CC Aluminium Sheet As Per ASTM B 209M - 06

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

1. Structure of CC Aluminium Sheet As Per ASTM B 209M - 06

CC Aluminium Sheet As Per ASTM B 209M - 06 is one semi-finished aluminium material. The alloy AA1050 is widly used in building, industry ect. Its weight is much lower than steel. So many customers choosed aluminium material instead of steel.

2. Specification of CC Aluminium Sheet As Per ASTM B 209M - 06

CC Aluminium Sheet As Per ASTM B 209M - 06 | |

Main Specification | |

Alloy | AA1xxx (AA1050, AA1060, AA1070, AA1100 etc.) |

AA3xxx (AA3003, AA3004, AA3005, AA3105 etc.) | |

AA5xxx, AA6XXX (AA5052,AA5083, AA5754, AA6061, AA6062 etc.) | |

AA8xxx(AA8011, AA8006 etc.) | |

Temper | H14,H16, H18, H22, H24, H26, H32,O/F, T4, T6, T651 |

Thickmess | 0.01mm-100mm |

Width | 30mm-1700mm |

Standard | GB/T 3880-2006/ASTM |

Special specification is available on customer's requirement | |

3. Application of CC Aluminium Sheet As Per ASTM B 209M - 06

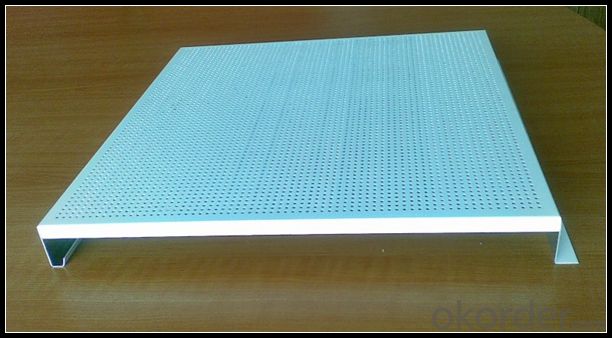

(1).Interior: wall cladding, ceilings, bathrooms, kitchens and balconies, shutters, doors...

(2).Exterior: wall cladding, facades, roofing, canopies, tunnels,column covers , renovations...

(3).Advertisement: display platforms, signboards, fascia, shop fronts...

4. Feature of CC Aluminium Sheet As Per ASTM B 209M - 06

Surfact Quality :

Be free from Oil Stain, Dent, Inclusion, Scratches, Stain, Oxide Dicoloration, Breaks, Corrosion, Roll Marks, Dirt Streaks and other defect which will interfere with use,

Mechenical Property:

Chemical Composite and Mechanical Property

5. Certificate of CC Aluminium Sheet As Per ASTM B 209M - 06

SGS and ROHS(if client request, paid by client), MTC(plant provided), Certificate of Origin(FORM A, FORM E, CO), Bureau Veritas and SGS (if client request, paid by client), CIQS certificate

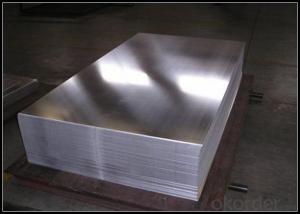

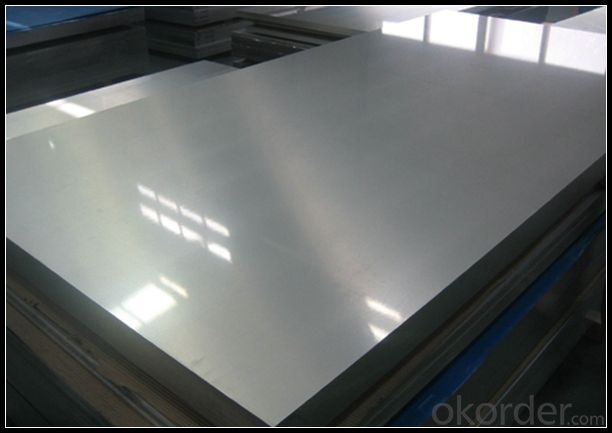

6. Image of CC Aluminium Sheet As Per ASTM B 209M - 06

7. Package and shipping of CC Aluminium Sheet As Per ASTM B 209M - 06

First, plastic cloth with drying agent inside; Second, Pearl Wool ; Third, wooden cases with dry agent , fumigation wooden pallets, aluminum surface could cover blue PVC film

8. FAQ

1) What is the delivery time?

