CARBON STEEL PIPE FITTING TEE BEND FITTINGS 2''-48''

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t

- Supply Capability:

- 300 m.t/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Products Detailed Description

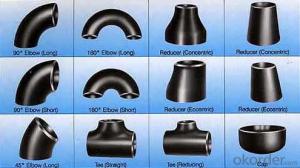

Products | pipe fittings elbows, bends,tees, reducers caps |

Size | 1/2" - 48" |

Wall thickness | Sch5-Sch160 XXS |

Standard | ANSI, ASME API5L, OCT, DIN and JIS, etc. |

we can also produce according to drawing and standards provided by customers. | |

Material | Carbon steel, alloy steel and stainless steel. |

We can produce according to materials appointed by consumers. | |

Packaging | Plywood Cases,plywood pallet, plastic bag or as customers requirement |

Surface Treatment | Shot blasted, rust-proof black oil |

Delivery Time | 10-60 days |

Quality | First grade |

Others | 1.Special design available according to your drawing. |

2.anti-corrosion and high-temperature resistant with black painting | |

3. All the production process are made under the ISO9001:2000 strictly. | |

4. A conformity rate of ex-factory inspection of products. |

Specifications

Ansi B16.9 WPB carbon steel pipe fitting elbow tee reducer

Size:Seamless 1/2"-24" Welded 1/2"-48"

ANSI B16.9 WPB carbon steel pipe fitting elbow tee reducer

1.Size: Seamless 1/2"-24" Welded 1/2"-48"

2. WT: SGP, STD, SCH40, SCH80, SCH100,SCH120,SCH160,XS,XXS

3. Material:

stainless steel Grade: 201,304,304L,316,316L,317,317L,904L,and etc

carbon steel Grade: WPB,GRB, Q235,16MN

Alloy steel: st35.8,st52,wp11,wp22,wp12 wp l6

4. Standard: ASTM/AISI/DIN/JIS

5. Type: Concentric and eccentric

6. Surface treatment: Transparent oil, rust-proof black oil

7. Applications range: Applications range: for use in the petroleum, smelting, foodstuff, power, papermaking, chemical, medical equipment,aviation, boiler heat exchanger, and other fields

8. Packing: wooden case or as per customers' requirement

- Q:Can steel pipes be used for water supply networks?

- Yes, steel pipes can be used for water supply networks. Steel pipes are commonly used in water supply systems due to their durability, strength, and resistance to corrosion. They are able to withstand high pressure and can safely transport water over long distances. Additionally, steel pipes are highly versatile and can be easily connected, making them suitable for various water supply network applications.

- Q:Can steel pipes be used for LNG terminals?

- Yes, steel pipes can be used for LNG terminals. Steel pipes are commonly used in the construction of LNG terminals due to their durability, strength, and resistance to extreme temperatures. Additionally, steel pipes can effectively handle the high-pressure requirements of LNG transportation and storage.

- Q:What is the difference between schedule 10 and schedule 40 steel pipes?

- Schedule 10 and schedule 40 steel pipes differ in terms of their wall thickness. Schedule 10 pipes have a thinner wall, making them suitable for low-pressure applications, while schedule 40 pipes have a thicker wall, making them more appropriate for high-pressure applications.

- Q:What is the role of steel pipes in the construction of bridges?

- Steel pipes play a crucial role in the construction of bridges as they are used for various purposes such as supporting the weight of the bridge, providing structural integrity, and allowing for the flow of fluids or gases. Steel pipes are often used as support columns or piles in bridge foundations, providing stability and strength to the structure. They are also used for constructing bridge piers, trusses, and beams, ensuring the bridge can withstand heavy loads and forces. Additionally, steel pipes can be utilized for the transportation of water, gas, or other fluids across the bridge, making them essential for the overall functionality and longevity of the bridge.

- Q:How are steel pipes repaired in case of damage or leaks?

- Steel pipes are repaired in case of damage or leaks by first identifying the affected area. The damaged section is then cut out, and a new piece of steel pipe is welded or bolted in its place. This ensures a secure and watertight connection, restoring the integrity of the pipe and preventing further leaks or structural issues.

- Q:Are the welded and galvanized tubes the same weight?

- The same specifications of welded pipe and galvanized pipe weight is not the same, the general welding tube weight, galvanized pipe light.

- Q:How are steel pipes classified based on their end connections?

- Steel pipes can be classified based on their end connections into three main categories: threaded, flanged, and welded. Threaded pipes have screw threads on the ends, allowing for easy assembly and disassembly. Flanged pipes have flanges on the ends, which are flat surfaces that can be bolted together, providing a strong connection. Welded pipes have their ends welded together, creating a permanent and secure joint.

- Q:Can steel pipes be used for sewage systems?

- Yes, steel pipes can be used for sewage systems. Steel pipes are commonly used in sewage systems for their durability, strength, and resistance to corrosion. They are suitable for transporting sewage and wastewater, ensuring reliable and long-lasting performance.

- Q:What is the purpose of a steel pipe coating?

- The purpose of a steel pipe coating is to provide protection to the pipe from corrosion and other environmental factors that can lead to deterioration. Coating the pipe with a layer of material helps to create a barrier between the steel and the surrounding environment, preventing direct contact and reducing the risk of corrosion. This is especially important for pipes that are used in industries such as oil and gas, water distribution, and construction, where they are exposed to harsh conditions such as moisture, chemicals, and extreme temperatures. The coating also helps to enhance the durability and longevity of the pipe, ensuring that it can withstand the demands of its intended application. Additionally, certain types of pipe coatings can also provide insulation properties, preventing heat loss or transfer in applications where temperature control is critical. Overall, the purpose of a steel pipe coating is to protect the pipe, extend its lifespan, and ensure its optimal performance in various industries and environments.

- Q:Are steel pipes suitable for wastewater treatment facilities?

- Steel pipes are indeed a suitable option for wastewater treatment facilities. These facilities commonly employ steel pipes because of their impressive strength, durability, and resistance against corrosion. Given that wastewater treatment facilities often deal with corrosive and abrasive substances, steel pipes have the ability to endure these harsh conditions. Furthermore, steel pipes come in various sizes and configurations, allowing for effortless installation and customization to meet the specific requirements of the facility. Moreover, if necessary, steel pipes can be easily repaired or replaced, ensuring the long-lasting and dependable nature of the wastewater treatment system. Ultimately, steel pipes are an appropriate choice for wastewater treatment facilities due to their strength, durability, corrosion resistance, and flexibility for installation and maintenance.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

CARBON STEEL PIPE FITTING TEE BEND FITTINGS 2''-48''

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t

- Supply Capability:

- 300 m.t/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords