Carbon Structural Steel Square Bars S20C

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 400 m.t

- Supply Capability:

- 80000 m.t/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

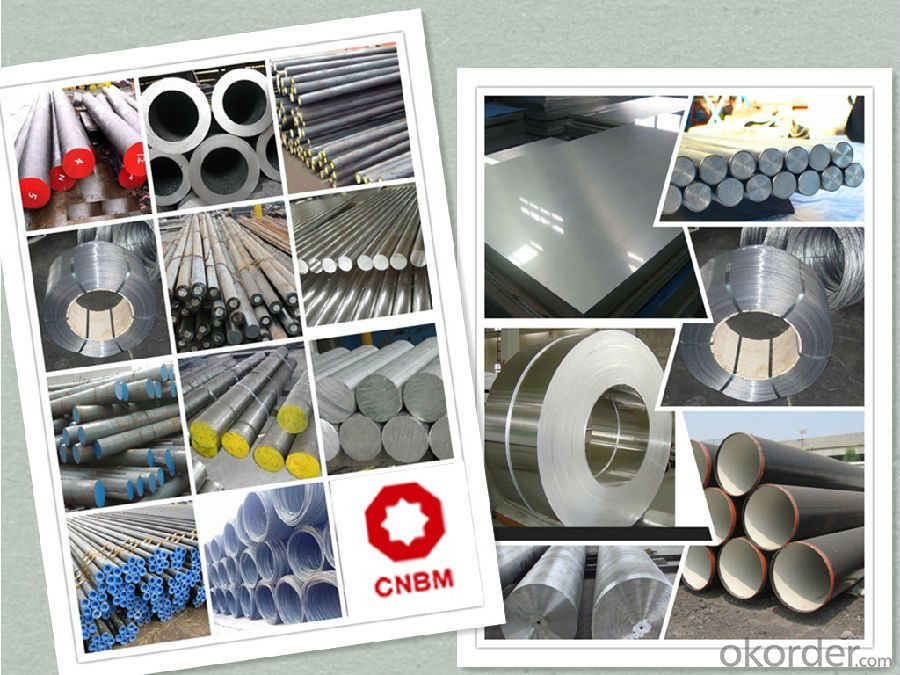

Carbon Structural Steel Square Bars S20C Specification 1, Size: 120*120mm; 130*130mm; 150*150mm; 160*160mm; 200*200mm 2, Length: Max 12m 3, Heat Treatment: Normalizing, Annealing, Tempering, Quenching 4, Surface Treatment: Black, Polished, Galvanized Application 1, Used in the manufacturing mechanical parts with high toughness but can not suffer great stress 2, Used in manufacturing carburizing and carbonitriding parts with high surface hardness. Chemical Composition % Products Show C Si Mn P S Cr Ni Cu 0.08-0.23 0.15-0.35 0.30-0.60 ≤0.030 ≤0.035 ≤0.20 ≤0.25 ≤0.25

Work Shop

About Us

- Q:Can a steel square be used for checking the squareness of cabinets?

- Indeed, cabinets can have their squareness checked by employing a steel square. In woodworking and carpentry, it is quite customary to utilize steel squares to ensure the correctness of right angles and ascertain squareness. Through the act of positioning the steel square adjacent to the cabinet's corners, one can effortlessly determine whether the cabinet is correctly square or necessitates some modifications. The straight edges of the steel square furnish a dependable benchmark for examining the squareness of cabinets and guaranteeing their appropriate alignment.

- Q:Can a steel square be used for measuring door and window openings?

- Yes, a steel square can be used for measuring door and window openings. Its right angles and various markings make it a versatile tool for determining accurate measurements and ensuring proper fit for doors and windows.

- Q:How do you use a steel square to determine the slope of a garden fence?

- To determine the slope of a garden fence using a steel square, you would first place one edge of the square against the ground at the base of the fence post. Then, align the other edge of the square with the fence post, ensuring it remains vertical. By checking the level on the steel square, you can determine if the fence post is leaning or if it is straight. This will help you assess the slope of the garden fence.

- Q:Can a steel square be used for checking the alignment of a door frame?

- Yes, a steel square can be used for checking the alignment of a door frame. It can be used to ensure that the corners of the door frame are square and that the sides are perpendicular.

- Q:Can a steel square be used for checking the squareness of a foundation?

- Checking the squareness of a foundation can be accomplished with the use of a steel square. In the field of carpentry and construction, a steel square is a versatile tool that is frequently employed for the purpose of verifying and marking right angles. Comprised of two arms connected at a 90-degree angle, one of these arms being longer than the other, the steel square is an effective instrument. When the longer arm is placed against a straight edge of the foundation and the shorter arm is aligned with another edge, it becomes possible to determine whether the foundation is square or not. If the angles formed measure 90 degrees, then the foundation is indeed square. However, it is crucial to acknowledge that when dealing with larger foundations or when a higher degree of precision is required, more accurate tools such as laser levels or transit levels may be employed in conjunction with the steel square.

- Q:How do you use a steel square to find angles for compound bevel cuts?

- To use a steel square to find angles for compound bevel cuts, you need to follow a few steps: 1. Understand the concept: Compound bevel cuts involve two angles that need to be set correctly to achieve the desired cut. These angles are typically referred to as the miter angle and the bevel angle. 2. Set the miter angle: The miter angle determines the horizontal angle of the cut. To find this angle, place the steel square against the edge of the workpiece and align it with the desired miter angle. Make sure the long edge of the square is parallel to the edge of the workpiece. 3. Mark the miter angle: Once the steel square is aligned, use a pencil or a marking knife to mark the edge of the workpiece using the long edge of the square as a guide. This mark represents the miter angle for your compound bevel cut. 4. Determine the bevel angle: The bevel angle determines the vertical angle of the cut. To find this angle, place the steel square against the face of the workpiece and align it with the desired bevel angle. Ensure that the short edge of the square is perpendicular to the face of the workpiece. 5. Mark the bevel angle: Once the steel square is aligned, use a pencil or a marking knife to mark the face of the workpiece using the short edge of the square as a guide. This mark represents the bevel angle for your compound bevel cut. 6. Adjust your tools: With the miter and bevel angles marked, you can now adjust your tools accordingly. Depending on the type of compound bevel cut you are making, you may need to adjust the miter gauge on a table saw or the bevel angle on a compound miter saw. 7. Make the cut: Once your tools are properly set, carefully position the workpiece according to the marked angles and make the compound bevel cut, ensuring safety precautions are taken. Remember, practice and precision are key when working with compound bevel cuts. It's always a good idea to double-check your angles and make test cuts on scrap material before working on your final project.

- Q:How much is the thick wall hollow square 30*30

- Steel is an important material for national construction and the realization of the four modernization indispensable, wide application, wide variety, according to the different steel profile is generally divided into sections and plates, pipes and metal products four categories, in order to facilitate the organization of steel production, supply and improve order management, and divided into heavy rail, light rail, large steel, and steel, small steel, steel cold-formed steel, high-quality steel, wire rod, steel plate, steel sheet, electrical silicon steel sheet, strip steel, seamless steel pipe, welded steel pipe, steel, metal products and other varieties.

- Q:What are some common uses for a steel square in cabinetry?

- A steel square is commonly used in cabinetry for various tasks such as measuring and marking right angles, checking the squareness of corners, laying out or marking lines for cuts, and ensuring accurate and precise installations.

- Q:Can a steel square be used for checking the squareness of a picture frame corner?

- Checking the squareness of a picture frame corner with a steel square is not ideal. Although a steel square is commonly used in carpentry and construction, it may not be practical or accurate for this purpose. Picture frames are typically smaller and a steel square may be too large and cumbersome. Moreover, picture frames often have decorative elements or beveled edges that may not align perfectly with a steel square. It is advisable to use a specialized tool like a framing square or a precision square specifically designed for checking picture frame corners. These tools are smaller, more precise, and better suited for this task.

- Q:Are there any alternative tools to a steel square for measuring angles?

- Yes, there are several alternative tools to a steel square for measuring angles. Some examples include protractors, bevel gauges, digital angle finders, and angle measuring apps on smartphones. Each tool has its own advantages and may be more suitable for specific situations or preferences.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Carbon Structural Steel Square Bars S20C

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 400 m.t

- Supply Capability:

- 80000 m.t/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords