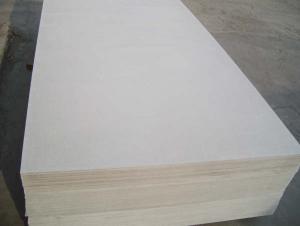

CE standard durable in use waterproof fiber cement board

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

CE standard durable in use waterproof fiber cement board

General Introduction

Terasun CE standard durable in use waterproof fiber cement board is known as TSM---Terasun Silicate Magnesium board. Using foam particles, cement, plant fiber, glass fiber cloth, non-woven fabrics, etc as raw material, Terasun Silicate Magnesium board is made through gelling, pressing and other special techniques and is a new type material renonwn for stability in performance.

Terasun upgraded waterproof fiber cement board---TSM, is characteristic of fireproof, waterproof, high intensity, thermal and sound insulation, long endurance in use, low shrinkage and convenient for construction.

Terasun upgraded waterproof fiber cement board---TSM, is your best choice for buiding, construction and decoration.

Technical Data

| Commodity | Terasun Magnesium Board---TSM |

| Raw Material | Foam particles, cement, plant fiber, glass fiber cloth, non-woven fabrics, etc |

| Density | ≤ 0.95 g/cm³ |

| Size | 1220*2440mm or 1200*2400mm Customerization is available |

| Thickness | 6~20mm |

| Moisture Content | ≤ 8% |

| Fire Rating Test | SGS Class A1 incombustible |

| Moisture Movement | ≤0.12% |

| Bending Strength | ≥ 8.5 Mpa |

| Maximum Service Temperature | 1200 °C |

| Water Permeability | No water vapor after 24 hours' test |

| Refractoriness | 4H |

| Color | Grey |

| Features / Merits | Waterproof; fireproof; termite proof; light-wight; flexional; easily to be shaped, perforated, bended; long service life; environmental friendly, etc |

| Applications | Interior&exterior wall board; fiber cement board; ceiling; free access floor; desktop board; sandwich panel; kitchen and bath wall board; decoration, etc |

| Terasun upgraded waterproof fiber cement board---TSM especially suits to grand ceiling, exterior&interior wall projects of office, conference room, hotel, hospital, plant, lab, commercial center hall, tunnel, subway, airport, warehouse, etc. | |

- Q:Wardboard thickness is about how much

- Wardboard thickness of the need to reach 18 mm, the thickness of the best plate up to 25 mm, which is like building a house had to bear the same wall, the structure is reasonable to build a solid and stable house.

- Q:Oude Sen board in the end where environmental protection?

- Distinguished authenticity: So far, the OKorder market only Knight, strong, Qu Mei, Oriental Parkson, Green Island, the five brands using the German Oude Sen plate. If there are other brands also known as the use of Oude Sen plate, are counterfeit.

- Q:How to do the corn stalks

- Process Technology Line: 1. Straw density plate: Air dry straw → impurity removal → cut off → wind selection (blown out of the heart) → cans → high pressure steam → spray → fine → spray → drying → pavement → preload → hot pressing → edge → cutting → packaging → finished product 2. Straw crushed plate (particleboard) Drying Straw → Cutting → Wind Selection → Recovering → Drying → Screening → (Surface Layer, Dust, Core Material) → Mixing → Pavement → Preloading → Hot Press → Edge → Cutting → Inspection → Packaging 3. Straw composite board Straw → Cutting → Steam Blasting → Mixing → Paving → Wood Veneer → Glue → Preloading, Hot Press → Side → Varnish → Sanding → Finished 4. New wall materials: Corn stover high grain straw → election → leaves → cut → pavement → irrigation → do the surface layer → veneer → sanding → finished In addition to the above processing, the straw can also be used for pulp making after steam blasting, which is about a third less expensive than traditional pulping methods and only one third of the traditional method. It is helpful to solve the problem of pulp gap caused by the forced cessation of small papermaking by the state. Fourth, the main technical key and expected to achieve the technical and economic indicators: 1. Main technical key: ① developed as low as possible, environmentally friendly, waterproof superior, infiltration of a good name of the glue. ② design and improvement of grading pavement. ③ steam blasting equipment selection and the determination of the main process parameters. ④ hot pressing and cold pressing process parameters adjustment. 2. Expected technical and economic indicators: ① adhesive; solid content: 60% -65% ??????????Free formaldehyde content: 0.2% or less ??????????Viscosity: coated with 4 cups: 30 ℃ 10-20 seconds (fiberboard) ?????????????????????????????????50-65 seconds (particle board)

- Q:Black box plate glasses for what kind of person

- If the election is more affinity Recommend the kind of color plate Black is the main color, in the edge of the box through the other colors Bright pink and bright blue are good But also a little round of the black box Not the kind of side (some formal) Or when to pick the time to see There is the kind of wrapping a little more upset That kind of wear will be very cute

- Q:The normal size of the solid wood board

- Long 243.84 cm wide 121.92 cm from the British standard 8 feet long 4 feet wide.

- Q:Always said that the plate is very complex, think about learning a little professional knowledge

- Can be distinguished by the following steps and methods: First is "see", but also to see the focus. Good plate surface smooth and smooth, the edge of the board is very clear. As well as the packaging on the plate is clear, the above name, address, grade, specifications and other information are complete, not clear, incomplete information or more attention to the plate, and may be added to the color of the plate. Two smell, because the legendary formaldehyde is released from the plate, will directly affect people's health. Good plate not only good choice of materials, but also for the adhesive glue is environmentally friendly, even if the number of more stacked together, it will not emit a very pungent taste. If the choice of a plate placed in the home there is a very obvious pungent chemical smell, it should be noted. ?Three saws, before the purchase can be a small sample to the business, and then cut it to see its inner core, a good plate section level is very clear, because it is a layer of paste a very tight, very good convergence, and those miscellaneous Wood stitching the poor quality of the plate core is not dense, must not buy. Four test, through the relevant identification agencies, with professional tools and related technical means to identify the plate to determine the quality of good or bad, this method is more professional and accurate. Plate material is also an important factor is the moisture content, the general moisture content of the plate should be less than 16%, if too high that is not good, may be a while will be mildew or deformation.

- Q:What is the following three pieces of plate, the kind of plate how good. Every time you draw the PCB issued to proofing, I only said to CEM-1, what do not know anything, just graduated from the white is poor, ask the boss he did not say, as if I know, he did not eat The same, I can not directly contact the manufacturers. It 's better to be able to elaborate on the sheet problem

- The first is a ceramic material, the second is halogen-free bar, the third is commonly used FR-4. Because the plate production field a lot, I can only give the industry argument, please adopt or ask me

- Q:Stainless steel wire drawing board, polishing plate, mirror the difference between the three

- Stainless steel wire drawing refers to: stainless steel wire drawing is a stainless steel surface like a filamentous texture, this is just a stainless steel processing technology. The surface is matte, carefully look at the top of a trace of a trace of texture, but can not touch out than the general bright stainless steel wear, looks more on the grade of some. Drawing process will be to a certain extent, the loss of stainless steel plate thickness, generally 0.1 ~ 0.2mm. In addition, because the human body, especially the palm of the hand has a relatively strong oil and sweat secretion, stainless steel wire drawing board often touch will leave a more obvious fingerprints, need to regularly scrub. Stainless steel polishing plate refers to: stainless steel polishing plate is polished by polished stainless steel bright plate, this kind of polishing board is generally not high brightness, but also according to the blurred figure. Stainless steel mirror panel refers to: stainless steel mirror panel industry, said the dual 8K plate, also known as mirror panels, grinding fluid through the polishing equipment in the stainless steel plate surface polishing, so that the brightness of the mirror as clear as the mirror. Stainless steel mirror panel from the K number generally: 6K 8K 10K 12K these kinds. From the requirements of the coefficient points are: the general grinding 8K high Pu 8K ordinary grinding 8K fine grinding 8K ultra-fine grinding 8K these types, of course, are getting better and better. Uses: mainly used in building decoration, elevator decoration, industrial decoration, decoration and other stainless steel products. From the difference, the stainless steel wire drawing board is a long strip of lines covered with stainless steel plate. While the polishing plate is cast into a certain brightness of the stainless steel plate. And stainless steel mirror panels, can be collectively referred to as glass-like stainless steel mirror panels.

- Q:Fu Han plate Malacca and fir lob which is good

- Jinhan, Fu Han are more famous in Hubei local plate brand Malacca, spruce is only representative of the use of raw materials such sheet Like what material can be based on personal preferences, fir to be more expensive

- Q:Now a lot of furniture on the market, do not know the solid wood or wood imitation of the wood

- First of all, you can distinguish from the pattern, pure solid wood furniture pattern is no change in the law, and paste leather furniture pattern changes are very regular, such as butterfly-like, or words continue to head, and pure solid wood furniture patterns are irregular The second measure is that you can look at the furniture is not used to start the falcons, falcons are solid wood furniture, one of the necessary technology, the so-called falcon, that is, slot, wood and wood convergence is not glue and nails , But rather like a child to play the same building blocks, so that together, this is why the reasons for environmental protection of solid wood furniture, and the layout of the furniture is absolutely impossible to use frying craft third trick, generally better solid wood furniture, in addition to In addition to the structure of the falcon, there should be splicing technology, splicing is divided into two kinds, tooth and then flat, as the name suggests, tooth connection, is the two selected wood, both ends are playing like a tooth-like teeth, and then two pairs Together, this is the tooth connection, if there are teeth of the furniture, take the wardrobe door, the door inside and outside the tooth interface must be on the fourth move, solid wood furniture should generally be round circle The design of the corner, because only the wood, in order to withstand the pressure to cut into a circular, the layout is not possible

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

CE standard durable in use waterproof fiber cement board

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords