Carbon Raiser Caclined Anthracite Coal CA

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

Place of Origin: Ningxia, China (Mainland)

Application: steel making

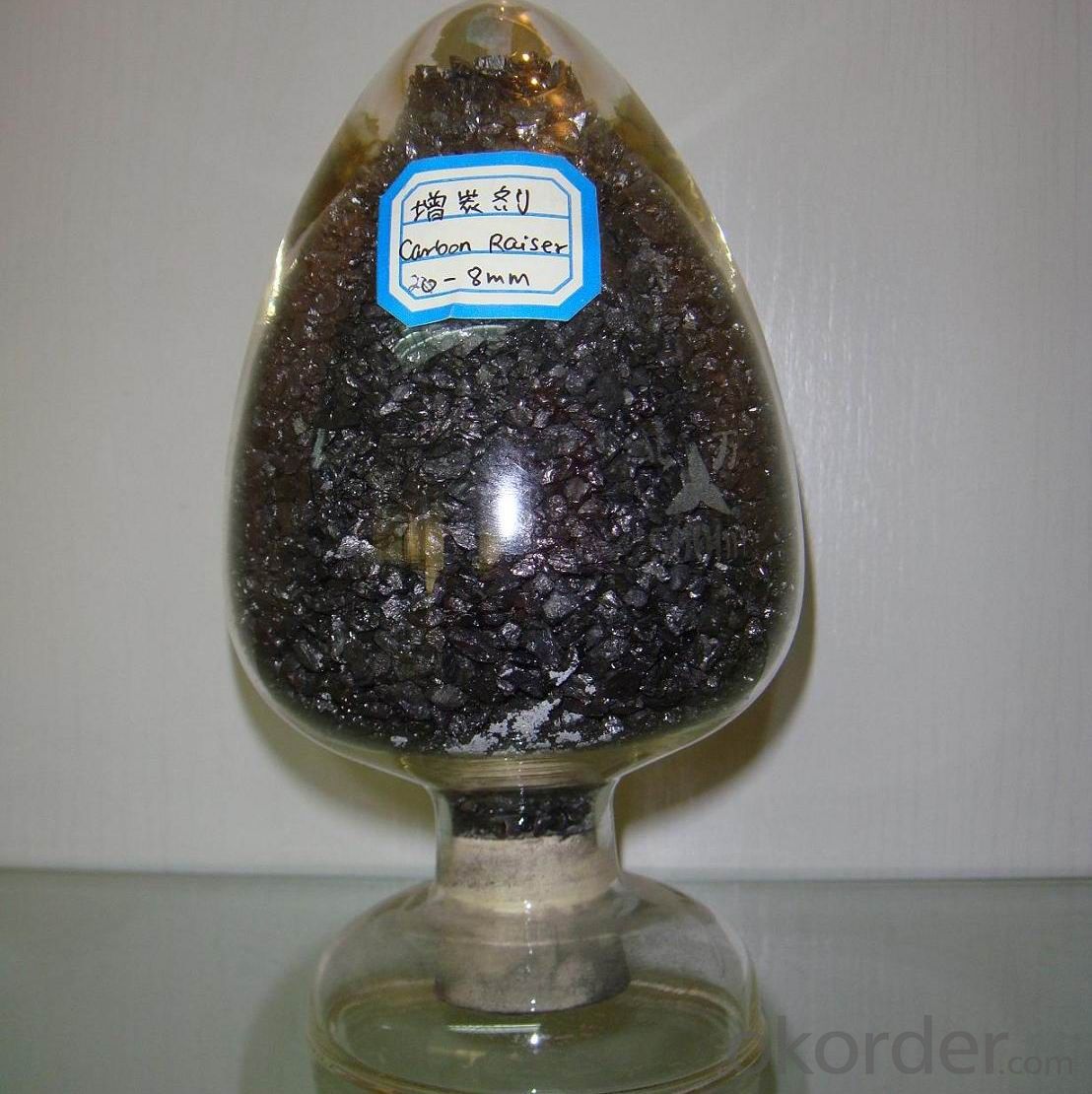

Shape: granule

Dimensions: FC90-95%

Product Type: Carbon Additive

C Content (%): 90-95% MIN

Working Temperature: -

S Content (%): 0.5%MAX

N Content (%): -

H Content (%): 0.6%MAX

Ash Content (%): 8.5%MAX

Volatile: 2%MAX

ADVANTAGE: low ash & sulfur

COLOR: Black

RAW MATERIAL: TaiXi anthracite

Packaging & Delivery

| Packaging Details: | In 1MT plastic woven bag. |

|---|---|

| Delivery Detail: | 30-40DAYS |

Specifications

Carbon Raiser Caclined Anthracite Coal CA

Carbon Additve low Ash,S,P

FC>95% ASH<4% S<0.3%

It is made from TaiXi anthracite.

instead of pertrol coke reduce the cost

Structure

Carbon Raiser Caclined Anthracite Coal CA

Shape: granule

Dimensions: FC90-95%

Product Type: Carbon Additive

C Content (%): 90-95% MIN

Working Temperature: -

S Content (%): 0.5%MAX

N Content (%): -

H Content (%): 0.6%MAX

Ash Content (%): 8.5%MAX

Volatile: 2%MAX

ADVANTAGE: low ash & sulfur

COLOR: Black

RAW MATERIAL: TaiXi anthracite

Feature

Carbon Raiser Caclined Anthracite Coal CA

Specifications (%): | ||||||

Grade | F.C | Ash | V.M | Moisture | S | Size |

CR-95 | ≥95 | <4 | <1 | <1 | <0.3 | 0-30mm |

CR-94 | ≥94 | <4 | <1 | <1 | <0.3 | |

CR-93 | ≥93 | <6 | <1 | <1 | <0.4 | |

CR-92 | ≥92 | <7 | <1 | <1 | <0.4 | |

CR-91 | ≥91 | <8 | <1 | <1 | <0.4 | |

CR-90 | ≥90 | <8.5 | <1.5 | <2 | <0.4 | |

Image

Carbon Raiser Caclined Anthracite Coal CA

FAQ:

Carbon Raiser Caclined Anthracite Coal CA

Why we adopt carbon additive?

Carbon Additives used as additive in steel making process. It made from well-selected Tai Xi anthracite which is low in content of ash, sulphur, phosphorus, high heat productivity, high chemically activation.

Mainly industry property of it is: instead of traditional pertroleum coal of Carbon Additives, reduce the cost of steelmaking.

Advantage:

Carbon Raiser Caclined Anthracite Coal CA

1.High quality and competitive price.

2.Timely delivery.

3.If any item you like. Please contact us.

Your sincere inquiries are typically answered within 24 hours.

- Q:How does carbon contribute to the strength of concrete?

- There are several ways in which carbon can contribute to the strength of concrete. One primary method involves the utilization of carbon nanotubes (CNTs) or carbon fibers. These substances are added to the concrete mixture to act as reinforcement and enhance its mechanical properties. Incorporating CNTs or carbon fibers into the concrete results in the formation of a network consisting of small, sturdy, and lightweight particles. This network serves to enhance the overall strength and durability of the concrete, making it more resistant to cracking, flexing, and other types of structural damage. Furthermore, the carbon particles also improve the bonding between the cement paste and the aggregates in the concrete. This improved bonding increases the strength at the interface, resulting in a more cohesive and robust concrete matrix. Moreover, carbon can also contribute to the strength of concrete by acting as a pozzolan. Pozzolans are materials that undergo a chemical reaction with calcium hydroxide, a byproduct of cement hydration, to form additional cementitious compounds. These compounds fill in the gaps between cement particles, leading to a denser and stronger concrete structure. Carbon black, which is a finely divided form of carbon, is commonly used as a pozzolan in concrete mixtures. Overall, the incorporation of carbon in concrete, whether through carbon nanotubes, carbon fibers, or as a pozzolan, can significantly enhance its strength and performance. By reinforcing the concrete matrix, improving bonding, and filling in gaps, carbon helps create a more durable and robust material suitable for various construction applications.

- Q:A carbon Roast Lamb Leg stores need to how much money

- Do about 50 thousand! Do not have their own skills, you have to learn, have time to look at the Weifang green, Mongolia edge, taste and scale are pretty good!

- Q:What are the advantages of carbon nanotube transistors?

- Traditional silicon-based transistors are outshined by carbon nanotube transistors for several reasons. Firstly, carbon nanotubes boast exceptional electrical properties with their high electron mobility, enabling swift and effortless electron movement. This results in faster switching speeds and higher operating frequencies, making them a perfect fit for high-performance applications like computers and communication devices. Secondly, carbon nanotubes possess an incredibly small size, measuring a mere few nanometers in diameter. This miniature scale allows for the creation of highly compact and densely packed electronic circuits, leading to elevated integration levels and enhanced device functionality. In comparison, silicon transistors pale in comparison as they have feature sizes several orders of magnitude larger. Moreover, carbon nanotubes exhibit superior heat resistance and thermal conductivity compared to silicon. This exceptional trait enables them to withstand higher temperatures without degradation, resulting in more efficient operation and a reduced need for elaborate cooling systems. Additionally, their ability to endure harsh environments makes them highly suitable for aerospace, automotive, and defense applications. Furthermore, carbon nanotubes are remarkably robust and flexible. They can be bent and stretched without breaking, making them ideal for use in flexible electronics and wearable devices. Their mechanical strength ensures long-term stability and reliability, ultimately leading to improved device performance and longevity. Lastly, carbon nanotube transistors can be fabricated using existing manufacturing processes, making them compatible with current semiconductor technologies. This compatibility allows for their seamless integration into existing electronic systems without the need for significant modifications, thereby reducing both cost and implementation time. All in all, the myriad advantages of carbon nanotube transistors, including their exceptional electrical performance, small size, thermal stability, mechanical strength, and compatibility with existing manufacturing processes, position them as a promising alternative to traditional silicon transistors for future electronic applications.

- Q:How does carbon impact the availability of natural resources?

- The availability of natural resources is significantly impacted by carbon dioxide (CO2), which is a form of carbon. When fossil fuels like coal, oil, and natural gas are burned, they release large amounts of CO2 into the atmosphere. This excessive release of CO2 is responsible for the greenhouse effect, which leads to global warming and climate change. Climate change has a major effect on natural habitats and ecosystems. It directly affects the availability of various natural resources by causing rising temperatures and changing weather patterns. For example, higher temperatures can result in the melting of glaciers and ice caps, which affects the availability of freshwater resources for human consumption and agriculture. Furthermore, carbon emissions contribute to the acidification of oceans, which harms marine life. Coral reefs, for instance, are highly sensitive to changes in water chemistry. Increased acidity due to elevated CO2 levels can bleach and eventually kill coral reefs. This not only impacts ocean biodiversity but also affects the availability of fish and other seafood resources that many communities depend on. Moreover, climate change caused by carbon emissions disrupts ecosystems and leads to the extinction or displacement of numerous plant and animal species. This has cascading effects on the availability of resources like timber, medicinal plants, and other valuable natural products sourced from forests and other ecosystems. In addition, carbon emissions contribute to air pollution, which has adverse effects on human health. High concentrations of airborne pollutants, including particulate matter, can cause respiratory diseases and other health issues. This strains healthcare systems and reduces the productivity and overall well-being of communities. To mitigate the negative impacts of carbon emissions on the availability of natural resources, it is crucial to transition to cleaner and more sustainable energy sources, such as renewable energy. This shift would reduce reliance on fossil fuels and subsequently decrease carbon emissions, thus helping preserve and protect our natural resources for future generations.

- Q:How is carbon used in the production of solar cells?

- Carbon is not directly used in the production of solar cells. Solar cells are typically made of semiconductor materials like silicon or cadmium telluride. However, carbon-based materials can play a crucial role in enhancing the performance and efficiency of solar cells. One way carbon is used is in the form of carbon nanotubes, which can be used as a transparent electrode in solar cells. Carbon nanotubes have excellent electrical conductivity and optical transparency, making them an ideal candidate for replacing traditional transparent conductive materials like indium tin oxide. Additionally, carbon-based materials can be used as a coating or encapsulation layer, providing protection to the solar cells from moisture, corrosion, and mechanical stress. Carbon-based materials also have the potential to be used in the development of next-generation solar cell technologies, such as organic solar cells or perovskite solar cells, which utilize carbon-based compounds in their active layers. Overall, while carbon may not be directly used in the production of solar cells, it plays a crucial role in improving their performance and enabling the development of more advanced solar cell technologies.

- Q:What are the consequences of increased carbon emissions on social inequality?

- Social inequality is profoundly affected by the increase in carbon emissions. The main consequence is the worsening of existing inequalities, especially in disadvantaged communities. Firstly, marginalized communities, including low-income neighborhoods and developing countries, are disproportionately affected by the effects of climate change caused by carbon emissions. These communities often lack the necessary resources and infrastructure to withstand extreme weather events like hurricanes or flooding, which makes them more vulnerable and leads to loss of livelihoods. Secondly, the economic impact of carbon emissions, such as higher energy costs and reduced agricultural productivity, widens the gap between the rich and the poor. Wealthy individuals can adapt to these changes, while those with limited financial resources struggle to cope, resulting in increased poverty and socio-economic disparities. Furthermore, carbon emissions contribute to health disparities. Low-income neighborhoods, where industrial plants and highways are often located, are disproportionately affected by polluted air caused by carbon emissions. This leads to higher rates of respiratory diseases and other health issues in marginalized communities, exacerbating existing health inequalities. Moreover, the consequences of climate change, driven by carbon emissions, can force communities to relocate, resulting in social disruption and increased competition for resources. This further marginalizes vulnerable populations and creates conflicts over land and resource access. Lastly, the consequences of carbon emissions on social inequality are not limited to specific regions but have global implications. Developing countries, which contribute less to carbon emissions but bear a disproportionate burden of the impacts, face significant challenges in addressing climate change due to limited resources and technological capabilities. This perpetuates global inequalities. In conclusion, the increase in carbon emissions has severe consequences for social inequality. It amplifies existing disparities, particularly affecting marginalized communities, through the disproportionate impacts of climate change, economic hardships, health disparities, forced displacement, and global inequalities. Addressing carbon emissions and climate change is essential not only for environmental sustainability but also for promoting social justice and reducing social inequality.

- Q:How is carbon used in the production of activated carbon filters?

- Activated carbon filters are widely used in various industries and applications, such as water and air purification, gas masks, and even in the production of certain chemicals. In the production of activated carbon filters, carbon plays a crucial role in their effectiveness. Activated carbon, also known as activated charcoal, is a highly porous form of carbon that has a large surface area. This porous structure is achieved through a process called activation, which involves heating carbonaceous materials, such as wood, coal, or coconut shells, at high temperatures in the presence of steam or certain chemicals. The activation process creates tiny pores and increases the surface area of the carbon, allowing it to effectively trap and remove impurities from gases or liquids. These impurities, including organic compounds, volatile organic compounds (VOCs), and certain heavy metals, are attracted to the surface of the activated carbon due to its high adsorption capacity. In the production of activated carbon filters, the activated carbon is typically formed into a granular or powdered form and then packed into a filter medium, such as a cartridge or a mesh. The filter medium acts as a support structure for the activated carbon, allowing the air or water to flow through while capturing and adsorbing the impurities. The activated carbon filters can effectively remove a wide range of contaminants, including chlorine, volatile organic compounds (VOCs), odors, and certain heavy metals. This makes them highly efficient in improving the quality of water and air by reducing pollutants and enhancing odor control. Moreover, the versatility of activated carbon allows for customization depending on the specific application. For example, activated carbon can be impregnated with certain chemicals to enhance its adsorption capacity for specific contaminants, or it can be specially treated to target certain pollutants, such as mercury or arsenic. In summary, carbon is used in the production of activated carbon filters due to its highly porous structure and excellent adsorption properties. These filters are crucial in various industries and applications, effectively removing impurities from water and air, improving their quality, and enhancing overall environmental and human health.

- Q:What is carbon black pigment?

- Carbon black pigment is a finely divided form of carbon that is primarily used as a coloring agent in various applications. It is produced by the incomplete combustion or thermal decomposition of hydrocarbons, such as coal tar, petroleum, or natural gas. The resulting carbon black particles are extremely small and have a high surface area, which gives them unique properties. Carbon black pigment is known for its intense black color, high tinting strength, and excellent UV stability. It is widely used in the production of inks, paints, coatings, plastics, rubber, and various other materials. The pigment particles disperse well in these mediums, providing a deep and uniform black coloration. In addition to its coloring capabilities, carbon black pigment also offers several other desirable properties. It enhances the durability, weather resistance, and electrical conductivity of materials. It can also improve the UV resistance and absorption properties of coatings and plastics, making them more resistant to fading and degradation caused by sunlight exposure. Moreover, carbon black pigment is chemically inert and does not react with other substances. This makes it suitable for use in a wide range of applications without causing any undesired chemical reactions. It is also non-toxic and has a low environmental impact, making it a preferred choice for many industries. Overall, carbon black pigment is a versatile and widely used additive that provides deep black coloration, durability, and enhanced performance to a variety of materials. Its unique properties make it an essential component in numerous industries, contributing to the production of high-quality products.

- Q:Is the power consumption of carbon fiber heating very high?

- The advantages and disadvantages of carbon fiber heating carbon fiber heating, comfortable and natural advantages of 1: the ground heating source, on the human body at the end of the foot has a good heating, health effects, and health effects of carbon fiber far infrared heating to improve the microcirculation of the human body, make the body feel very comfortable. 2, heating rapidly: carbon fiber thermal conductivity is good, so carbon fiber heating ground heating faster. 3, installation and maintenance cost is low, long service life: carbon fiber heating laying low cost, 100 square meters of house, generally laying price, but 10000 yuan, usually without maintenance, and product life and construction life is quite.

- Q:Is badminton all good as carbon or aluminum carbon? Does carbon fiber on the Internet mean total carbon?

- Products using what material is an important factor to determine its price under the table, can let you understand the properties of several materials and approximate cost: the hardness of the material strength shock probably cost RMB $/KG high strength carbon fiber carbon fiber (HighModulusGraphite) 874157 (Graphite/ Carbon) 58445 (Aluminum) 24115 Aluminum Alloy wood (wood) 11104 must pay attention to in the choice of the racket, don't put the whole aluminum frame carbon rod racket mistaken for full carbon badminton racket. General note the label on the racket, should be able to distinguish, if not sure, I have three methods that can be used, one hand touch frame Aluminum Alloy good thermal conductivity due to the frame model is cool and the carbon frame is warm. But look at the groove on the racket frame, the aluminum frame is concave inside the shallow arc, and the carbon frame is an inner concave trapezoid. Three is to feel the weight, the aluminum frame's racket head is obviously biased. As the transition from aluminum frame to full carbon product, I feel that the price is high and the performance is low, it is not a good choice.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Carbon Raiser Caclined Anthracite Coal CA

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords