Carbon Steel Pipe Fittings Butt-Welding Concentric Reducers

- Loading Port:

- Dalian

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Steel Pipe Fittings Butt-Welding Concentric reducers

Features standards and products of our Butt-Welding Concentric reducers:

Features of Butt-Welding Concentric reducers:

1. High class materials

Our products only use high class raw materials of carbon/alloy steel pipes made from NKK or MANNESSMANN equipment for ordinary, high pressure, low/high temperature,boiler and other purposes.

2. Uniform wall thickness and perfectly round

This can be achieved by our particular technical knowhow and our quality control program.

3. Accurate dimension

Efficient piping work can be made only with fittings of correct dimensions and shapes. Our fittings are finished to have accurate straight/ plane ends, beveled angle...etc. to applicable standards by means of two or three spindle beveling machines.

Standards of Butt-Welding Concentric reducers:

Our welding fittings are manufactured in compliance with the following appliance standards:

ASME B16.9 ASTM A234 MSS-SP43 WPHY60 JIS B2311 DIN2605

ASTM A403 MSS-SP75 WPHY65 JIS B2312 DIN2606

ASTM A420 WPHY42 WPHY70 JIS B2313 DIN2616

ASTM A860 WPHY52 DIN2615

Manufacturing method and process of Butt-Welding Concentric reducers:

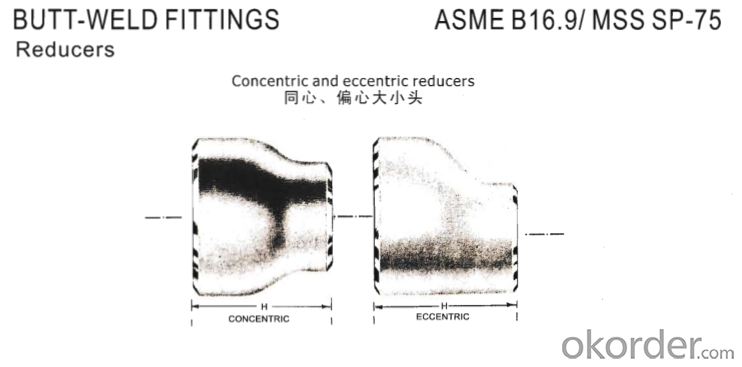

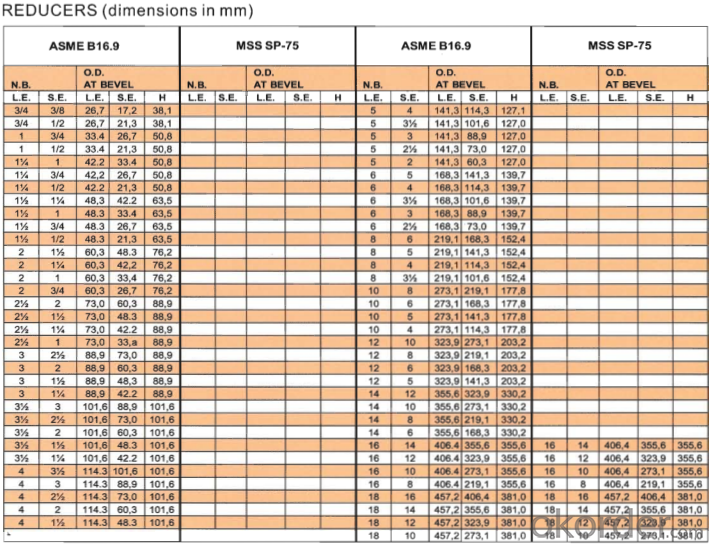

BUTT-WELD FITTINGS ASME B16.9/MSS SP-75

Butt-Welding Concentric reducers:

Packing of Butt-Welding Concentric reducers:

FAQ of Butt-Welding Concentric reducers:

1) Q: What’s your main product? Which kinds of products are more competitive in your product range?

A: Our main products are steel flanges, pipe fittings and steel pipes.

Competitive Items: flanges in stainless steel, carbon steel, alloy steel and punching carbon steel

Butt welded pipe fittings in stainless and carbon steel

2) Q: what’s your largest size of flange and fitting? How long is the production cycle?

A: The largest flange we could produce is 80’’ and the largest fitting is 50’’.

In general, we spend 20-25 days in a 20-ton order. If necessary, we could make it shorter.

3) Q: Could you produce according to the drawings?

A: Sure. We could produce according to the provided drawings, which include forged and casted items.

4) Q: What kind of certificates do you have?

A: We have ISO, TUV, API,SGS,BV etc. fittings in stainless and carbon stee

Malleable Iron ,Stainless and carbon steel pipes

- Q:Is there special jackets For You when You become a weather spotter? And if any of You are a weather spotter, what do i need to know before i go to classes?

- u shouldnt care wat they think. get it. theyre just being stupid

- Q:I am using Avery (product number 18660) address labels and I am doing everything right in Word 2007 in order to print them out. Once I start printing them, the addresses print all the way towards the top and they shouldn't be. The margins are already set correctly because when I printed it on regular white paper, it did so correctly. WHY IS IT DOING THIS?! Let me know what I can do to fix this. THANKS!!!

- Always discard disposable gloves after they're use.

- Q:What are the reducing, reducing, reducing, etc in the pipe joint?. How do they tell each other what they call that?. Seek expert advice

- The pipe joint is divided into cylindrical pipe thread and tapered pipe thread, and the change of diameter refers to the different diameters of the two ends of the pipe joint

- Q:I'm just baught a new LCD TV and i have two wires in each outlet. I want to ground this specific outlet by running a wire to a cold water pipe. What gage wire should i use.

- It That has several preconditions: 1) room to cut the pipe, 2) ability to move one of the cut pipes, 3) already having a repair sleeve, 4) water already shut off. If there is no ability to move either end, then a larger section needs to be cut out and two sleeves installed. This doubles the repair time. For a plumber to do it should be less than 10 minutes unless the pipe is too close. Probably you are in for a minimum service call. Depending on where you are, expect $75 to $200.

- Q:I'm looking for some UV reflective material that i can sew onto phat pants. And i cant seem to find any place that will sell them. Help plz

- For the turret mount M-2 browning HB- great anti aircraft machine gun,good stopping power For coaxial Browning 30. cal- Rapid rate of fire,not pron to jamming For bow mount Browning 30.cal- same as above

- Q:I had to use a kitchen extinguisher when food caught fire inside my stove. I'm unsure about how to clean up the residue left on the inside.

- Well, I've been parked by a tree for a little over a day now and have yet to receive a ticket. And the college I stay at have police patrol literally ever hour or two. I would say thats a silly question but I wouldn't be surprised if it is illegal somewhere. I would tell you to call your local police number and ask but they'll probably think your messing with them.

- Q:Consult the problem of the pressure at the entrance and exit of the pipe jointNow I'm in the oil system design has a 4 joint, one port as the oil inlet, the other three ports as an oil outlet, so, now oil inlet pressure is 2MPA, the oil outlet pressure is not each only 2/3=0.66MPA, because in this way, each oil outlet the flow of oil inlet flow only 1/3, the trouble which master to help me explain, I understand you talked about from the truth, I added 10 points

- Assuming that your 3 oil outlet, load is infinite, as follows, three load (cylinder or motor) are not action, three outlet pressure is 2MPa, three outlet pressure gauge pressure is 2MPa

- Q:Detailed point. I'd like to add some knowledge about it.

- The sleeve type pipe joint has the advantages of simple structure, convenient operation and no need of welding. But in the middle and high pressure hydraulic system, if improper operation, often will cause leakage, and affect its popularization and use. After years of practice, the author summed up some experience, and achieved good results.As shown in the drawings, the sleeve type pipe joint is mainly composed of a joint body 1 with a taper hole of 24 degrees, a clamping sleeve 2 with a sharp inner edge and a pressing nut 3 and three parts which are pressed. Tighten the nut 3, card set of 2 is to promote the 24 degree taper and then deformation, make the card sleeve and the connector body cone to form a spherical contact seal; at the same time, the outer wall of the inner edge of the sleeve mouth embedded on the outer wall of the steel pipe 4, a pressure ring groove, so that the reliable sealing effect. The best choice of steel tube to eliminate stress annealing 20# fine drawing pipe, so that it is beneficial to insert the inner edge of the sleeve into the outer surface of the steel pipe, and play a reliable sealing role.

- Q:these stripes were applied professionally from the factory..I am looking for away to soften the material(3M reflective) to pull this off from the paint?

- no one could possibly answer this question is it pvc or cast iron .

- Q:I want to buy a wireless door/window alarm,Can anyone recommend which one is better for the elderly and children?

- I hope you mean galvanized steel pipe, not corrugated steel pipe. Black iron pipe is used for natural gas or propane. It is OK to use galvanized steel fittings for gas, but black iron fittings are preferred. For water, only use galvanized steel pipe and galvanized fittings because black iron fittings will soon rust. Galvanization slows down the rusting process, but eventually all steel pipe will rust. I would only use copper pipe for new water plumbing.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Carbon Steel Pipe Fittings Butt-Welding Concentric Reducers

- Loading Port:

- Dalian

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products