Carbon Steel Hot Rolled Wire Rod SAE1008 SAE1006 SAE1018

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 40000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

OKorder is offering Carbon Steel Hot Rolled Wire Rod SAE1008 SAE1006 SAE1018 at great prices with worldwide shipping. Our supplier is a world-class manufacturer of steel, with our products utilized the world over. OKorder annually supplies products to European, North American and Asian markets. We provide quotations within 24 hours of receiving an inquiry and guarantee competitive prices.

Product Applications:

Carbon Steel Hot Rolled Wire Rod SAE1008 SAE1006 SAE1018 are ideal for structural applications and are widely used in the construction of buildings and bridges, and the manufacturing, petrochemical, and transportation industries.

Product Advantages:

OKorder's Carbon Steel Hot Rolled Wire Rod SAE1008 SAE1006 SAE1018 are durable, strong, and resist corrosion.

Main Product Features:

· Premium quality

· Prompt delivery & seaworthy packing (30 days after receiving deposit)

· Corrosion resistance

· Can be recycled and reused

· Mill test certification

· Professional Service

· Competitive pricing

Product Specifications:

Specifications of Wire Rod SAE1008B:

Steel Grade: SAE1008B Standard: ASTM, GB

Diameter: 5.5mm, 6.5mm, 7mm,8mm,9mm,10mm,12mm,14mm

Type: Drawn Wire Alloy or Not: Alloy Brand Name: N-RIVER

Technique: Hot Rolled Place of Origin: China Mainland

Chemical Composition:

Please kindly find our chemistry of our material based on SAE1008B as below for your information

Grade | Chemical Composition (%) | |||||

C | Mn | S | P | Si | B | |

SAE1008B | 0.10max | 0.32max | 0.045max | 0.040max | 0.30max | 0.0008min |

Mechanical properties | ||||||

Yield strength(N/mm2) | Tensile strength(N/mm2) | Elongation (%) | ||||

≥195 | 350-380 | ≥32 | ||||

Usage and Applications of Wire Rod SAE1008B:

After hot-rolled the products shaped into coil and delivery as finished product, including round, square, rectangular, hexagonal and so on. Since most of the products are round, it is generally called wire rod. Carbon steel wire rod is widely used in construction and manufacturing. Carbon steel wire rod is mainly used for reinforcement of reinforced concrete and welded structure or reprocessed (roberts , nail, etc.) materials, especially used to produce wire drawing, welding electrode, nails, spring, electronic, precise machinery parts and so on.

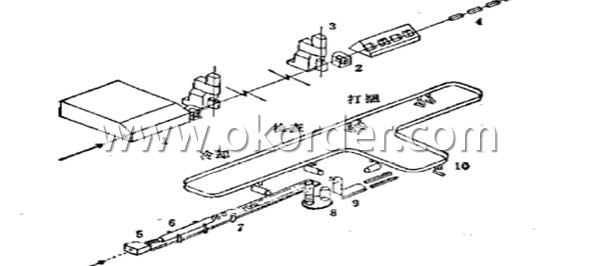

Production Process of Wire Rod SAE1008B:

1-Furnace 2-Roughing Mill 3-High-speed Finishing Mill 4-Water-cooled Device 5-Coiling Device

6-Cooling Device 7-Chain Conveyer 8-Spool Collecting Device 9-Spool Down Device 10-Hook Conveyer

Packaging & Delivery of Wire Rod SAE1008B:

Packaging Detail: products are packed in coil and then shipped by container or bulk vessel

Each coil weight: 2-3MT

Delivery Detail: within 45 days after received deposit or LC.

Label: to be specified by customer, generally, each bundle has 1-2 labels

Trade terms: CFR, CIF

Note:

1. Our products are produced according to national standard (GB), if not, supply according to national standards (GB) or agreement as customer required.

2. Other Grade and Standard carbon steel wire rod we can supply:

Grade: H08A, 30MnSi, 62B-82B

Standard: AISI, BS, JIS, DIN

The Minimum Order Quantity of these products is high, and need to be confirmed.

3. We can not only supply carbon steel wire rod; if you need anything about building materials, please contact us.

4. Please send us your detail specifications when inquire. We will reply to you as soon as possible. We sincerely hope we can establish a long stable business relationship.

FAQ:

Q1: Why buy Materials & Equipment from OKorder.com?

A1: All products offered byOKorder.com are carefully selected from China's most reliable manufacturing enterprises. Through its ISO certifications, OKorder.com adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q3: How soon can we receive the product after purchase?

A3: Within three days of placing an order, we will begin production. The specific shipping date is dependent upon international and government factors, but is typically 7 to 10 workdays.

Q4: What makes stainless steel stainless?

A4: Stainless steel must contain at least 10.5 % chromium. It is this element that reacts with the oxygen in the air to form a complex chrome-oxide surface layer that is invisible but strong enough to prevent further oxygen from "staining" (rusting) the surface. Higher levels of chromium and the addition of other alloying elements such as nickel and molybdenum enhance this surface layer and improve the corrosion resistance of the stainless material.

Q5: Can stainless steel rust?

A5: Stainless does not "rust" as you think of regular steel rusting with a red oxide on the surface that flakes off. If you see red rust it is probably due to some iron particles that have contaminated the surface of the stainless steel and it is these iron particles that are rusting. Look at the source of the rusting and see if you can remove it from the surface.

Images:

- Q:What are the common heat treatment processes for steel wire rod?

- Steel wire rods undergo various heat treatment processes to enhance their properties and characteristics. These processes, including annealing, quenching, tempering, and normalizing, serve specific purposes. 1. Annealing involves heating the steel wire rod to a specific temperature and maintaining it for a certain duration, followed by controlled cooling. This process enhances the material's ductility and machinability by reducing its hardness and brittleness. 2. Quenching is a rapid cooling process in which the heated wire rod is immersed in a quenching medium like oil or water. This rapid cooling increases the wire rod's strength and hardness but also makes it more brittle. 3. Tempering is done after quenching to reduce brittleness and relieve internal stresses. The quenched wire rod is heated to a specific temperature and held there for a certain period, followed by controlled cooling. Tempering improves the wire rod's toughness and ductility while maintaining a desirable level of strength. 4. Normalizing is a heat treatment process similar to annealing, but with a different cooling method. The wire rod is heated above its transformation range and allowed to cool in still air. Normalizing refines the material's grain structure, improving its mechanical properties and reducing internal stresses. These heat treatment processes can be combined and modified to achieve specific desired properties for steel wire rods. The choice of process depends on factors such as the desired mechanical properties, intended application, and the type of steel being treated.

- Q:What are the standard impact strength requirements for steel wire rod?

- The impact strength requirements of steel wire rod can differ based on the specific application and industry standards. However, in general, steel wire rod needs to have good impact strength properties to ensure durability and resistance against breakage in dynamic loading situations. Various international standards organizations like ASTM International, ISO, and national standards bodies establish the impact strength requirements. These standards offer guidelines for determining the impact strength of steel wire rod through standardized testing methods. To fulfill the standard impact strength requirements, steel wire rod is often subjected to impact tests such as Charpy or Izod tests. These tests involve striking a notched sample of the wire rod with a pendulum hammer and measuring the energy absorbed during fracture. The results provide an indication of the material's ability to endure sudden shock or impact. The specific impact strength requirements for steel wire rod can differ based on factors such as the intended application, industry regulations, and customer specifications. For instance, wire rod used in construction may have different impact strength requirements compared to wire rod used in automotive manufacturing. In summary, the impact strength requirements for steel wire rod are determined by international and national standards organizations and can vary depending on the application. Complying with these requirements ensures that the wire rod possesses the necessary strength and resilience to withstand impact and dynamic loading conditions.

- Q:What are the common applications of low alloy steel wire rod?

- Low alloy steel wire rod has various common applications due to its specific properties and characteristics. Some of the most common applications of low alloy steel wire rod include: 1. Construction industry: Low alloy steel wire rod is widely used in the construction industry for reinforcing concrete structures. It is commonly used to manufacture welded wire mesh, which is used to reinforce concrete slabs, walls, and foundations. The high strength and durability of low alloy steel wire rod make it an ideal choice for withstanding heavy loads and preventing structural failure. 2. Automotive industry: Low alloy steel wire rod is extensively used in the automotive industry for manufacturing various components. It is commonly used to produce springs, suspension systems, and other high-stress components that require excellent strength and fatigue resistance. The low alloy steel wire rod's ability to withstand heavy loads and constant stress makes it well-suited for automotive applications. 3. Manufacturing industry: Low alloy steel wire rod is also used in various manufacturing processes. It is commonly employed in the production of fasteners, such as screws, bolts, and nuts, due to its high tensile strength. Additionally, low alloy steel wire rod is used for manufacturing wire ropes, cables, and other high-strength wire products that require durability and resistance to corrosion. 4. Engineering industry: Low alloy steel wire rod finds applications in the engineering industry for fabricating structural components, machinery parts, and equipment. It is often used for manufacturing gears, shafts, and bearings due to its excellent wear resistance and ability to withstand heavy loads. The low alloy steel wire rod's properties make it a reliable choice for critical engineering applications. 5. Electrical industry: Low alloy steel wire rod is used in the electrical industry for manufacturing various electrical conductors and components. It is commonly used to produce overhead power lines, electrical cables, and wires due to its high electrical conductivity and mechanical strength. The low alloy steel wire rod's ability to carry electricity efficiently and its resistance to mechanical stress make it suitable for electrical applications. In summary, low alloy steel wire rod has a wide range of applications in the construction, automotive, manufacturing, engineering, and electrical industries. Its high strength, durability, wear resistance, and electrical conductivity make it a versatile material for various applications that require reliability and performance.

- Q:What are the common production processes for mendelevium-coated steel wire rod?

- The common production processes for mendelevium-coated steel wire rod typically involve several steps. First, the steel wire rod is cleaned and prepared to ensure a smooth surface. It is then coated with a layer of mendelevium using techniques such as physical vapor deposition or electroplating. The coated wire rod is then cured or heat treated to enhance the adhesion of the mendelevium layer. Finally, the wire rod is cut and packaged for distribution or further processing.

- Q:How is steel wire rod used in the manufacturing of automotive seat frames?

- Steel wire rod is commonly used in the manufacturing of automotive seat frames as it provides strength and durability. It is typically shaped and bent into various configurations to form the frame structure. The steel wire rod's high tensile strength ensures the seat frame can withstand the weight and movement of occupants, while its flexibility allows for easy shaping and customization. Additionally, the use of steel wire rod helps to enhance the overall safety and stability of automotive seats, ensuring a comfortable and secure seating experience for passengers.

- Q:How is steel wire rod used in the manufacturing of wire forms for electrical connectors?

- Steel wire rod is an essential component in the manufacturing of wire forms for electrical connectors. The wire rod serves as the raw material that is transformed into various wire forms, such as pins, sockets, and terminals, which are crucial components of electrical connectors. The manufacturing process begins with the selection of high-quality steel wire rod, which is typically made of carbon steel or stainless steel. The wire rod is carefully chosen based on its specific properties, such as strength, flexibility, and conductivity, to ensure that the resulting wire forms meet the required standards and specifications. Once the appropriate wire rod is selected, it undergoes a series of manufacturing operations. The first step is to draw the wire rod through a series of dies and reduce its diameter to the desired size. This process is known as wire drawing and is performed to achieve the required thickness and smoothness of the wire form. After wire drawing, the wire rod is then straightened and cut into specific lengths. These lengths are determined based on the design and dimensions of the wire forms required for the electrical connectors. The straightening and cutting process ensures that the wire forms are uniform and consistent in size. The next step involves bending and shaping the wire rod into the desired form. This is typically achieved through the use of specialized machines and tools that can bend the wire rod into various configurations, such as loops, hooks, or specific geometrical shapes. These wire forms are designed to fit and connect with other components of the electrical connectors. Once the wire forms are shaped, they undergo additional processes such as heat treatment or plating to enhance their mechanical properties or improve their resistance to corrosion. These treatments ensure that the wire forms can withstand the demanding conditions and provide reliable connectivity in electrical applications. In conclusion, steel wire rod plays a critical role in the manufacturing of wire forms for electrical connectors. Through a series of manufacturing processes, the wire rod is transformed into various wire forms that are essential components of electrical connectors. These wire forms provide reliable connectivity and ensure the proper functioning of electrical systems.

- Q:What are the common industry qualifications for steel wire rod suppliers?

- The common industry qualifications for steel wire rod suppliers typically include certifications such as ISO 9001, ISO 14001, and OHSAS 18001, which ensure quality management systems, environmental responsibility, and occupational health and safety standards are in place. Additionally, suppliers may be required to adhere to specific industry standards like ASTM International or EN standards to ensure the product's compliance and reliability.

- Q:What are the environmental impacts of producing steel wire rod?

- The production of steel wire rod can have various environmental impacts, both during the extraction of raw materials and the manufacturing process. Here are some of the key environmental impacts associated with producing steel wire rod: 1. Resource extraction: Steel wire rod is primarily made from iron ore, which requires extensive mining activities. These mining operations can lead to deforestation, habitat destruction, and soil erosion. Furthermore, the extraction and transportation of iron ore contributes to greenhouse gas emissions and air pollution. 2. Energy consumption: The production of steel wire rod involves several energy-intensive processes, such as smelting, refining, and shaping. These processes typically rely on fossil fuels, such as coal and natural gas, which release large amounts of carbon dioxide into the atmosphere. High energy consumption not only contributes to climate change but also depletes non-renewable resources. 3. Air and water pollution: The manufacturing process for steel wire rod can release various pollutants into the air and water. During smelting, emissions of sulfur dioxide, nitrogen oxides, and particulate matter can contribute to air pollution and acid rain. Water pollution can occur through the discharge of wastewater containing heavy metals, oil, and chemicals used in the production process, potentially contaminating nearby water bodies. 4. Waste generation: Steel wire rod production generates significant amounts of waste materials, including slag, dust, and sludge. These waste products often contain harmful substances, such as heavy metals and toxic chemicals, which can pollute the environment if not properly managed. Waste disposal can also contribute to land degradation and the depletion of natural resources. 5. Carbon emissions: Steel production, including the production of wire rod, is a major contributor to global carbon emissions. The high temperatures required to convert iron ore into steel result in the release of large amounts of carbon dioxide. Additionally, the use of fossil fuels in the manufacturing process further adds to the carbon footprint of steel wire rod production. To mitigate these environmental impacts, the steel industry has been adopting various measures such as implementing cleaner technologies, improving energy efficiency, and reducing reliance on fossil fuels. Additionally, recycling steel scrap can significantly reduce the environmental burden associated with steel wire rod production.

- Q:What are the main factors affecting the product competitiveness of steel wire rod?

- The main factors affecting the product competitiveness of steel wire rod include the quality and consistency of the product, pricing competitiveness, delivery reliability, customer service, technical support, and the ability to meet specific customer requirements. Additionally, factors such as the reputation and brand image of the manufacturer, market demand and trends, competition from other suppliers, and the cost and availability of raw materials also play a significant role in determining the product's competitiveness.

- Q:Can steel wire rod be used in the production of springs?

- Steel wire rod is a versatile material that finds wide application in the production of springs. This material is favored for its exceptional strength, durability, and flexibility. It can be effortlessly molded and shaped into an assortment of spring designs, including compression springs, extension springs, and torsion springs. To achieve the desired properties and specifications for a specific spring application, the steel wire rod typically undergoes a series of manufacturing steps such as drawing, coiling, heat treatment, and surface finishing. In conclusion, steel wire rod is an optimal choice for spring production owing to its mechanical properties and suitability for diverse industrial and commercial uses.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Carbon Steel Hot Rolled Wire Rod SAE1008 SAE1006 SAE1018

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 40000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords