Carbon Steel Plate SA516 Gr 60 with High Quality

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 1111 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1、Structure of Carbon Steel Plate SA516 Grade 60 Description:

Carbon Steel Plate SA516 Grade 60 is an ideal steel for use in moderate to lower working temperatures. Carbon Steel Plate SA516 Grade 60 is used in the fabrication of weldable industrial boilers and steel pressure vessels. It is a normalized steel which is known for its excellent notch toughness and weldability and is primarily found in pressurised service throughout the oil, gas and petrochemical industry.

2、Main Features of the Carbon Steel Plate SA516 Grade 60:

• High manufacturing accuracy

• High strength

• Small inertia resistance

• Strong heat dissipation ability

• Good visual effect

•Reasonable price

3、Hot Rolled Carbon Steel Plate Images:

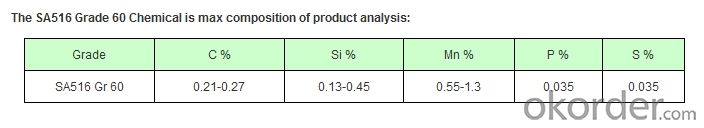

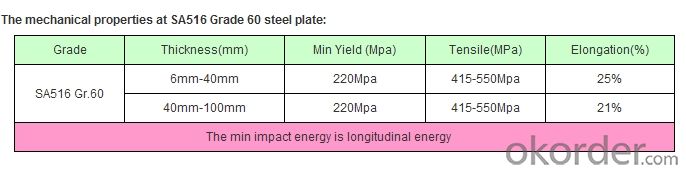

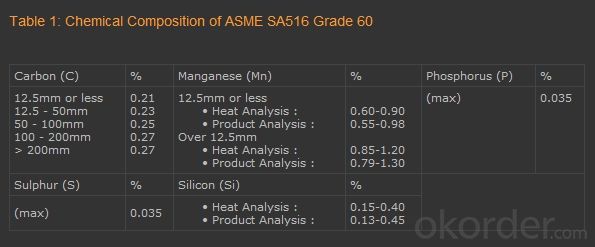

4、Carbon Steel Plate SA516 Grade 60 Specification:

| Grade: | S235jr S275jr S355jrSS400 Q235 Q345 ASTM A36 |

| Thickness: | 1.8-100mm |

| Width: | 1000-2500mm |

| Length: | 2000-12000mm as request |

| Mill: | qualified steel mill in China |

| Bundle weight: | max 4mt or as request |

| Package: | seaworthy packing ( bared with steel strips) |

5、FAQ of Hot Rolled Carbon Steel Plate:

①How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

②How long can we receive the product after purchase?

In the purchase of product within three working days, We will arrange the factory delivery as soon as possible. The pecific time of receiving is related to the state and position of customers.

③ How can we get more information?

You can contact us by Email or call us directly and we will do our best to give you valuable information as much as possible but this service is not available on weekends.

- Q:Can the steel sheets be bent without cracking?

- Steel sheets have the capability to be bent without cracking. This capability relies on several factors including the type and grade of steel, the thickness of the sheet, and the bending process employed. As a general rule, steel sheets can be bent without cracking as long as the bending radius and angle fall within the recommended limits specific to the type and grade of steel being used. Furthermore, preheating the steel sheet before bending can further mitigate the risk of cracking. It is crucial to adhere to proper bending techniques and utilize suitable tools to guarantee successful bending of steel sheets without any cracks.

- Q:What's the difference between hot-rolled seamless steel tube and cold-rolled seamless steel tube?

- Cold rolled seamless steel pipe (DIAL) in general, steel pipe for low and medium pressure boiler tube, high-pressure boiler steel pipe, alloy steel pipe, stainless steel pipe, oil cracking tube and other steel tube, including carbon thin-walled steel, alloy thin-walled steel, stainless steel, thin steel tube.

- Q:What is the difference between plain carbon steel sheet and stainless steel sheet?

- Plain carbon steel sheet and stainless steel sheet are both types of steel sheets, but they have several distinct differences. The main difference between plain carbon steel sheet and stainless steel sheet lies in their composition and properties. Plain carbon steel sheet is primarily made up of iron and carbon, with small amounts of other elements such as manganese and silicon. It is known for its strength and durability, making it suitable for a wide range of applications. However, plain carbon steel is prone to rust and corrosion when exposed to moisture or certain chemicals. On the other hand, stainless steel sheet is made up of iron, carbon, and a minimum of 10.5% chromium. This addition of chromium forms a protective layer on the surface of the steel, known as a passive film, which prevents corrosion and rusting. Stainless steel is highly resistant to stains, heat, and corrosion, making it ideal for applications where hygiene and durability are crucial, such as in the food and medical industries. Another significant difference between the two types of steel sheets is their appearance. Plain carbon steel sheet has a dull grey finish, while stainless steel sheet has a shiny, reflective surface. This aesthetic difference is often a consideration in industries where the visual appeal of the material is important, such as architectural or interior design applications. Furthermore, stainless steel sheet has a higher price point compared to plain carbon steel sheet. This is due to the additional alloying elements, such as chromium and nickel, which are added to enhance its corrosion resistance and other properties. The higher cost of stainless steel is often justified by its superior performance and longevity in corrosive environments. In summary, the key differences between plain carbon steel sheet and stainless steel sheet are their composition, properties, appearance, and price. Plain carbon steel is strong but prone to rust, while stainless steel is corrosion-resistant and has a shiny finish. The choice between the two depends on the specific requirements of the application, including the need for corrosion resistance, aesthetics, and budget.

- Q:What does "Z" mean to the performance of steel?

- Z to the plate, also known as "Z" to steel, also known as "lamellar steel tearing resistant steel", that is usually referred to as Z performance.The use of welded connections in steel structure, when the sheet thickness of not less than 40 mm and bear along the thickness direction of the tension, to avoid lamellar tearing when welding, the lamellar tearing of steel (commonly referred to as the "Z to steel"). There is a lamellar tearing problem in thick plates, so Z performance test is necessary.

- Q:Are the steel sheets suitable for architectural applications?

- Yes, steel sheets are suitable for architectural applications. Steel is a versatile material that offers several advantages for architectural purposes. It is strong, durable, and can withstand harsh weather conditions, making it ideal for various architectural elements such as roofing, cladding, and facades. Steel sheets also offer design flexibility, allowing architects to create unique and innovative structures. Additionally, steel is a sustainable material as it is recyclable and has a long lifespan, making it an environmentally friendly choice for architectural applications. Overall, steel sheets are a reliable and versatile option for architects looking to incorporate structural integrity, aesthetic appeal, and sustainability into their designs.

- Q:What is the average weight of steel sheets per square foot?

- The average weight of steel sheets per square foot can vary depending on the thickness and type of steel being used. However, as a general guideline, the weight of mild steel sheets can range from 40 to 100 pounds per square foot. Thicker and heavier steel sheets, such as those used in construction or industrial applications, can weigh up to 200 pounds or more per square foot. It is important to note that these weights are approximate and may vary depending on the specific specifications of the steel sheet.

- Q:What is the average lifespan of painted steel sheets?

- Painted steel sheets can have varying lifespans depending on factors such as paint quality, usage environment, and maintenance levels. Generally, their lifespan ranges from 15 to 25 years. This estimate is based on proper installation, regular inspections for damage or corrosion, and necessary touch-up or maintenance work. It is worth noting that exposure to severe weather, chemicals, and physical damage can significantly affect the lifespan of painted steel sheets. To go beyond the average range, regular maintenance and appropriate care are essential.

- Q:What is the process of manufacturing steel sheets?

- The process of manufacturing steel sheets involves several steps. First, iron ore is extracted from the ground and processed to remove impurities. This iron ore is then smelted in a blast furnace, along with coke and limestone, to produce molten iron. The molten iron is further refined in a basic oxygen furnace or an electric arc furnace to remove any remaining impurities and adjust the desired composition. Once the iron has been refined, it is converted into steel by adding alloying elements such as carbon, manganese, and other elements as required. The molten steel is then cast into large slabs or ingots. These slabs are reheated and passed through rolling mills to reduce their thickness and shape them into long, flat sheets. The sheets are then cooled, coated or treated as necessary, and cut into desired sizes before being packaged and shipped for various applications.

- Q:Are steel sheets suitable for mining or construction equipment?

- Yes, steel sheets are highly suitable for mining and construction equipment due to their strength, durability, and resistance to wear and tear. Steel sheets provide excellent structural integrity, making them capable of withstanding heavy loads, harsh working conditions, and extreme weather. Additionally, steel sheets can be easily fabricated and customized to meet the specific requirements of mining and construction equipment, making them a preferred choice in these industries.

- Q:Can steel sheets be used for food processing or storage?

- Yes, steel sheets can be used for food processing or storage. Steel is a durable and hygienic material that is commonly used in the food industry due to its resistance to corrosion, easy cleaning, and ability to maintain proper food safety standards.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Carbon Steel Plate SA516 Gr 60 with High Quality

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 1111 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords