CC EP NN CONVEYOR BELTS

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m

- Supply Capability:

- 10000 m/month

- Option:

- CC EP NN

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Item specifice

EP:

NN

CC:

CONVEYOR BELTS

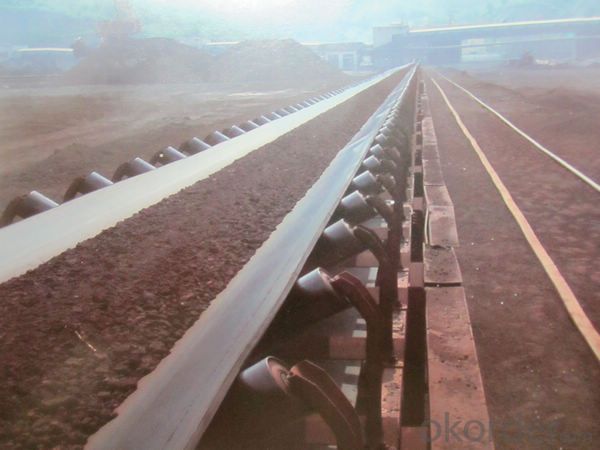

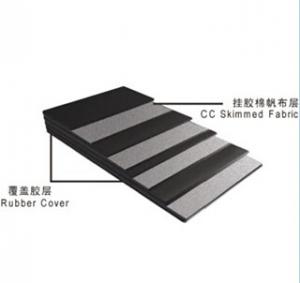

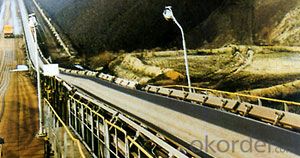

| Application General conveyor belt is widely used in the metallurgy, building materials, electric power, port, Cement, Fertilizer,mineral mountain, agriculature, etc. Which is suitable for transporting normal temperature non-corrosiveness bulk, granular, powder supplies in general conditions. Features 1.Natural rubber Thin belt body with high strength, light weight; 2.Anti-abrasive, impact resistant, corrosion resistant; 3.Softy belt body, good flexibility, excellent trough; |

|

| 1.Physical and mechanical property of cover layer: |

Property level of cover layer | Tensile strength≥ | Tensile yield≥ | Abrasion value≤ |

Mpa | % | mm3 | |

H | 24.0 | 450 | 120 |

D | 18.0 | 400 | 100 |

L | 15.0 | 350 | 200 |

| 2.Tensile property of through thickness: a. The longitudinal tensile strength is not lower than the following nominal value: 160 200 250 315 400 b. The through thickness elongation rate of the belt should not less than elongation rate of trough thickness of the belt should no more than 4%, c. Straightness: no more than 25mm. d. plunger bond stength: |

Index description | Strength between layers≥ | Cover layer and fabric layer | |

Thickness of cover layer≤1.5mm | Thickness of cover layer >1.5mm | ||

Sample average value | 3.2N/mm | 2.1N/mm | 2.7N/mm |

|  |

- Q:What's the difference between a rubber belt and a polyurethane belt?

- The strength and elasticity of rubber are betterPolyurethane is more flexible and less prone to deformation! The weight is comparatively lightThe plant's line is good with polyurethane!If it is a mine or coal or similar mineral, use rubber as a good point

- Q:What sectors does rubber drive? That is to say, what are the main uses of rubber?

- Rubber seal (automobile, mechanical seal (seal), doors and windows), raincoat, rain boots, high temperature Aerospace insulation film, latex gloves, condoms, car tires. Conveyor belt (ore, iron). Rubber floor tiles and so on. Life, industry, everything!

- Q:How should the rubber strap be cleaned and maintained?

- In the water carefully cleaning before cleaning the surface of the watch strap, watch strap, then clean the watchband slot in the dirt. After the band is cleaned, there must be no gloss. It can be painted with silicone oil, so that the strap will be renewed again.

- Q:Where can I buy 3mm thick rubber belts, black ones? Best to explain the price per square meter

- If it's PVC, it might be cheaper. Just 250 or less. What level of view?. A good point on the expensive, rubber conveyor belt, it may be more expensive.

- Q:How do I remove traces on the rubber band?

- Do not use friction products cleaning, easy to scratch strap, you can use a neutral cleansing lotion try, if there is no professional syrup, neutral cleansing milk can also be.

- Q:Why are the engines almost all rubber belts?

- All kinds of driving methods have their own advantages and disadvantages.Sprocket, chain drive - transfer speed is limited.Gear transmission --- the transmission distance is limited and the noise is great.Belt drive - smooth transmission, quiet, easy to implement, low cost.

- Q:White rubber strap dirty, how to do?

- Then wash the back of the strap and clean the surface first. Next, clean the stains in the gap.Finally clean the strap with clean water. The procedures are completed, the rest of the things is to put the watchband in shady place to dry, do not pay attention to sun, will damage the quality of watchband.

- Q:What should I pay attention to when the belt conveyor is setting the brake?

- The transportation is the core mechanical braking torque during the braking process, not only with the main parameters of belt conveyer system, and dynamic load time of braking system, brake temperature rise, the factors related to braking nylon and rubber belt does not slip conditions, the braking torque in the braking process is a process, generally speaking. In the process of braking, the braking torque is not fixed;

- Q:What are the advantages of natural rubber?

- Natural rubber (abbreviation: NR, English Name: Natural Rubber)Usually smoked rubber, crepe, dry glue, glue... Etc.. The dry glue without smoke and natural rubber, color to dry shallow, suitable for light and color productsThe macromolecular structure unit of natural rubber is isoprene, and the macromolecular chain is mainly composed of CIS -1, 4 polyisoprene. NR is one of the best synthetic properties of all rubber in mechanical and processability.

- Q:How about white rubber strap yellowing?

- The white rubber band is yellow and rubbed with the weld polish. Remember, the ratio is 1 to 70.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

CC EP NN CONVEYOR BELTS

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m

- Supply Capability:

- 10000 m/month

- Option:

- CC EP NN

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

New products

Hot products

Related keywords