Cdte thin film solar cell solar panel certificated

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 watt

- Supply Capability:

- 8300000 watt/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Cdte thin film solar cell solar panel certificated

Description:

CdTe is a compound semiconductor material composed of tellurium and cadmium elements. The core material of CdTe power generation glass module is composed of CdTe and CDs compound.The cost of CdTe thin film solar cell module is much better than that of crystalline silicon and other materials in industrial scale.It has been widely used in many areas now.

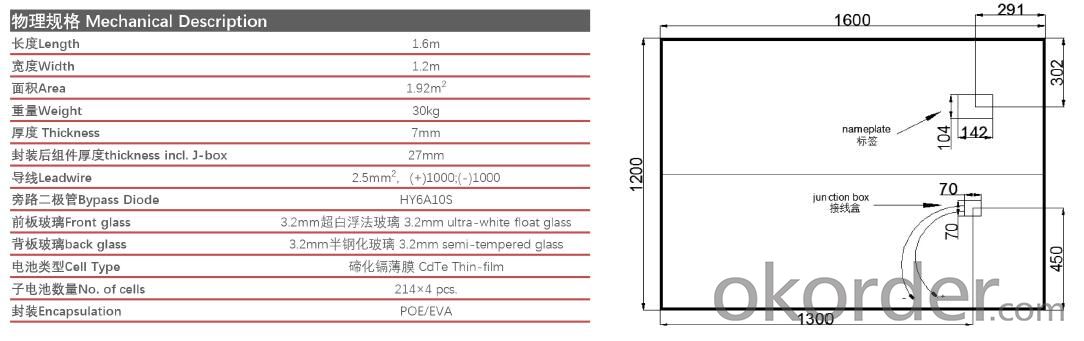

Specification:

Warranty:

Product Features:

•Better spectral response than silicon solar module;

•Superior temperature coefficient:greater energy yield in typical field operating temperature;

•Reduced soiling &better snow-shedding;

•True-tracking advantage;

•Beautiful and perfect for BIPV/BAPV;

Application:

BIPV /BAPV PV Bus STATION PV Plant

Our Qualification:

CNBM Group is a state owned Fortune 500 company.We will serve you the best and ensure you the quality and warranty.

Certifications&Tests:

IEC/EN 61215-2/61730/61646;

DIN V VDE 0126-3,DIN V VDE 0126-5;

Safety class II;

Conforms to :ULC/ORD-C1703-1;

2400Pa-5400Pa Mechanical load-bearing capacity;

Repeated tests on the Electrical parameters and insulation properties during manufacturing;

Tested by independent recognized institutions

- Q:What is the difference between screen printing glass and glazed glass? The What is the difference between product performance, production methods, what is the difference

- Generally speaking, most of the silk screen glass refers to the glaze glass, such as car glass around the black flowers, as well as architectural glass of various colors or ribbons. Architectural glass up to fake glaze glass is the paint glass, the main difference between the two main performance in the firmness - color glaze can not be scraped with a blade, paint can; color glaze never change color, paint will change, and even peeling off.

- Q:Automotive glass insulation film paste technology

- The most basic tools are roasted guns, watering cans, foil special agent (or detergent water), water scraper, paste scraper, deerskin, Huju, a knife, each model is not the same paste method is not the same , But there is a common point of glass must be cleaned, preferably in the clean film between the operation.

- Q:Curtain wall classification of building curtain wall

- (Double beam curtain) component of the wall of the pillars (or beams) first installed in the main structure of the building, and then install the beams (the main structure of the structure, Or columns), columns and beams to form the grid, the panel material in the factory processing into the unit components, and then fixed in the column and beam composed of the grid. The load on the panel material unit component is transmitted to the main structure through the column (or beam). Component-type curtain wall is divided into: the frame of the curtain wall: metal frame components exposed to the outer surface of the panel frame support curtain wall. Hidden frame curtain wall: metal frame components are not exposed to the outer surface of the panel frame support curtain wall. Semi-concealed curtain wall: The vertical or horizontal members of the metal frame are exposed to the curtain wall of the outer surface of the panel.

- Q:I am making a stained glass panel with a lighthouse in it and I want to put windows and doors in the lighthouse. Do I cut them out somehow or put something over the glass

- First the negative bits:- An outdoor wedding would save lighting but risks bad weather and also some guests may not be able to hear well if there is any wind. The set-up costs of this also have to be taken into account and may well be more expensive and create more vehicle emissions than a church or hall wedding venue. Transport is the main emitter of un-green pollution which is under the control of individuals, followed by un-necessary lighting (e.g. upward facing floodlights that mainly light the bottom of clouds). For example: It's very sweet to have a wedding on a tropical beach or a Carribean island; but the CO2 emissions (as well as the cost) of getting everyone there is obscene. If you have to shuttle the wedding party between venues then hiring a bus would be ok. It would also make parking easier at the reception - but where would the guests leave their cars at the wedding venue? Would they be safe? Also, what about those who want to leave at different times? There's always some who don't want (or can't) wait around to the end of the festivities. Now the positive bits:- It would be a Green decision if you had the sites adjacent or in easy walking distance of each other. It's not everyone's cup of tea, but to go green why not have the wedding in a venue local to where the majority of the guests live. You could try asking the bridesmaids to use second-hand dresses instead of having specially made gowns. This isn't as mean as it seems - it's eliminating waste on the production and materials for clothes that would otherwise only be worn once ( the bride's dress is the natural exception). Best of all to go Green would be not to fly anywhere for your honeymoon. If you're travelling beyond a hundred miles then go by train (the greenest of all transport except for a bicycle). Try spending your wedding night in a railway sleeper compartment. That could actually be extremely romantic (James Bond always makes it seem so) and the train crew will make a big fuss of you.

- Q:I would like to build my own, customized aquarium and I have recently found out that float glass would be the best glass to use for it.I want the tank to be pretty long, considering i am turning it into a vivarium for my turtle.I need to know how much it will cost me to buy the sheets of float glass? or If I can just use regular glass for this instead?I am looking for something inexpensive, but with the quality also.thanks for the help :)

- I have only once heard this term (float glass) used before. That was at the Wheaton Arts Museum which was a glass center in the 19th century. The docent was explaining how the molten glass was poured over a layer of molten tin to make flat sheets for window pane. It's commonly called plate glass. Quite frankly you can get a much better answer by calling a glass shop and giving the dimensions. They will give you a quote. But I hazard to say that it will be cheaper to simply buy an aquarium tank. You should note however that if you do build this tank and ever think about filling it with water you really need to consider the stress on the glass. Long panels will collapse under the pressure unless they are very thick or reinforced. You will find reinforcements on the tops of commercial aquariums with long sides. I know a guy who cut the plastic reinforcement because it got in the way of the filter and it didn't collapse until he got it completely set up fish and all.

- Q:Tempered glass and ordinary glass technology and raw materials What is the difference in detail Thank you

- The production process of the glass is: raw material crushing, sieving, weighing, mixing, high temperature (1600 degrees) melting into glass liquid, glass liquid homogenization cooling forming, cutting, annealing, cooling, inspection, packaging. The main raw materials are: quartz sand or sandstone, feldspar, soda ash, limestone, dolomite, in addition to soda ash are ore raw materials, need to break into the appropriate size. Tempered glass is a reusable product of ordinary glass. The main components of its glass is silica, calcium oxide and sodium oxide, so called sodium silicate glass. There are two ways to temper glass, physical steel (air-cooled steel) and chemical steel. Tempered glass is used in the chemical steel method. The principle is to use the "head" of the larger potassium ions to replace the glass surface "head" smaller sodium ions, making the glass surface was tensioned, that is, the formation of compressive stress, so that the glass has a very high impact resistance Increased by 5 times). Physical tempered architectural glass also makes the glass surface compressive.

- Q:China insulation film which company is better? Is it really effective?

- Must have some, after the home posted at noon obviously did not feel so hot, is the China Wu Zhuo glass film company posted

- Q:What are the advantages of building a house entirely made of glass?(Any Type Of Glass)

- 1. You don't have to wonder who is coming up the driveway. You can see anyone. 2. You will learn to be careful- very careful. 3. There is an insulation quality to glass. 4. You can really throw a fit, if you feel like it. 5. You can easily destroy the structure to put up something more reasonable.

- Q:What are the types and specifications of the glass? And how to identify the quality of the glass?

- General glass classification by material, such as: quartz glass, soda-lime glass, etc .; according to the thickness of the points, such as: 2mm5mm10mm, etc .; according to the use of points, such as: architectural glass, automotive glass, a variety of classification

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Cdte thin film solar cell solar panel certificated

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 watt

- Supply Capability:

- 8300000 watt/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords