Catwalk for Ringlock System Metal Planks with Hook 500*50*1.8*900-3000mm CNBM

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

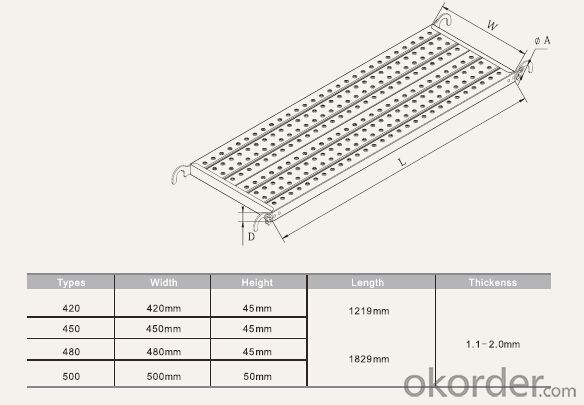

Quick Details of Catwalk for Ringlock System Metal Planks with Hook 500*50*1.8*900-3000mm

Material :Q235/Q345 carbon steel

Surface treatment :Hot dip galvanized, pre-galvanized

Thickness :1.0mm,1.1mm,1.2mm,1.5mm,1.8mm

Length :900MM/1200MM/1500MM/2000MM/2500MM/3000MM

Descriptions of Catwalk for Ringlock System Metal Planks with Hook 500*50*1.8*900-3000mm

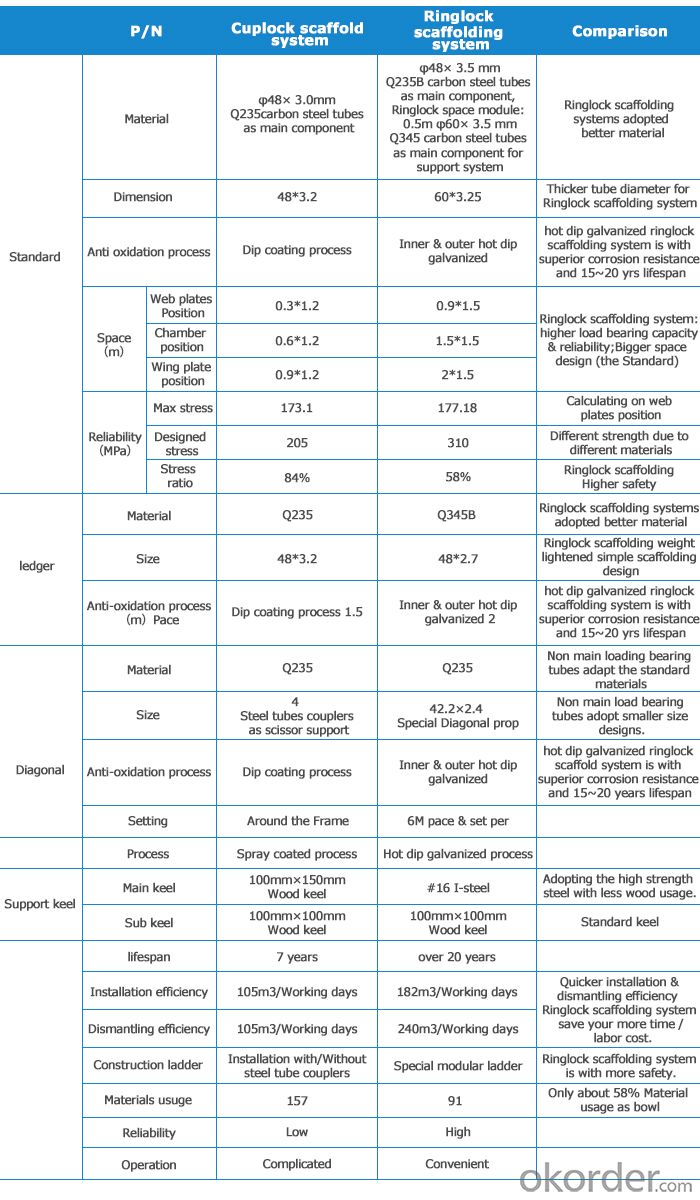

Ringlock scaffolding and ringlock support system are popularly used in building construction, external scaffolding, cast-in-situ beam, formworks support, canopy frame, bridge & tunnel, stage construction applications and welcomed by building construction companies, construction & decoration companies, leasing companies, media & advertising companies and other users。

Our patented Ringlock scaffolding and Ringlock support system with surface galvanizing process provided the buyers with higher safety & benefits. 7000 tons annual output.

The strong ringlock scaffold system is with 2~3 times installation & dismantling efficiency higher than the cuplock scaffolding system, but only with half steel usage and 75% investment cost.

Our low cost & high benefits Ringlock scaffolding system with hot dip galvanized surface treatment are easy to installation & disassembly.

Our Ringlock Scaffolding and Ringlock support system with 200 KN high loading bearing capacity are buyers’ safe & professional choice.

Patented R&D and production; Single personal installation with a hammer only. Greatly saved the steel usages compared to steel tube with couplers.

Catwalk Details:

FAQ

1. What is considerations of Scaffolding installation?

There must be a fire protection measures and specialist care, safety personnel patrol inspection when electricity, gas welding work on the scaffold,

(1) scaffold frontage hurtful to prevent falling objects protection is required.

(2) During take down the scaffolding, fencing and warning signs should be set up on the ground, prohibit others person besides the operator

2.What are the certifications of your products?

Certified by SGS, BS1139, EN74, Local Test Report.

3. How long is the warranty period for your product?

Our products warranty is 2 years.

- Q:I would like to ask how much scaffolding steel prices, scaffolding steel pipe use what are the requirements?

- The general price of 3800-4200 yuan per ton, you need to see the material and specifications.1 scaffolding steel pipe material Q195, Q215 or Q235, 2 scaffolding steel pipe specifications of phi, phi, phi, phi, phi, phi, 3.25, phi, phi, phi, 2.752, 5, 3 scaffolding steel pipe length of 1-6 meters, half a meter specifications; according to customer requirements specifications4 scaffolding steel pipe standard SY/T5768-

- Q:Scaffolding installation and precautions?

- Began to set up the column, should be set up every 6 span of a throw support, even after the installation of the wall is stable, can be removed according to the circumstances.

- Q:there is also shrubs and trees planted on the base of the wall and 14 feet from it

- A little late to be asking that question if you already have the contract, isn't it?

- Q:Im a wimp for pain and im looking to get my scaffolding done. i want to know how painful it isI already have both lobs pierced and stretched to an 8mm, will the pain be similar to that?

- You sound like you have a low tolerance for pain if you say you're a wimp haha, which means yeah it'll probably hurt you. It'll hurt more than the lobes because it's cartilage, and for the same reason you'll hear a popping noise as the hole is made. You won't be taken over by deathly pain or anything like that, it'll probably be sensitive for a few days after too so careful not to knock it against anyone/ anything. But if you want it bad enough, the pain will be bearable.

- Q:Scaffolding Vertical Standard, Length: 3000mm, Part Number AS1001

- Please okorder Type ‘Aluminum Scaffolding+supplier+your location’ into its ‘Search’ panel, and click on ‘Enter’. Several pages of site listings giving details and links of suppliers who offer Aluminum Scaffoldings in, or near, your locality will be presented to you. Contact them, one by one, and then choose the supplier who suits your specific needs best. Happy hunting !

- Q:Okay so I got a scaffold piercing about 5 days ago now. I've been cleaning it with Claire's piercing stuff. What I do is I pour it onto a little bit of loo roll and squeeze it all out on where the holes are. I have not been twisting it at all, but my friend told me that I should soak it in warm salty water and twist it twice a day. I have no idea what to do now as I have researched it and some people say that I shouldn't twist it because it will drag more bacteria into it and could get it infected. Also I have massive scabs around both ends of the bar, I've tried to pick them off as they are pretty uncomfortable, but it didn't work as they are rock solid, so how do I get these off? I have no idea what to do, my piercer didn't say anything about twisting it just cleaning it twice a day. Oh and if it helps I'm 13:) Thanks. X

- Why are you using Claire's crap? You need to be doing sea salt soaks twice a day for 5-10 minutes each soak with 1/4th of a teaspoon of non-iodized sea salt to 8oz of hot water. Don't twist them as that drags in crust and bacteria and tears up the inside of the piercing. Stop trying to pick stuff off from your ear and go have a reputable piercer check out the scabbing, it could be crust it could be something wrong. If your piercer didn't tell you to do sea salt soaks to keep it clean go to a better piercer.

- Q:What does scaffold one's days mean? kill time?

- In 60 years of using English in Britain I have not come across that expression, so it is probably rare. Scaffolding is put up to help build or repair tall buildings, so possibly that expression means 'to do something useful with one's time.' But a scaffold is also, historically, a place of execution (legal killing of prisoner), so the expression could mean indeed 'wasting time'. I have a faint feeling that 'scaffold one's days' was written by a non-native speaker of British English. It may be more common in the USA.

- Q:along with this question, -what does she think about during this time period?-how does she apprear on the scaffold? -who does she see and how does she feel?THANKS!!=]

- Here is a good analysis and summary from Shmoop.

- Q:Salt doesn't really make any different when cleaning infact I think it makes more dried skin to get stick on the bar. My side piercing is fine but the one closest to my eye is painful when pushed or touched I think this is because I accidentally sleep on it without realising. It's red but it has no lump around the piercing is it infected or is it just trying to heal?

- problematic problem. browse at search engines like google. this could help!

- Q:Bracket cast-in-place beam bracket must use bowl buckle scaffold, can not use fastener type scaffolding, there is no mandatory requirements, or specification file requirements!

- 5.2.5, the calculation of the column, a clear calculation of the type of stud.6.2.4, clear the structure of fastener type column.Local documents, it is not possible to regulate, do not allow the use of fastener type scaffolding. But the top of the column, to use the provisions of backwater, specification.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Catwalk for Ringlock System Metal Planks with Hook 500*50*1.8*900-3000mm CNBM

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords