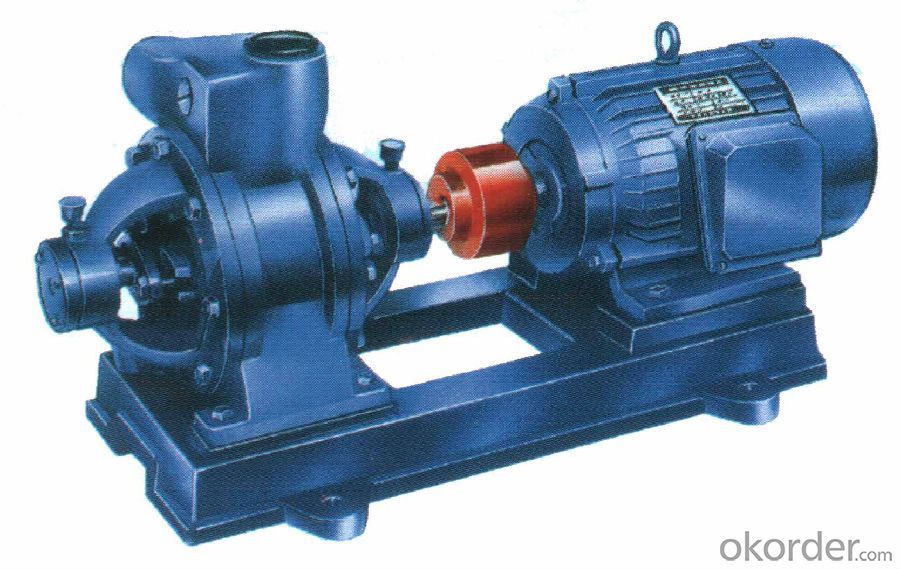

Cast Iron Diesel Fire Fighting Pump High Quality

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 1000 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

Cast Iron Diesel Fire Fighting Pump High Quality

Company Introduce

My company has more than 40 years history, is the China general machinery pump industry association member units.

The company has organized product research and development team, experienced high, intermediate technical staff.Complete production and processing, inspection, testing (pump performance test platform), and other equipment, to ensure that product quality is stable and reliable.Over the department, provincial, municipal and industry product quality supervision and inspection (smoke), only one is qualified to go through.Timely quality perfect after-sales service in place, favored by the majority of new and old customers rely on and praise.

The company has successfully passed the national industrial products production license, ISO9001 quality system review replacement work.Relevant product standards (enterprise), metrology, standardization management system, etc., have been acceptance by the superior department in charge of the inspection.Related to product development, production management, sales and after-sales service, are performed according to the system management standard.

Product Parameters of Cast Iron Diesel Fire Fighting Pump High Quality

| Capacity: | 20-200L/s |

| Head: | 0.3-1.28MPa |

| Speed: | 2900r/min、1450r/min |

| Power of fitted motor: | 0.75-250kW |

| Inler diameter: | 25-300mm(1"-12") |

Application Range of Cast Iron Diesel Fire Fighting Pump High Quality

It is mainly used for the water supply for the fixed firefighting system of both industrial and civil building

fire hydrant fire-extinguishing system,

automatic spraying,

fire-extinguishing system.

Cast Iron Diesel Fire Fighting Pump High Quality Superiority

High efficiency

Reasonable design

Reliable operation

Long in service time

Easy maintenance

Low running cost

Picture Show

Why choose us

1.Exported to 58 Countries

2. More than 90% customers make payment before meeting us!

3. Reorder rate up to 80%

4. Never sell any renewed pumps

5. Focus on middle and high-end market,we never seize market by using inferior material

FAQ

1. How to get our quotation in time, pls answer following questions:

1)What liquid do you transfer?oil ,food or corrosive chemical liquid,with solid particle or not and so on

2) What's the flow or capcity (m3/h, L/m)?

3) What's the discharge head (m, feet, Mpa, bar )

If you do not have any request, we will do as our normal standard.

4) Contact us by under business card information

2.OEM: Ok

3. MOQ: 1set

4. Package: Standard export wooden case(also according to your requirements)

5. Shipping ways: By sea, By air, By express

6. Lead time: 3-15days

7. Warranty Period: One year, except spare parts

Trading market

After-sales service

Transportation

Related products

|

|

Fire Pump Cast Steel High Speed China Made | Cast Steel Centrifugal Pump High Pressure |

| http://www.okorder.com/p/fire-pump-cast-steel-high-speed-china-made_976663.html | http://www.okorder.com/p/cast-steel-centrifugal-pump-high-pressure_975173.html |

- Q:I moved into a house on a rural property in January, and we live off tank water and have a Grunfos PT18 pumping all our water into the house.The problem is, not all the time, but alot of the time my pump stays on after having a shower, the motor keeps running and restarting continuously as if it is desperately trying to pump more water through, until I go underneath my house and literally turn it off at the powerpoint, wait for a bit then turn it back on. I am scared if I leave the motor keep going like that it will burn my pump out. Does anyone have any suggestions on how I can fix this problem, or why it may be doing this, or is something causing it?Thankyou in advance, from someone who has next to no knowledge about pumps!!

- Sounds like it's waterlogged. That's what it's called when the water and the air in the resevoir tank mix, and the volume of air gets so small as to not be able to provide any decent compression with which to push water through the system. At that point, any time you open a fixture, the pressure drops enough to turn on the pump, and when you turn off the pump, if it's just right, it will turn off and then back on, then off, then on, back and forth till you shut it off and it can set and stabilize, till you need water again. The solution is to reintroduce a sizeable amount of air back into the top of the tank. If it's an older tank, without a bladder, (identified by the small bulge around the center of the tank and either a blue or rust color), then the best way is to simply drain the tank and restart the system. That way it will trap all the air in the top of the tank and you'll have enough pressurized air to push a gallon or two of water out, before the pump needs to kick on again. If it's the bladder type, with the bulge, then the bladder has blown and you're, in effect, working with a standard resevoir tank now, except that it will have an air valve in the top like a bicycle tire, so you can pressurize it with an air tank. If so, open some fixtures, start pressurizing the top of the tank and blow all the water out of the system. Once it's dry, put about 20 lbs. of pressure in the tank and start up the pump. You should be good to go.

- Q:Is it ok to drive a car with a bad water pump?

- Depends on how bad it is. I had a leaking one for about a month before I took it in. I just kept adding water. So it realy depends on what is bad, the bearings, or the impeller. If it overheats, thats a problem and will blow your engine.

- Q:We are leasing land from a friend to put horses on. We're in the process of building a barn. We don't want to run water out there because its too much trouble for the meter and everything, but someone said to get a water pump and pump the water from the pond and filter it and use it. I have no idea what all we need or what kind of pump to get. Helpp!

- flow to sears and get a shallow nicely pump that has a foot valve and runs on 115vac consistent with probability a a million.5 hp ..if the top(the uphill area plus the pipe loss ) gets to sizeable you're able to desire a lager hp yet a a million.5 with a 25 ft of head could supply 9gpm at 40 psi . Oh confident is that's a closed gadget be certain an get a intense stress shrink off change..they're real decrease priced... from the E..

- Q:Does the pump accessories have a shelf life?

- Yes, 3-6 months for wearing parts, 12 months for general accessories, 10 years for shell type. Specific depends on whether the materials and user use conditions are bad to decide.

- Q:The pump assembly and the pump are not a thing

- Yes, all the auto parts are called assembly, and the pump is the same. It's called water pump assembly. Also, the pump half assembly is the water pump head.

- Q:i learned from wikipedia that the water pumps back to reactor where it is heated again and the cycle begins again. but then i saw this diagram

- As you factor out it was once the double-punch of the earthquake and tsunami that caused the problems at Fukushima. The diesel mills have been enough to control the pumps to cool the reactor but then the tsunami got here and swamped them. Shutting down the reactor after an earthquake is typical defense system. The diesel turbines had been designed to be a backup in the occasion of an earthquake. They functioned quality even after the large quake. If the quake didn't occur, but instead the planet was once just hit with the aid of the tsunami, the other planets in unaffected areas of Japan would still be operating so this implies the engineers onsite might have jerryrigged anything in order that the pumps would be powered through the country wide vigor grid even though the diesel pumps were knocked out. No longer shutting the reactors down would have resulted in much more radiation being launched as a result of the damaged structures and containment units.

- Q:I have a leak coming from the water pump that flows down on the side of the AC compressor before landing on the ground. I cannot verify exactly where the leak is coming from on the pump, but I am sure it is the pump leaking because it also sounds bad like rattling. My question is do I have to remove any other components, such as the AC compressor to be able to remove the water pump. I would be great full for any suggestions.Regards,Steph

- First you have to mention which E320 you have. It could be either a gasoline or diesel model and the E320 model designation has had the M104 I6, M112 V6, M613 I6 diesel, and M642 V6 diesel under the hood. The water pump is not located in the same place on all engines.

- Q:I recently got the water pump replaced on a 99 Oldsmobile Intrigue GL (3.5L V6), and ever since the temperature gage seems to be running higher...between half way and the 3rd line, where before it was replaced it never got above the second line. It is doing this when I slow down and stop at lights. Once I get going the temperature does drop. Is this normal, or did they do something wrong?

- There's a few different things that could be causing your problem. 1: Did they change the thermostat? If so, they may have replaced it with a defective one. If not, then it may need to be replaced. 2: What was the reason the water pump was replaced in the first place? if it was for any other reason than leaking then this could be causing your problem. 3: They might not have gotten all the air out of the system. when you drain all the water and then fill system back up, there are large air pockets in engine that must be bleed out. If not, these air pockets will get trapped behind the thermostat and cause the thermostat not to open when it's suppose to! 4: Are your cooling fans coming on? If not, you may have a bad temp sensor, causing your fans not to come on while you are stopped. This type of problem is hard to narrow with out seeing it in person. I would take it back to the place that replace your water pump and see if they can figure it out.

- Q:What's a small soft pipe for a submersible pump in a fish bowl? How do you use it?

- Filter pump for oxygen spray. If the filter pump water flow, you can throw oxygen flowers, you can not use. With that pipe, it's loud and kind of

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Cast Iron Diesel Fire Fighting Pump High Quality

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 1000 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords