Carbon Welding Electrode /Titanium Welding

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 100 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Carbon Welding Electrode /Titanium Welding

Quick Information for Carbon Welding Electrode:

Class: ER1100

AWS: A5.10

Conforms to Certification: AWS A5.10 ASME SFA A5.10

Weld Process: Tig (GTAW)

Specifiaction of Carbon Welding Electrode:

AWS Chemical Composition Requirements | |

Cu = 0.05 – 0.20 | Al = 99.0 min |

Mn = 0.05 max | Si + Fe = 0.95 max |

Zn = 0.10 max | Be = 0.0003 max |

Other = 0.05 each – 0.15 total | |

Available Sizes:

Upon Request, call for more information

Characteristics of Carbon Welding Electrode:

Type ER1100 can be used to weld base materials types 1060, 1070, 1080, and 3003.

Welding Filler Wire

Heat Exchangers

Food Handling Equipment

Rivets

Main Features of Carbon Welding Eletrode:

The proper choice of aluminum filler metal mainly depends on the base metal properties to be achieved and welding technique. Post weld cracking, corrosion resistance and behavior under elevated temperature also need to be taken into consideration. Cracking usually can be minimized by choosing a filler metal alloy of higher alloy content then the base metal.

Deposited Chemical Composition % (Typical)

Deposited chemistry is influenced by many factors so no typical analysis can be reported.

Deposited All Weld Metal Properties %

As-Welded

Deposited all weld metal properties are influenced by many factors such as weld process used, so no typical weld metal properties can be reported.

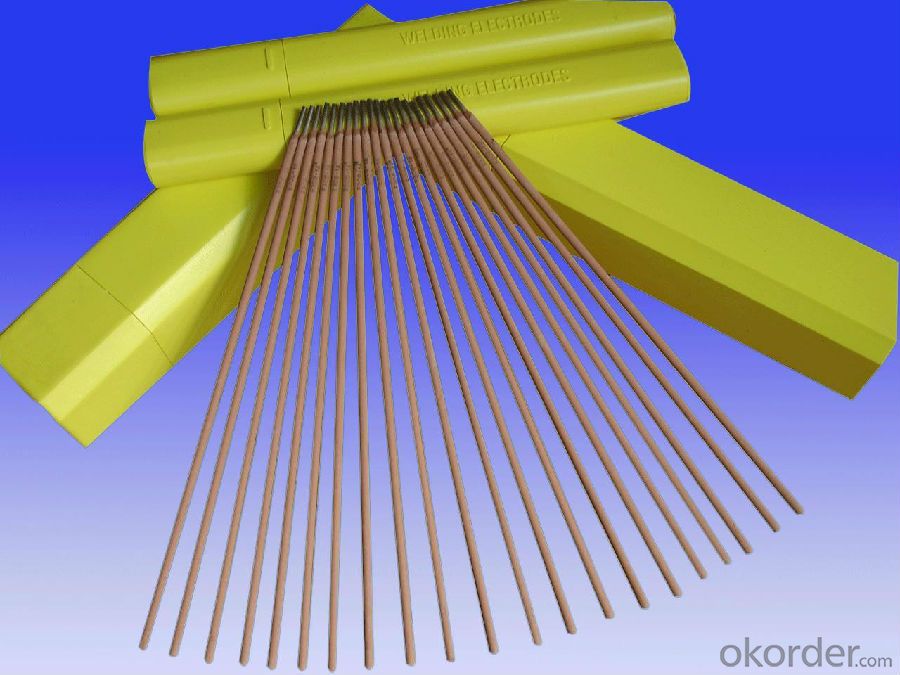

Pictures:

- Q:Can stainless steel wire be used for wire cloth?

- Yes, stainless steel wire can be used for wire cloth. Stainless steel wire is a popular choice for making wire cloth due to its excellent strength, durability, and corrosion resistance properties. Wire cloth, also known as wire mesh, is a versatile material used in a wide range of applications such as filtration, separation, reinforcement, and protection. Stainless steel wire is known for its high tensile strength, which makes it ideal for creating wire cloth with different mesh sizes and patterns. Additionally, stainless steel wire is resistant to rust and corrosion, ensuring that the wire cloth will maintain its performance and appearance even in harsh or corrosive environments. Overall, stainless steel wire is a reliable and suitable material for the production of wire cloth.

- Q:Is stainless steel wire recyclable?

- Yes, stainless steel wire is recyclable.

- Q:Is stainless steel wire easy to weld?

- Stainless steel wire can be easily welded, as it possesses excellent weldability owing to its low thermal conductivity and high melting point. These attributes facilitate a stable and controlled welding procedure. Moreover, stainless steel wire exhibits good ductility, enabling it to be effortlessly shaped and maneuvered throughout the welding operation. Nevertheless, it is essential to emphasize that the utilization of appropriate welding techniques and equipment is imperative in order to attain top-notch welds with stainless steel wire.

- Q:What are the different wire surface finishes available for stainless steel wire?

- Stainless steel wire offers various options for surface finishes, each with its own unique characteristics and advantages. Some commonly used finishes include the following: 1. Bright Annealed: This finish involves heating the wire to high temperatures and then rapidly cooling it, resulting in a surface that is bright and reflective. It offers excellent resistance to corrosion and is often preferred for applications where aesthetics play a crucial role, such as jewelry and architectural projects. 2. Pickled: To achieve this finish, the wire is immersed in an acid bath, which effectively removes impurities and oxides from the surface. The result is a clean and smooth wire, ideal for applications that require high levels of cleanliness, such as medical devices and food processing equipment. 3. Electro-Polished: This finish involves subjecting the wire to an electrolytic process that removes a thin layer of material from the surface, leaving it smooth and shiny. Electro-polished wire offers enhanced corrosion resistance and is commonly used in industries like pharmaceuticals, semiconductors, and biotechnology. 4. Passivated: To achieve this finish, the wire is treated with an oxidizing agent, such as nitric acid, to eliminate contaminants and create a protective oxide layer on the surface. Passivation enhances the wire's corrosion resistance and is often favored for marine or outdoor applications. 5. Satin: This finish is achieved by mechanically polishing the wire surface using abrasive materials, resulting in a brushed or satin-like appearance. It provides a decorative finish and is commonly used in furniture, automotive trims, or kitchen appliances. 6. Coated: This finish involves applying a protective coating, such as nylon or PVC, to the wire's surface. It offers additional protection against abrasion, chemicals, or moisture and is commonly used in applications where the wire may be exposed to harsh environments or requires insulation. These examples illustrate the range of surface finishes available for stainless steel wire. The choice of finish depends on specific application requirements, including corrosion resistance, aesthetics, cleanliness, or functionality. Consulting with a wire manufacturer or supplier can help determine the most suitable finish for a particular application.

- Q:What is drawing stainless steel, with ordinary light stainless steel what is the difference?

- Stainless steel, corrosion resistance of stainless steel with increased carbon content decreased, therefore, the carbon content of most stainless steel are relatively low, the maximum of no more than 1.2%, some steel Wc (carbon) or even less than 0.03% (such as 00Cr12). The main alloying element in stainless steel is Cr (chromium), which is corrosion resistant only when the Cr content reaches a certain value. Therefore, stainless steel in general Cr (chromium) content of at least 10.5%. Stainless steel also contains Ni, Ti, Mn, N, Nb, Mo, Si, Cu and other elements.

- Q:How can stainless steel and copper wire be welded?

- If it can be used for brazing, silver based solder solder with high temperature for welding of copper and stainless steel, but this is the need for flame welding, but if it is the relatively thin copper wire should be used with caution, so as not to burn the wire.

- Q:What are the different types of stainless steel wire ropes?

- There are several different types of stainless steel wire ropes available, each with its own unique properties and characteristics. 1. 1x19 Construction: This type of wire rope consists of 19 individual strands twisted together to form a single strand. It offers excellent strength and durability, making it suitable for applications that require high tensile strength, such as marine rigging or structural cables. 2. 7x7 Construction: This wire rope is made up of 7 individual strands, each with 7 wires twisted together. It provides good flexibility and is commonly used in applications like garage door cables, sailboat rigging, or cable railing. 3. 7x19 Construction: Similar to the 7x7 construction, this wire rope is made up of 7 strands, but each strand is composed of 19 wires twisted together. It offers increased flexibility and is often used in applications that require bending or looping, such as winch lines or crane cables. 4. 6x36 Construction: This type of wire rope consists of 6 outer strands and a center core, with each strand containing 36 wires. It provides excellent flexibility and resistance to abrasion, making it suitable for applications like hoisting or towing. 5. 6x19 Construction: With 6 outer strands and a center core, this wire rope has 19 wires twisted together in each strand. It offers good flexibility and is commonly used in applications like elevators, ski lifts, or suspension bridges. 6. 6x7 Construction: This wire rope is made up of 6 outer strands and a center core, with each strand containing 7 wires twisted together. It provides good flexibility and is often used in applications like garage door cables or stage rigging. Each type of stainless steel wire rope has its own specific strengths and uses, and it is important to select the one that best suits the requirements of your specific application.

- Q:What are the common uses of stainless steel wire in the water treatment industry?

- Stainless steel wire is widely used in the water treatment industry for various purposes. One common use is in the construction of filtration systems. Stainless steel wire mesh screens are commonly used to separate solid particles from water during the filtration process. The high corrosion resistance of stainless steel ensures that the wire does not deteriorate when exposed to water or chemicals, making it ideal for long-term use in water treatment facilities. Another use of stainless steel wire in the water treatment industry is for the production of filter cartridges. These cartridges are used to remove impurities and contaminants from water. The flexibility and strength of stainless steel wire enable the production of durable and efficient filter cartridges that can withstand high pressure and maintain their shape and integrity over time. Moreover, stainless steel wire is also used in the construction of water treatment equipment such as pumps and valves. These components require materials that can withstand the harsh conditions of water treatment processes, including exposure to chemicals, high temperatures, and pressure. Stainless steel wire provides the necessary strength, corrosion resistance, and durability for these applications, ensuring the reliable and efficient operation of water treatment systems. In addition to these uses, stainless steel wire is also employed in the production of screens for intake structures and water intakes. These screens prevent debris, algae, and other unwanted materials from entering water treatment facilities, thereby protecting the equipment and ensuring the efficiency of the treatment process. Overall, stainless steel wire is a versatile and essential material in the water treatment industry. Its corrosion resistance, durability, and strength make it suitable for a wide range of applications, including filtration systems, filter cartridges, equipment construction, and intake screens. By utilizing stainless steel wire, the water treatment industry can ensure the effective and efficient treatment of water, contributing to the provision of clean and safe water for various purposes.

- Q:Can stainless steel wire be used for making springs?

- Yes, stainless steel wire can be used for making springs. Stainless steel is a popular choice for spring manufacturing due to its excellent corrosion resistance, high tensile strength, and good elasticity. These properties make stainless steel springs suitable for a wide range of applications, including automotive, aerospace, medical devices, and industrial equipment. Additionally, stainless steel springs are known for their durability and longevity, making them a reliable choice for various spring applications.

- Q:Can stainless steel wire be used for woven wire mesh?

- Yes, stainless steel wire can be used for woven wire mesh. Stainless steel is a popular choice for woven wire mesh due to its durability, corrosion resistance, and strength. The wire is woven together in a crisscross pattern to create a mesh-like structure that can be used in a variety of applications such as filtration, screening, fencing, and many others. Stainless steel wire mesh offers excellent tensile strength, high temperature resistance, and is highly resistant to rust and corrosion. It is also available in various grades and mesh sizes, making it suitable for a wide range of industrial and commercial uses.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Carbon Welding Electrode /Titanium Welding

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 100 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords