Carbon Steel Flat with Q195-Q235 for Construction

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification of Carbon Steel Flat with Q195-Q235 for Construction:

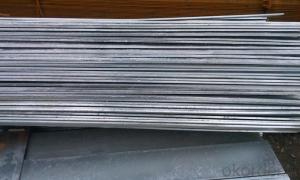

Commodity: Hot Rolled Steel Flat Bar

Standard: GB;JIS

Material: Q195-Q235

Brand name: FLATSPACE

Origin place: China

Thickness: 3mm-30mm

Width:20mm-200mm

Length: Max 12m

Certification: SGS/BV

Usage/Applications of Carbon Steel Flat with Q195-Q235 for Construction:

Widely used for construction, Machinery manufacturing, Iron tower steel structure, Shipbuilding; Steel grating, Staircase, Bridge, Viaduct, Railway spare parts, Boilers making etc.

Production Flow of Carbon Steel Flat with Q195-Q235 for Construction:

The steel flat bar is made through three processes:

1.Feeding the material: Feeding the row material (the steel plate) to Slitting Line.

2.Slitting:The steel plate would be slitted into expected width by lengthways cutter.

3. Leveled and cutting: The plat bar would be ground into level by the grinder and then cut into required length.

Packaging & Delivery of Carbon Steel Flat with Q195-Q235 for Construction:

1.Packaging Details: The Steel Flat Bars are packed in bundles and loaded in 20 feet/40 feet container, or shipped by bulk cargo ,also we can do as customer's requirements.

2.Delivery Details:30~45 days upon the receipt of buyer payment by T.T. or L/C.

3. Marks:

Color marking: There will be color marking on both end of the bundle for the cargo delivered by bulk vessel. That makes it easily to distinguish at the destination port.

Tag mark: there will be tag mark tied up on the bundles. The information usually including supplier logo and name, product name, made in China, shipping marks and other information request by the customer.

If loading by container the marking is not needed, but we will prepare it as customer requests.

FAQ:

Q1: Why buy Materials & Equipment from OKorder.com?

A1: All products offered byOKorder.com are carefully selected from China's most reliable manufacturing enterprises. Through its ISO certifications, OKorder.com adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q3: How soon can we receive the product after purchase?

A3: Within three days of placing an order, we will begin production. The specific shipping date is dependent upon international and government factors, but is typically 7 to 10 workdays.

Images:

- Q:Are steel flat bars suitable for outdoor applications?

- Steel flat bars are well-suited for outdoor use. The durability and strength of steel make it an excellent choice for this purpose. In fact, steel flat bars can endure harsh weather conditions, including rain, snow, and extreme temperatures, without compromising their structural integrity. They are also resistant to corrosion and can withstand exposure to moisture and UV rays. This makes them perfect for outdoor projects. Moreover, steel flat bars are highly versatile and can be easily welded, bent, or shaped to meet specific requirements. This makes them suitable for a wide range of outdoor applications, such as fences, gates, handrails, and outdoor furniture. All in all, steel flat bars are a dependable and long-lasting option for outdoor use.

- Q:Can steel flat bars be used for making heat exchangers or cooling systems?

- Yes, steel flat bars can be used for making heat exchangers or cooling systems. Steel is commonly used in the construction of heat exchangers due to its high thermal conductivity, strength, and corrosion resistance. The flat bars can be formed and welded together to create the required shapes and structures for efficient heat transfer and cooling processes.

- Q:Are steel flat bars suitable for making electrical enclosures or cabinets?

- Yes, steel flat bars are suitable for making electrical enclosures or cabinets. Steel flat bars offer excellent strength and durability, making them ideal for providing adequate protection and support for electrical components. They can also be easily welded or bolted together, allowing for the construction of custom designs and configurations. Additionally, steel flat bars can withstand various environmental conditions, ensuring the longevity and reliability of the electrical enclosures or cabinets.

- Q:How do steel flat bars compare to plastic flat bars?

- Steel flat bars are generally stronger and more durable than plastic flat bars. Steel is a highly resilient material that can withstand heavy loads, making it suitable for applications where strength and stability are essential. On the other hand, plastic flat bars are lighter and more flexible, but they lack the same level of strength and durability as steel. The choice between steel and plastic flat bars ultimately depends on the specific requirements and intended use of the bars.

- Q:Are steel flat bars suitable for making brackets or supports?

- Yes, steel flat bars are commonly used for making brackets or supports due to their strength, durability, and versatility. They provide excellent structural support and can withstand heavy loads, making them suitable for various applications in construction, engineering, and manufacturing.

- Q:What is the difference between a steel flat bar and a steel round bar?

- The main difference between a steel flat bar and a steel round bar lies in their shape and functionality. A steel flat bar has a rectangular cross-section and a flat surface, making it suitable for applications that require a wide, even load-bearing surface. On the other hand, a steel round bar has a circular cross-section and is often used in applications where strength, durability, and resistance to bending or twisting forces are required. Additionally, the shape of the round bar allows for easier machining and shaping compared to the flat bar. Ultimately, the choice between a steel flat bar and a steel round bar depends on the specific requirements and intended use of the material.

- Q:How do steel flat bars contribute to the overall sustainability of structures?

- There are several ways in which steel flat bars contribute to the overall sustainability of structures. Firstly, the use of steel flat bars ensures that structures have a longer lifespan compared to those made with other materials, as steel is highly durable and long-lasting. This reduces the need for frequent repairs or replacements, resulting in less waste and a lower overall environmental impact. Secondly, steel is a highly recyclable material, and flat bars can be easily melted down and reshaped into new products without losing their inherent properties. This reduces the demand for new steel production and the extraction of raw materials, leading to a significant decrease in energy consumption and greenhouse gas emissions. Furthermore, steel flat bars have a high strength-to-weight ratio, meaning that less material is needed to achieve the same structural integrity compared to other materials. This results in lighter structures, which require less energy for transportation and installation. Additionally, the reduced weight allows for more efficient designs, enabling the use of smaller foundations and fewer materials overall. Moreover, steel flat bars offer versatility in design and construction. They can be easily fabricated into various shapes and sizes, allowing architects and engineers to create innovative and efficient structures. The flexibility of steel flat bars also allows for greater adaptability and reusability, as structures can be modified or repurposed instead of being demolished and rebuilt. Lastly, steel is highly resistant to natural disasters such as earthquakes, hurricanes, and fires. Structures built with steel flat bars can withstand these events better, reducing the potential for severe damage and the need for complete reconstruction. In conclusion, the incorporation of steel flat bars into construction projects contributes to the overall sustainability of structures by providing durability, recyclability, lightweight design, versatility, and resilience to natural disasters. This not only minimizes waste and reduces energy consumption, but also lowers greenhouse gas emissions and creates long-lasting, environmentally friendly structures.

- Q:What is the maximum load capacity of a steel flat bar?

- The maximum load capacity of a steel flat bar depends on various factors such as the dimensions of the bar, the quality and grade of the steel, and the method of load application. Generally, steel flat bars are designed to withstand significant loads due to their high tensile strength and durability. However, it is important to consult the manufacturer's specifications or perform structural calculations to determine the exact maximum load capacity for a specific steel flat bar.

- Q:How do you determine the dimensions of a steel flat bar?

- In order to ascertain the dimensions of a steel flat bar, it is necessary to measure its width, thickness, and length. To begin, employ a tape measure or ruler to gauge the width of the flat bar. Place the measuring instrument perpendicular to the bar's longest edges, and record the measurement in either inches or millimeters. Proceed by determining the thickness of the flat bar. This can be accomplished by situating the tape measure or ruler on one of the bar's narrow edges and measuring the distance between the two flat surfaces. Once again, document the measurement in inches or millimeters. Lastly, measure the length of the steel flat bar. This can be achieved by situating the tape measure or ruler parallel to the bar's longest edges and measuring from one end to the other. Ensure that the measurement is noted in either inches or millimeters. By accurately measuring the width, thickness, and length of the steel flat bar, its dimensions can be determined. These measurements are crucial for a variety of applications, such as construction, manufacturing, or fabrication, where precise dimensions are imperative for proper fitting and utilization.

- Q:How is a steel flat bar made?

- The typical method for manufacturing a steel flat bar involves a process known as hot rolling. To begin, a large steel billet or slab is heated to a high temperature, usually around 1200 to 1300 degrees Celsius. Once heated, the billet is then passed through rolling mills where it is gradually flattened and shaped into a long and thin strip called a flat bar. Inside each rolling mill, the steel billet goes through a pair of rotating rolls that apply pressure and reduce its thickness. The billet is rolled multiple times, with the gap between the rolls decreasing after each pass. This continuous rolling process helps to refine the grain structure of the steel, enhancing its strength and durability. Once the desired thickness is achieved, the flat bar may undergo additional processes such as cooling, straightening, and cutting. Cooling is typically done by using air or water to rapidly cool the steel, solidifying its desired properties. Straightening ensures that any bends or twists that occurred during the rolling process are removed, resulting in a uniform flat shape. After the flat bar is cooled and straightened, it is cut into individual lengths using machines designed for shearing or sawing. These lengths can then be further processed or used as is for a variety of applications. In summary, producing a steel flat bar involves heating a steel billet, hot rolling it through rolling mills to achieve the desired thickness, cooling, straightening, and finally cutting it into individual lengths. This process yields a versatile and widely used product that is utilized in industries such as construction, manufacturing, and automotive.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Carbon Steel Flat with Q195-Q235 for Construction

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords