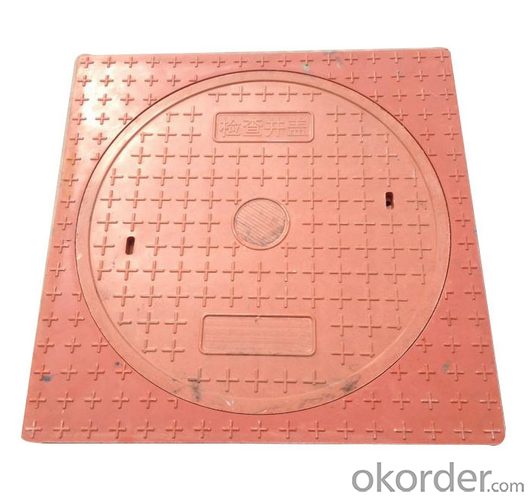

Cast OEM ductile iron manhole cover with superior quality for mining

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 set

- Supply Capability:

- 4166 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description

1) production standard: EN124 standard

2) Material: grey iron, ductile iron

3) Type:round type and Square type,triangle

4) Sand casting

5) Color:Red,black,grey,green

6)ISO9001:2008

Specification

| Item No. | Class | Clear Opening(mm) | Frame Size(mm) |

| TD1221 | D400 | 1220*675 | 1378*831 |

| TD1222 | D400 | 1220*675 | 1370*830 |

Advantages

Good compressive, bending and impact strength, anti-rust, waterproof, serviceable life (at least 30 years).

The quality meets the same kinds cast ion manhole covers but the cost is 30% lower than other companies.

Packaging & Shipping

Packaging: Details Pallet with bubble film, Carton or with pallet,

Delivery Detail: 8 days if your order is 20"container

FAQ

1.Can I get free samples?

A: Yes, we can provide you the free sample, but you need to bear their own delivery costs.

2.Can I request to change the form of packaging and transportation?

A:Yes,We can change the form of the packaging and transportation according to your request, but you have to bear their own costs incurred during this period and the spreads.

3.Can I request to advance the shipment?

A: It should be depends on whether there is sufficient inventory in our warehouse,

4. Can you provide a discount for your goods?

A: Yes,we can offer you a 10% discount if you place an drder of 300 sets one time...

- Q:How to solve casting defect casting?

- Different defects, different solutions, some shortcomings, the current domestic level can not be resolved

- Q:For example, casting parts contain many holes, inclusions and other defects, the size and the number of holes exceed which limit is not qualified

- According to the grade of the parts, according to the relevant standards, the regular drawings will be noted in the technical requirements of the parts.

- Q:Which surface is coarser for cast iron or cast steel castings? Why?

- The surface of the steel is more rough, because the coating sand cast steel cast iron particles compared with graphite coating degree, the other one is to get a better air permeability and collapsibility of sand, the compaction degree is smaller than iron. Roughness mainly depends on the surface roughness on the surface of the sand.

- Q:What are the casting parts processing engineering?

- According to the classification of process methods, sand casting and special casting.

- Q:Casting parts need to be subjected to the kind of heat treatment after the weldment is finished

- Annealing is needed to eliminate stress and refine grain

- Q:In theory, which is more expensive, forging parts or casting parts?

- Compared with the price, the product with the same simple structure eliminates the material factorsThe forgings must be more expensive

- Q:Casting parts by shot blasting, spray painting, baking after the formation of very small rust spots, how to solve ah?

- The first process is very important. Shot blasting must be thorough. The solution is to wipe the surface of the paint with a release. Re shot

- Q:Heat treatment process and purpose of casting parts

- Objective: to stabilize tissues, eliminate or substantially reduce internal stress.

- Q:The cause of fracture and why there is no toughness

- This question is too broad, see what the casting casting Oh in order to reduce the wayward cast steel, ductile iron, gray iron and white iron, you can choose the material according to their own requirements.

- Q:the parts of the threaded hole is casting, casting the hole directly, and then tapping or casting, and then punch 10When the casting is ready, punch it again before tapping it Is the hole casting good or is it punched and tapped on the drilling machine after casting?

- Single for this problem, the direct casting out of course good. But many times because of the limitations of the process, so we choose the post-processing hole

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Cast OEM ductile iron manhole cover with superior quality for mining

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 set

- Supply Capability:

- 4166 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products