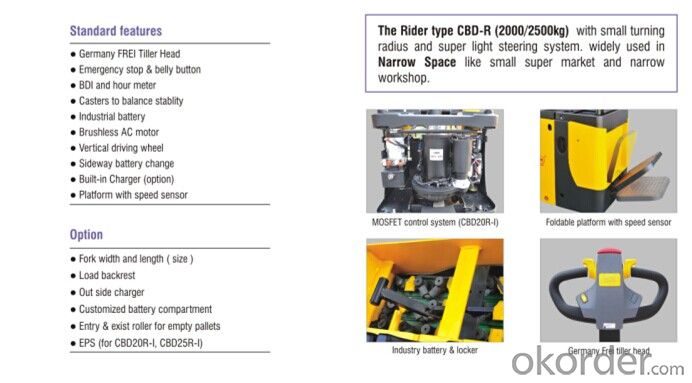

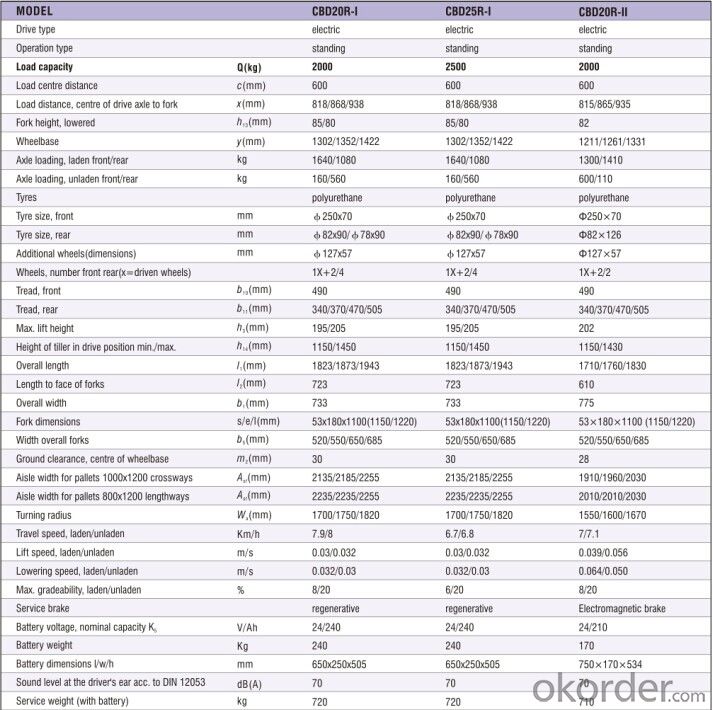

CBD 20R-I ELECTRIC PALLET TRUCK

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

- Q:Urgent, please go to logistics expert, the question about the warehouse

- With the deepening of the reform and opening up, China's pharmaceutical industry also fast lane of development, the entire pharmaceutical industry production grew by an average of 17.7% a year, compared with the national industrial average annual growth rate of 4.4%, but also higher than in the developed countries in the world major drug. Over the past 30 years, the average growth rate has grown by 13.8 percent, making it one of the fastest growing medical markets in the world. According to the state economic and trade commission statistics, the pharmaceutical industry production, sales growth in 2002, gross industrial output value (constant) 21.95 billion yuan, an increase of 20.1%, down 0.9% growth than 1-2 month. The main business revenue was 196.100 million yuan, an increase of 12.8%, an increase of 2 percentage points from January to February. Ratios of 94.4%, year-on-year, and 1-2 month dropped 2.5 and 0.7% respectively, profit growth, the total profit of 990 million yuan, an increase of 12.8%, slower than 1-2 month fell 1%. According to the above data, the scale benefit of the pharmaceutical industry in China is emerging, the potential is big, the growth is good, the stable, healthy, rapid development stage. The graduation internship I came to yunnan double crane pharmaceutical company, personally experienced enterprise facing the opportunity and pressure, at the same time to realize enterprise logistics rationalization in the enterprise of great significance.

- Q:What is the relevant content of the flow of materials, storage and usage

- The transport system, the choice of carrying technology and equipment. To some extent determine the distribution and operation of the production logistics system. And the efficiency, complexity, size and economic effect of the production system are very strong. The important problem in production logistics is choosing the right transport equipment. These devices should be able to adapt to the nature, weight, shape, size and material flow of the moving material. We need to keep the fixed investment of the equipment low, and we need to meet the demand for moving. There are several kinds of moving, intermittent, and round-trip, which are divided into horizontal, oblique, vertical or two-dimensional direction. Other transport requirements include: channel flow shunt, location stop, high-speed moving, product placement, etc. Also consider moving objects and environments such as forming, powder, drying environment and cleaning environment. Finally, the mode of carrying, the combination of the equipment and the quantity of the specification are determined. The speed requirements of the transport are based on the production beat.

- Q:The development of material handling

- Due to the improvement of industrial production automation degree and the expansion of production scale, in the process of the production and material handling cost has had a huge impact on the profit, to promote more and more used in the production of large enterprises, efficient, automated material handling machinery. Along with the material handling equipment manufacturing enterprises in the international market competition ability, and stable and continuous development of economic construction in developing countries the market need, the world market for material handling machinery in our country's overall demand will continue to increase.

- Q:What are the potential defects of the automated material handling system?

- The automatic stacker is a stack of finished goods that will be wrapped in a sealing machine, and the finished product will be finished by the machine hand. Demolition yards of technical difficulty than pallet, the main reason is that the original pallet good tray due to finished product deformation and vibration in the transport process, make product tray deformation, cause every demolition yards of finished tray deviating from the ideal position. In addition, due to the demolition yards tray is finished box close to finished product box, general instrument cannot be inserted between the two cases, make clamping product box, the solution is to use a vacuum sucker is finished. The mechanical manual stacker has the following advantages compared with the traditional high stacker machine. Secondly, the failure rate is low; Third, the area is small. Fourth, the cost of human resources is low.

- Q:The function of material handling

- Material handling USES all kinds of power and transport machinery to keep the material, such as count, punctually, safely, economically, and to the designated place. It is closely related to the choice of site selection and professional cooperation in the outside material handling machinery factory.

- Q:Why should we emphasize unitization and standardization in material handling

- Reducing the degree of climate impact, ensuring normal work, accelerating the flow of goods and improving efficiency. 1) logistics base module The logistics base modulus is the minimum size of the standard size of the logistics system. In basic module size was determined, the size of the various specific standards, should be based on basic module size, select the integer times to the prescribed standards for size, foundation modulus size is determined, just a standard size in multiple choice, it can be used as a standard of other size.

- Q:There are three things to do when the material is stacked up and down

- Fire prevention, waterproof, and do not exceed the limit.I hope my answer will help you.

- Q:The principle of material handling

- Planning principles: plan all material handling and storage activities to achieve maximum overall operational efficiency. 2, the principle of system, to integrate various handling activities and suppliers, purchase, storage, production, testing, packaging, storage management, shipping, transportation, and the customer's operating system as a whole.

- Q:The beneficial effect of material handling machinery

- Material handling machinery is serving the production, its design and type selection should be subject to the needs of the production process, new material handling machinery but also often leads to the change and improvement of the manufacturing process. For example, the emergence of bucket wheel stacker reclaimer, formed the bucket wheel stacker reclaimer for heart, belt conveyor for blood vessels, the electronic computer is the nerve center of automation of large bulk material handling system, which changes the ports, mines and the layout of the power plant and so on of the bulk yard; It can simplify the structure of the factory and reduce the cost of construction.

- Q:Material handling system in the factory

- Improve logistics quality (material loss, high transport efficiency, safety operation), lower logistics cost (including handling, storage etc.).

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

CBD 20R-I ELECTRIC PALLET TRUCK

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

New products

Hot products