Depends on actual order, around 20 to 35 days

2) What is the QC system:

We have QC staff of 20 persons and advanced equipment, each production is with MTC traced from Aluminum ingot lot.

3) What market do you mainly sell to?

Australia, America, Asia, Middle East, Western Europe, Africa etc

- Q:What are the weight-saving benefits of using aluminum sheets in different applications?

- Using aluminum sheets in various applications offers several benefits for weight-saving. Firstly, aluminum is a lightweight metal with a density much lower than commonly used materials like steel. This means that by replacing steel sheets with aluminum sheets, significant weight reduction can be achieved in different applications. The reduced weight of aluminum sheets is especially advantageous in transportation industries. For instance, in the automotive sector, using aluminum sheets for body panels, chassis components, and other structural parts can significantly lighten the overall weight of vehicles. This weight reduction leads to improved fuel efficiency as it requires less energy to move the lighter vehicle. Additionally, lighter vehicles generally exhibit better acceleration, handling, and braking performance. In the aerospace industry, the weight-saving benefits of aluminum sheets are even more crucial. Every additional kilogram of weight on an aircraft can increase fuel consumption and operating costs. By utilizing lightweight aluminum sheets in the construction of aircraft structures such as wings, fuselages, and engine components, the overall weight of the aircraft can be reduced, resulting in improved fuel efficiency and extended flight range. The construction sector also highly values the weight-saving benefits of aluminum sheets. Due to their lightweight nature, aluminum sheets are often used in building and infrastructure construction. This characteristic not only makes installation easier but also reduces the load on the building's foundation. Moreover, using aluminum sheets in construction can lead to cost savings as lighter materials require less support structure and can be transported more efficiently. Furthermore, the weight-saving benefits of aluminum sheets extend to various other applications such as packaging, electronics, and consumer goods. In packaging, aluminum sheets are commonly used for lightweight and flexible packaging materials, reducing shipping costs and environmental impact. In electronics, aluminum sheets are used in devices like laptops and smartphones, where weight reduction is desirable for portability. Lastly, in consumer goods, aluminum sheets are utilized for producing lightweight and durable products such as furniture, cookware, and sports equipment. In conclusion, the weight-saving benefits of using aluminum sheets in different applications are significant. Aluminum's lightweight nature allows for weight reduction in transportation industries, improved fuel efficiency, better performance, and extended flight range in aerospace applications, cost savings, and easier installation in construction, as well as various advantages in packaging, electronics, and consumer goods. Overall, aluminum sheets provide a versatile and efficient solution for achieving weight reduction and enhancing performance in diverse industries.

- Q:what family does aluminum belong to?its NOT the boron or aluminum family.i know its group 13. i need the family name.please help

- Aluminum is an orphan metal- (orphans appear in groups 3, 4, and 5 of the periodic table). They are called orphans simply because none belongs to a clearly defined family (like alkaline earth, transition metals, halogens, etc). Sometimes aluminum and the three elements below it in Group 3—gallium, indium, and thallium—are lumped together as the aluminum family, but that's not a clearly recognized family.

- Q:Are aluminum sheets suitable for chemical filtration applications?

- Aluminum sheets prove to be a fitting option for chemical filtration applications. Renowned for its outstanding corrosion resistance and durability, aluminum emerges as a trustworthy selection for chemical filtration systems. It diligently sieves out impurities and contaminants across diverse chemical procedures, encompassing the separation of solids from liquids and the elimination of hazardous substances. Furthermore, aluminum sheets boast resilience against elevated temperatures and pressures, rendering them well-suited for an extensive array of chemical filtration applications.

- Q:i have a aluminum bicycle the first time i painted it i painted over the original paint(didnt know any better). The second time i sanded it down with some paint left on it. Now this time im sanding it but im using 60grit it looks good to me is 60 grit to much.

- You screwed up. 60 grit should NEVER come in contact with aluminum... those scratches will never come out. NEVER have an aluminum frame sandblasted. You'll need to have it soda blasted or walnut shell blasted. You should be using 220 grit ALUMINUM OXIDE paper- it is white in color. My bet is that you are using garnet- the brown stuff, or maybe coated paper. You MUST use aluminum oxide. I have answered the question to paint a bike a hundred times. Just click on Discover and type in the words paint a bike without quotes. Theres your answer.

- Q:How are aluminum sheets different from aluminum plates?

- Aluminum sheets and aluminum plates differ primarily in terms of thickness and applications. Aluminum sheets are typically thinner, ranging from 0.2mm to 6mm in thickness, whereas aluminum plates are thicker, usually starting from 6mm and going up to several inches thick. Aluminum sheets are commonly used for general purposes such as packaging, signage, and roofing due to their lightweight nature and flexibility. They are often bent, formed, and cut into various shapes and sizes to fulfill specific requirements. On the other hand, aluminum plates are typically used in applications that require higher strength and durability. With their greater thickness, they provide enhanced structural integrity and are commonly utilized in industries such as aerospace, automotive, and construction. Aluminum plates can withstand heavy loads and are often used as structural components in buildings, aircraft, and machinery. In summary, the main differences between aluminum sheets and aluminum plates lie in their thickness and the specific applications they are suited for. Sheets are thinner and more flexible, suitable for general purposes, while plates are thicker and stronger, ideal for heavy-duty applications that require structural integrity.

- Q:What are the different types of finishes used for decorative aluminum sheet?

- The different types of finishes used for decorative aluminum sheet include brushed, polished, anodized, embossed, and powder coated finishes.

- Q:How does the surface treatment of aluminum sheet affect its appearance?

- The appearance of aluminum sheet is greatly influenced by its surface treatment. Natural aluminum has a shiny and reflective surface, which can be improved or modified through different surface treatments. One popular surface treatment for aluminum sheet is anodizing, which involves the creation of a protective oxide layer on the surface through an electrochemical process. This treatment offers a wide range of colors and finishes, ranging from vibrant and opaque to translucent and metallic. Anodized aluminum sheets have a sleek and modern look, making them commonly used in architectural and decorative applications. Another option for surface treatment is painting or powder coating. These processes involve applying a layer of paint or powder onto the surface of the aluminum sheet. This treatment allows for customization in terms of color, texture, and finish. Painted or powder-coated aluminum sheets can have a smooth and glossy appearance or a textured and matte finish, depending on the desired outcome. This treatment is frequently utilized in industries like automotive, aerospace, and construction, where aesthetics and durability are important. Additionally, aluminum sheets can undergo mechanical surface treatments like brushing or polishing. Brushing involves creating parallel lines on the sheet's surface using abrasive pads, resulting in a brushed or satin finish. This treatment gives aluminum sheets a contemporary and industrial look. On the other hand, polishing involves buffing the surface to a high gloss and mirror-like finish. This treatment is often used for decorative purposes, such as in the production of jewelry or household items. In conclusion, the surface treatment of aluminum sheet plays a crucial role in determining its appearance. Whether it is anodizing, painting, powder coating, brushing, or polishing, each treatment offers a distinct visual effect that can enhance the aesthetic appeal of the aluminum sheet for specific applications and industries.

- Q:If something is wrong, what kind of glue can be used for bonding the stainless steel sheet and aluminum sheet? The area may be very big. What are some common or good glue to buy?

- There are two methods: 1 AB glue or epoxy resin adhesive. 2. If the thickness of the two plate is greater than 8MM, it can be fixed by flat screw. Hope to be available.

- Q:Can 101 aluminum sheets be used in the production of decorative panels?

- Indeed, decorative panels can be produced with the use of 101 aluminum sheets. Recognized for its exceptional formability and resistance to corrosion, 101 aluminum stands out as a commercially pure alloy. This alloy's remarkable attributes render it appropriate for diverse applications, decorative panels being one of them. The aluminum sheets have the capacity to be effortlessly molded, trimmed, and crafted, enabling the formation of intricate designs and patterns for ornamental intentions. Furthermore, the corrosion resistance of 101 aluminum guarantees that the panels will retain their visual appeal throughout time, even when exposed to outdoor conditions or environments with high moisture levels.

- Q:Can I bake falafel patties in the oven using an aluminum foil on top of the pan I am using to put in the oven? Will the aluminum foil catch fire in the oven? Also, if I put the aluminum foil I wouldn't have to grease up the foil with oil...the patties just wont stick to aluminum foil right?

- The foil will not burn in a normal oven, it is best to oil it lightly as it can stick.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

CC Aluminium Sheet As Per ASTM B 209M - 06

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords