FAQ

1.Sample: small sample can be offered by free

2.OEM: OEM is accepted

3.MOQ: small order is ok

4.Test: any third party is accepted to test

5.Factory: Can visit factory any time

6.Delivery Time: small order is within 7days or according to your order

- Q:Light steel keel partitions and finished partitions

- Finished partition, generally used in business office buildings, factory production, on-site installation, at one go without any construction in the field to do the operation, removable, removable heavy equipment.

- Q:Light steel keel partition wall construction process is what

- (1) Pin line, sub-file: in the partition with the upper and lower and the two sides of the matrix at the junction, should be the width of the keel line. Battle clear, accurate location. According to the design requirements, combined with the cover panel of the long and wide sub-file to determine the vertical keel; transverse and additional keel position. (2) for the pillow: when the design requirements, according to the design requirements for the concrete pillow. For the pillow should be supporting mold, bean stone concrete should be pound dense. (3) fixed along the edge, along the keel; along the line position fixed along the edge, along the keel, can be fixed with nails or expansion bolts, fixed point spacing should not be greater than 600mm, keel docking should remain straight.

- Q:What is the relationship between the base board and the liner, whether the keel is between the two layers? Such as light in the wall to do soft package, the basic board and liner how to connect?

- In fact, the soft bag is not soft package, sponge package in a 9mm Austrian Song board, this is the soft bag, and then in order to fixed on the wall, in the light steel keel wall to do a lining you said, That is, I mentioned above the blockboard base.

- Q:Light steel keel wall gypsum board seams how to deal with? Including smallpox

- First with gypsum slit smooth, and then paste the old white leather paste with kraft paper, as long as the joints have to deal with. Better than the kind of gauze belt. My family used

- Q:PVC plastic buckle the corners of the corner is how fixed to the wall of the buckle is how and cords connected to the light steel keel and gypsum do cut off the light steel keel is how and the wall surface and ceiling how fixed

- Each corners above the U-slot, this is the use of the buckle board. Light steel keel sub-station dragon and Wolong. Wolong before the installation of the first hammer with a hammer, playing wooden needle, and Wolong fixed, and then install the station dragon, and clamp with a good fit.

- Q:Light steel keel + gypsum board wall and other wall joints how to strengthen?

- Are generally used to deal with the patch to prevent the brush at the brushing of latex paint, keel and wall connection more than a few nail fixed

- Q:4 m long prefabricated board can do light steel keel double gypsum board wall?

- Can be light steel keel wall itself is not heavy weight

- Q:What is the decoration of the wall? Lightweight bricks Or light steel keel frame?

- Decorate the wood keel can be, and then use the integrated wall covered up on it. The other keels are too much trouble and time.

- Q:Curved gypsum board wall technology.

- The curvature of the gypsum board can not be bent directly into the required curvature; if slightly larger, you can spray a small amount of water or water bend into; and then a large curvature of the keel to be encrypted, with plaster slab splicing, and then putty leveling on the line.

- Q:Do the decoration of the brethren, I would like to ask: inside the plant to do light steel keel ceiling, partition (are ordinary), package the price of how much?

- Now the fee is relatively high, but their own buying and too much trouble

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Ceiling Drywall and Gypsum Metal Stud and Track Profile Sizes

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 pc

- Supply Capability:

- 3000000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords