Case Packer Machine for Packaging Industry

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 unit

- Supply Capability:

- 50 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Case Packer Machine for Packaging Industry

1. Product Description:

Automatic machine for packing product into cartons with a gravity system with moving supports fitted on the in feeding lines.The vertical up-down movement of the cartons which takes place on the loading conveyor is synchronized with the introduction of the bottles and powered by belts. It is a special ideal for plastic products.

2. Product Features:

Faster return on investment.

High-quality and advanced device configuration, use the international generic accessories.

Reliable main drive gear and synchronous bottle blocking, bottle grabbing and bottle guiding system.

Reliable bottle input, bottle counseling, synchronous bottle transporting, sub-bottle system.

Expand production, reduce material waste and improve yield.

Equipment with flexible application and easy to operate.

3. Product Parameters:

Model | ZX15 |

Capacity(CPM ) | 15 CPM |

Application | water, milk, seasoning etc. |

Bottle material | PET, metal |

Bottle shape | around, square, oval |

Bottle size(mm) | Ø50~85mm |

Equipment dimension | 1400×860×1870 (L x W x H, mm) |

Power consumption | 0.75Kw |

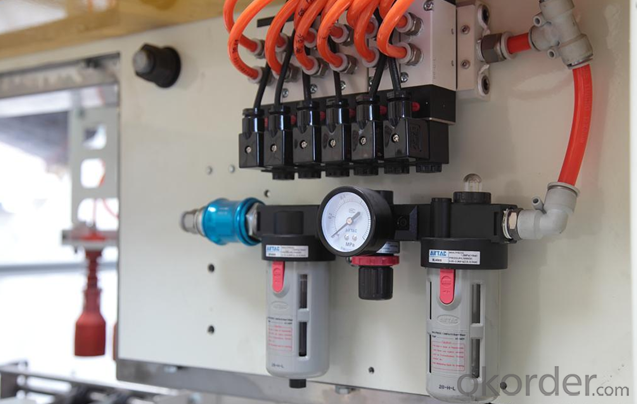

compressed air | (a)pressure: 0.6MPa |

Main Power supply | 3P AC380V 50/60Hz |

Auxiliary power supply | AC220V; DC24V |

Equipment weight | 0.5T |

Equipment noise level | ≤85 dB(A) |

4. FAQ:

Q1: What is your delivery time?

A: Generally, the delivery time is 45-60 days after receive the deposit, big production line may take more time.

Q2: What is the payment term?

A: We accept both T/T and L/C. Most customers pay by T/T.

Q3: What kind of after-sevices do you provide?

A: If it is not big problem, we can solve it by emails, phone etc. If it can’t work, our engineers can go to overseas to install and adjust the machine and solve the problems.

5. Product Pictures:

- Q:What are the components of mechanical equipment (automatic equipment), steel or iron or anything else?

- I have been away from this industry for a long time, and I can't give you any specific suggestions. But I think you should be more specific in the process of machining. It is estimated that it is a precision machine component, and the material requirements are relatively high. But I think in principle, we should look for local steel mills with special steel production capacity, and the other one depends on the local technical strength, such as northeast China and Shandong, where the strengths are in large equipment. Jiangsu Shanghai side of the precision mechanical technology strength in the country should be relatively strong.

- Q:What are the main parts of small vacuum machines?

- The composition of the vacuum pump: vacuum pump, motor, vacuum chamber, sealing strip, plexiglass plate, upper cover, air bag, solenoid valve, etc..1, the upper and lower vacuum chamber and the sealing ringAt present, usually called vacuum machines are cavity structure, from the upper vacuum chamber, the lower vacuum chamber and placed in the upper and lower vacuum chamber between the sealing ring. The upper and lower vacuum chambers are generally made of aluminium alloy, which are machined by milling or stainless steel sheets, welded and machined by flanging or moulding. There are also two upper and lower vacuum chambers which are made of aluminum alloy and stainless steel

- Q:A workshop to machine parts, 5 boxed 80, according to this calculation, there are 340 parts, 20 boxes can be fully loaded?

- 5 boxed with 8020 boxes are 4 times as many as 5 boxesIn other words, the 4 5 boxes are 20 boxes80 x 4=320So I can't finish it

- Q:Do you have to mark the length of a part in mechanical drawing? I also can be the mechanical cartography, really did not listen to the teacher said to the chief, in the book have not seen this sentence. Just listen to the teacher said, in the assembly plan to mark the total length, height, width. That's for the convenience of packing boxes. For example, I do not want to guarantee a part of its length, but in the middle of each size, I marked the total length is not wrong, and closed ring can also be the length of the ah. Now I work units that must mark the total length, and they compete for profit. I also don't know the basic knowledge of mechanical drawing. I wonder if there is a requirement for this rule

- A total length of a certain truth, such as easy cutting, easy processing (such as the big machine, easy to heat treatment), ease of assembly, so that people see, you should take control of size is not important for the free length to form a closed size.Mechanical drawing dimensioning can improve product quality and improve production efficiency, which is not necessarily inconsistent with mechanical drawing standards, which has a lot to do with practical experience, especially the choice of benchmark.

- Q:What's the price difference between feed packer and organic fertilizer packing machine?

- Because organic fertilizer and other chemical packaging machine compared to animal feed, it has a strong corrosive

- Q:As a mechanical component inspector, how do you improve the quality of your product?

- As a mechanical inspector, your job is to inspect the parts. You can't directly improve the quality of the product. You can't process the partsYou can control the quality of indirect suppliers or processors of products, so as to enhance the quality of the products.So you have to adhere to the requirements of national standard drawings or to suppliers or processors, so that the parts can meet the requirements of the drawings,

- Q:Hardware, furniture accessories, packaging machines exported much?

- Not much, but not less, the general exports in several countries around China, Europe, the use of hardware, furniture fittings, packaging machines are not many

- Q:Air conditioning installed in the outer machine packaging, found a small part, please master to help see what is this?

- You're right. It's a balance plate for fan bladesWhen the fan leaves the factory, must make the balance verification, achieves the balance standard, can leave the factory

- Q:Can the nylon vacuum packing bag be high and low temperature with mechanical parts?

- The following are the details and features of nylon vacuum packaging bags:1 、 nylon vacuum packing bag, high barrier:The use of different plastic material barrier performance varies greatly, to achieve oxygen, water, carbon dioxide, odor and other high barrier effect.

- Q:How to package machined parts?

- If it's not rusted, clean it and wrap it in a bubble bag. Place it in a cardboard box or wooden case

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Case Packer Machine for Packaging Industry

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 unit

- Supply Capability:

- 50 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords