Carbon Structural Steel Square Bars SAE1020CR

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 120000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Carbon Structural Steel Square Bars SAE1020CR

Product Specification

1, Chemical Composition %

| Grade | C | Si | Mn | S | P | Cr | Ni | Cu |

| SAE1020CR | 0.17-0.24 | 0.17-0.37 | 0.35-0.65 | ≤0.035 | ≤0.035 | ≤0.25 | ≤0.25 | ≤0.25 |

2, Mechanical Properties

| Strength of Extension σb | Yield Strength σs | Elogation δ5 | Reduction of Area ψ | Hardness (no heat treatment) |

| ≥410(42) Mpa | ≥245(25) Mpa | ≥25 % | ≥55 % | ≤156HB |

Application

1, can be used to produce various types of rivet, bolts and welding structural parts.

2, can be used to produce seamless pipes, mold, steel plate, U-steel and joist steel

Product Main Points

1, high quality with competitive price

2, certifictes are available

3, heat treatment specification: tempering, 910 ℃, air cooling

4, heat treat ment: normalizing, annealing, tempering, quenching

5, surface treatment: black, polished, galvanized

6, hot rolled, cold drawn, forged

FAQ

1, Payment Terms:

30% T/T deposit & 70% T/T before delivery.

Irrevocable L/C at sight

2, Trade Terms:

EXW, FOB, CIF, CNF

3, Delivery Time:

Normally 30-40 days. According to quantity.

4, Manufacture or Trading Company:

CNBM is a state-owned fortune global 500 trading company. We have intergrated supply system.

There are about 20 overseas locations in different countries.

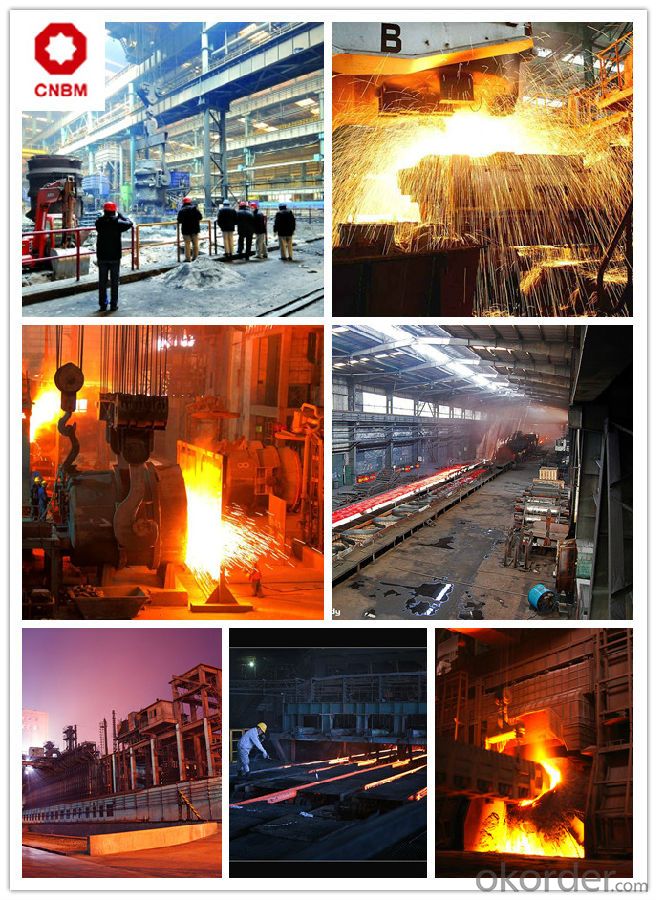

Product Show

Work Shop

About Us

- Q:What are the different types of steel round bars used in the automotive aftermarket?

- There are several different types of steel round bars commonly used in the automotive aftermarket. These include: 1. Carbon Steel Round Bars: Carbon steel is a commonly used material in the automotive industry due to its high strength and durability. It is often used in applications that require heavy-duty performance, such as suspension components, drive shafts, and steering linkages. 2. Alloy Steel Round Bars: Alloy steel is a type of steel that has been alloyed with other elements to enhance its mechanical properties. It is commonly used in the automotive aftermarket for applications that require high strength, such as crankshafts, camshafts, and axles. 3. Stainless Steel Round Bars: Stainless steel is known for its corrosion resistance and aesthetic appeal. It is often used in automotive aftermarket applications that require resistance to harsh environments, such as exhaust systems, trim components, and decorative elements. 4. Tool Steel Round Bars: Tool steel is a type of high-carbon steel that is specifically designed for tooling and machining applications. It is commonly used in the automotive aftermarket for manufacturing specialized tools, dies, and molds. 5. Bearing Steel Round Bars: Bearing steel is a type of high-carbon steel that is specifically designed for bearing applications. It is commonly used in the automotive aftermarket for manufacturing bearings and other rotating components. These are just a few examples of the different types of steel round bars used in the automotive aftermarket. The specific type of steel chosen for a particular application will depend on factors such as the required strength, durability, and corrosion resistance.

- Q:Can steel round bars be used in the manufacturing of springs?

- Indeed, the utilization of steel round bars in the production of springs is possible. Steel, being a prevalent material in spring manufacturing, is favored for its remarkable attributes including remarkable strength, endurance, and flexibility. By employing diverse manufacturing techniques like hot rolling, cold drawing, or machining, steel round bars can be skillfully transformed and molded into the desired spring shape. The selection of the precise type of steel round bar relies on the application and specific characteristics sought after for the spring, such as the desired level of rigidity or resilience. All in all, steel round bars are extensively employed and deemed as a dependable option for spring production.

- Q:What is the cost of steel round bars compared to other materials?

- The price of steel round bars can differ depending on various factors, including the grade of steel, the bar's size and dimensions, and market conditions. However, in general, steel round bars are usually more economical than other materials commonly used in construction and manufacturing. For example, when compared to materials like aluminum or titanium, steel round bars are typically more affordable. Steel is widely available, making it a cost-efficient choice for many applications. Additionally, steel possesses excellent strength and durability attributes, making it a preferred material for structural purposes. In contrast to materials like wood or plastic, steel round bars may be initially more costly. Nevertheless, when considering the long-term advantages such as its longevity, resistance to corrosion, and minimal maintenance requirements, steel still provides a cost-effective solution. It is important to note that the price of steel round bars can significantly vary depending on market conditions, including the availability of raw materials and the demand for steel products. Additionally, specialized or high-grade steel alloys may come at a higher cost due to their specific properties or manufacturing processes. To summarize, steel round bars generally offer a cost-effective option compared to many other materials used in construction and manufacturing. However, it is always advisable to research current market prices and consider specific project requirements before making any final cost assessments.

- Q:Are steel round bars suitable for use in food processing equipment?

- No, steel round bars are not suitable for use in food processing equipment. Food processing equipment requires materials that are resistant to corrosion, easy to clean, and non-reactive with food substances. While steel round bars are strong and durable, they are prone to rust and can contaminate food with metallic particles. Stainless steel, on the other hand, is the ideal choice for food processing equipment due to its high resistance to corrosion, easy cleanability, and non-reactive properties. It is important to prioritize the safety and hygiene of food processing equipment, and therefore, steel round bars should not be used in this context.

- Q:What are the options for joining steel round bars?

- There are several options for joining steel round bars, including welding, using mechanical fasteners such as bolts or screws, and adhesive bonding. The choice of method depends on factors such as the specific application, desired strength and durability, and available resources.

- Q:Can steel round bars be used in the manufacturing of marine propellers?

- Yes, steel round bars can be used in the manufacturing of marine propellers. Steel is a commonly used material in the marine industry due to its high strength, durability, and corrosion resistance. Steel round bars can be machined and shaped into the desired propeller design, providing the necessary strength and stability required for marine applications. Additionally, steel can withstand the harsh conditions of saltwater environments, making it suitable for use in marine propellers.

- Q:How do you determine the straightness of a steel round bar?

- To determine the straightness of a steel round bar, there are several methods that can be used. One common method is visual inspection, where the bar is carefully examined for any visible bends, twists, or deviations from a straight line. This can be done by placing the bar on a flat surface and checking for any gaps or unevenness between the surface and the bar. Another method is to use a straightedge or a precision ruler. By placing the straightedge or ruler along the length of the bar, any deviations from a straight line can be easily detected. This method allows for more precise measurements and can help identify even slight bends or curves. Measuring devices such as dial indicators or laser alignment tools can also be used to determine the straightness of a steel round bar. These devices provide more accurate measurements and can quantify the degree of straightness by providing numerical readings of any deviations from a straight line. It is important to note that the acceptable level of straightness may vary depending on the specific application or industry standards. In such cases, specific tolerances or guidelines may need to be followed to ensure that the steel round bar meets the required straightness criteria. Overall, determining the straightness of a steel round bar requires careful visual inspection and the use of appropriate measuring tools to ensure that it meets the necessary straightness standards for its intended use.

- Q:What are the typical price ranges for steel round bars?

- The typical price ranges for steel round bars vary depending on factors such as the diameter, length, grade, and market conditions. However, generally speaking, the price range for steel round bars can range from $0.50 to $3 per pound or more.

- Q:How do you determine the straightness of a steel round bar?

- There are several methods available to determine the straightness of a steel round bar. One commonly used technique involves visually inspecting the bar for any visible bends, twists, or deviations from a straight line. This involves placing the bar on a flat surface and checking for gaps or unevenness between the bar and the surface. Another method involves utilizing a straightedge or precision ruler. By placing either of these tools along the length of the bar, any deviations from a straight line can be easily detected. This method allows for more precise measurements and can even identify slight bends or curves. Alternatively, measuring devices like dial indicators or laser alignment tools can be employed to assess the straightness of a steel round bar. These devices provide more accurate measurements and can quantify the degree of deviation from a straight line by providing numerical readings. It should be noted that the acceptable level of straightness may vary depending on the specific application or industry standards. In such cases, it may be necessary to adhere to specific tolerances or guidelines to ensure that the steel round bar meets the required straightness criteria. In conclusion, determining the straightness of a steel round bar necessitates careful visual inspection and the utilization of appropriate measuring tools to ensure that it satisfies the necessary straightness standards for its intended purpose.

- Q:What are the different tolerances for steel round bars?

- Steel round bars have a range of tolerances that are determined by the specific requirements and standards of different industries and applications. These tolerances ensure that the dimensions and surface conditions of the bars meet the desired specifications. The diameter tolerance is the most common tolerance for steel round bars. It refers to the allowable deviation from the specified diameter. For example, a steel round bar with a diameter tolerance of +/- 0.005 inches means that the actual diameter can vary within this range. Another important tolerance is the straightness tolerance, which measures the allowable deviation from a straight line over a specified length of the bar. Straightness tolerances are usually expressed as the maximum deviation in relation to the length, such as 0.010 inches per foot. Surface finish tolerance is also crucial and refers to the acceptable variation in the surface texture or roughness of the bar. This tolerance is often specified using parameters like Ra or Rz. For instance, a surface finish tolerance of Ra 0.8 micrometers means that the average roughness should not exceed this value. In addition to these common tolerances, there may be other specific tolerances based on the intended application of the steel round bars. These can include tolerances for straightness, length, weight, or other dimensional properties. It's important to note that the tolerances for steel round bars can vary depending on the standards followed by different industries and countries. To determine the specific tolerances required for a particular application, it's advisable to refer to the relevant standards or specifications.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Carbon Structural Steel Square Bars SAE1020CR

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 120000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords