Carbon Additve Low Ash sulphur for Steelmaking

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

Place of Origin: Ningxia, China (Mainland)

Application: steel making

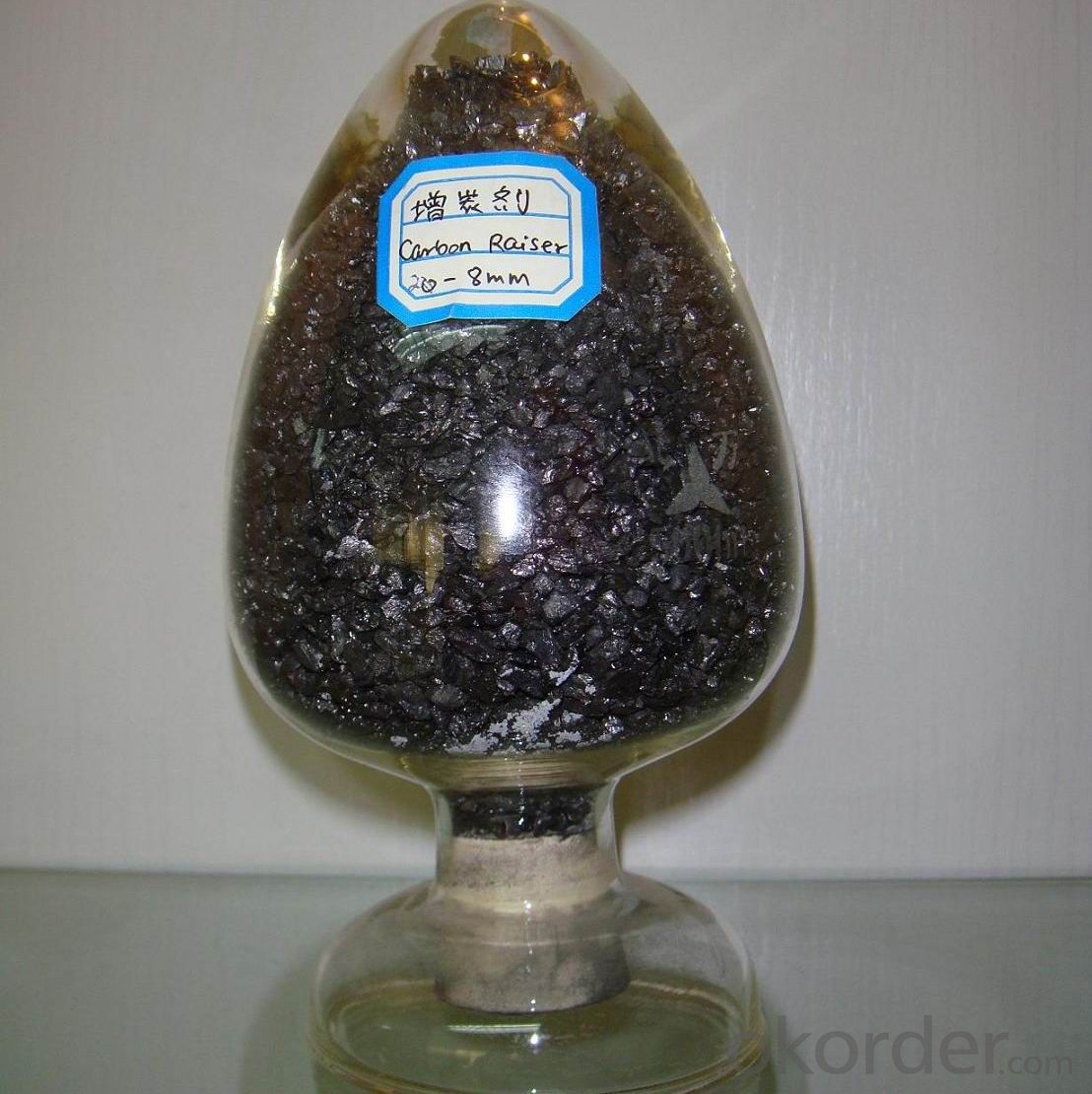

Shape: granule

Dimensions: FC90-95%

Product Type: Carbon Additive

C Content (%): 90-95% MIN

Working Temperature: -

S Content (%): 0.5%MAX

N Content (%): -

H Content (%): 0.6%MAX

Ash Content (%): 8.5%MAX

Volatile: 2%MAX

ADVANTAGE: low ash & sulfur

COLOR: Black

RAW MATERIAL: TaiXi anthracite

Packaging & Delivery

| Packaging Details: | In 1MT plastic woven bag. |

|---|---|

| Delivery Detail: | 30-40DAYS |

Specifications

Carbon Additve Low Ash Sulphur for Steelmaking

Carbon Additve low Ash,S,P

FC>95% ASH<4% S<0.3%

It is made from TaiXi anthracite.

instead of pertrol coke reduce the cost

Structure

Carbon Additve Low Ash Sulphur for Steelmaking

Shape: granule

Dimensions: FC90-95%

Product Type: Carbon Additive

C Content (%): 90-95% MIN

Working Temperature: -

S Content (%): 0.5%MAX

N Content (%): -

H Content (%): 0.6%MAX

Ash Content (%): 8.5%MAX

Volatile: 2%MAX

ADVANTAGE: low ash & sulfur

COLOR: Black

RAW MATERIAL: TaiXi anthracite

Feature

Carbon Additve Low Ash Sulphur for Steelmaking

Specifications (%): | ||||||

Grade | F.C | Ash | V.M | Moisture | S | Size |

CR-95 | ≥95 | <4 | <1 | <1 | <0.3 | 0-30mm |

CR-94 | ≥94 | <4 | <1 | <1 | <0.3 | |

CR-93 | ≥93 | <6 | <1 | <1 | <0.4 | |

CR-92 | ≥92 | <7 | <1 | <1 | <0.4 | |

CR-91 | ≥91 | <8 | <1 | <1 | <0.4 | |

CR-90 | ≥90 | <8.5 | <1.5 | <2 | <0.4 | |

Image

Carbon Additve Low Ash Sulphur for Steelmaking

FAQ:

Carbon Additve Low Ash Sulphur for Steelmaking

Why we adopt carbon additive?

Carbon Additives used as additive in steel making process. It made from well-selected Tai Xi anthracite which is low in content of ash, sulphur, phosphorus, high heat productivity, high chemically activation.

Mainly industry property of it is: instead of traditional pertroleum coal of Carbon Additives, reduce the cost of steelmaking.

Advantage:

Carbon Additve Low Ash Sulphur for Steelmaking

1.High quality and competitive price.

2.Timely delivery.

3.If any item you like. Please contact us.

Your sincere inquiries are typically answered within 24 hours.

- Q:What is the burning point of carbon?

- Generally speaking, the ignition point of charcoal is relatively low, about 300 degrees, and the coal is higher, at 600 - 700 degrees!

- Q:How does carbon dioxide affect the pH of soil?

- Soil pH can be influenced by carbon dioxide through a process known as carbonation. When carbon dioxide dissolves in water, it creates a weak acid called carbonic acid (H2CO3). This acid can react with certain minerals and compounds, such as limestone or calcium carbonate, found in the soil, causing them to dissolve. As a result, positively charged ions like calcium (Ca2+) or magnesium (Mg2+) are released into the soil solution, which can raise the pH or make the soil more alkaline. Moreover, the presence of carbonic acid can also increase the availability of specific nutrients in the soil. For instance, it can enhance the solubility of phosphorus, making it easier for plants to absorb. This can ultimately improve soil fertility. However, it's important to consider that the impact of carbon dioxide on soil pH can vary due to different factors, including the concentration of carbon dioxide, soil type, and the presence of buffering agents. In some cases, the soil's buffering capacity can limit the effects of carbonic acid on pH changes. Therefore, while carbon dioxide can influence soil pH, it is just one of many factors that can affect the overall acidity or alkalinity of the soil.

- Q:Paint paint fluorocarbon paint which expensive?

- Teflon (Tie Fulong) coating is a kind of high performance coating is the one and only, with heat resistance, chemical inertness and excellent insulation stability and low friction, the comprehensive advantages with other coatings can not compete, the flexibility makes it can be used in almost all the shape and size of the products.Fluorocarbon paint is a kind of coating with fluorine resin as its main film forming material. It is also called fluorocarbon paint, fluorine coating and fluorine resin coating. In a variety of coating, fluorocarbon resin coatings due to the introduction of fluorine element electronegativity, fluorocarbon bond energy, has the good performance. Weather resistance, heat resistance, low temperature resistance, chemical resistance, but also has a unique non sticky and low friction.

- Q:How does carbon impact the prevalence of earthquakes?

- Carbon does not directly impact the prevalence of earthquakes. Earthquakes are primarily caused by the movement of tectonic plates, which are massive sections of the Earth's crust that float on the semi-fluid layer underneath. When these plates collide, slide past each other, or separate, it can cause a release of energy in the form of seismic waves, resulting in an earthquake. Carbon, on the other hand, is a chemical element that is present in various forms in the Earth's atmosphere, oceans, and living organisms. While carbon dioxide (CO2) emissions from human activities contribute to climate change and affect the Earth's ecosystems, there is no direct link between carbon emissions and the prevalence of earthquakes. However, it is worth noting that some geologists and scientists speculate that human activities, such as the extraction of fossil fuels, may indirectly influence seismic activity. The extraction of large quantities of oil, gas, or water from the Earth's crust can potentially lead to changes in the underground pressure and stress distribution, which might trigger small-scale seismic events known as induced earthquakes. These induced earthquakes are typically of low magnitude and are localized to the area where the extraction is taking place. Overall, while carbon emissions and human activities may have some impact on seismic activity in specific localized areas, the prevalence of earthquakes on a global scale is primarily driven by tectonic plate movements and not directly influenced by carbon.

- Q:How does carbon affect the formation of tornadoes?

- Carbon does not directly affect the formation of tornadoes. Tornadoes are primarily caused by the interaction of warm, moist air from the surface and cold, dry air from the upper levels of the atmosphere, resulting in strong updrafts and rotating air columns. Carbon, as an element, does not play a significant role in this process. However, indirectly, carbon emissions and human-induced climate change can impact the overall weather patterns, including the frequency and intensity of tornadoes. Increased carbon dioxide in the atmosphere, primarily from the burning of fossil fuels, contributes to global warming. This, in turn, leads to changes in temperature and moisture patterns, which can influence the conditions conducive to tornado formation. The warming of the atmosphere due to increased carbon dioxide levels can lead to more instability in the atmosphere, creating favorable conditions for severe thunderstorms, which can spawn tornadoes. Additionally, the increased moisture content in the warmer atmosphere can provide more fuel for these storms, potentially enhancing their strength. It is important to note, however, that the relationship between carbon emissions and tornadoes is complex and still an area of ongoing research. While a connection between climate change and tornadoes is plausible, it is challenging to attribute individual tornadoes to carbon emissions alone, as tornadoes are influenced by various meteorological factors. In summary, carbon does not directly impact the formation of tornadoes, but the increased carbon emissions and resulting climate change can indirectly influence the conditions that contribute to tornado formation. Further scientific research is needed to fully understand the relationship between carbon emissions, climate change, and tornado activity.

- Q:What is carbon offsetting in the energy sector?

- Carbon offsetting in the energy sector refers to the practice of balancing out the release of carbon emissions into the atmosphere by investing in projects that reduce or remove an equivalent amount of carbon dioxide from the atmosphere. It aims to neutralize the environmental impact of energy production and consumption by supporting renewable energy projects, reforestation efforts, or other initiatives that reduce greenhouse gas emissions.

- Q:What can light hydrocarbon carbon five be packed with?

- Light hydrocarbon carbon fiveLight hydrocarbon carbon five is a light yellow or colorless transparent flammable liquid with a density of 0.60-0.68 and a boiling point of 36.1 degrees. The calorific value of liquid light hydrocarbons is 10800kcal/kg. (the current price in Chengdu is 2000 yuan / ton, and the monthly supply is about 1000 tons.).

- Q:What are the impacts of carbon emissions on glacier retreat?

- Carbon emissions have a significant impact on glacier retreat. As carbon dioxide and other greenhouse gases are released into the atmosphere through human activities, such as burning fossil fuels and deforestation, they contribute to global warming. This increase in global temperatures has a direct effect on glaciers. Glaciers are large bodies of ice that form over long periods of time from accumulated snowfall. They act as natural reservoirs of freshwater, providing a crucial source of drinking water to millions of people around the world. However, as the Earth's temperature rises due to carbon emissions, glaciers begin to melt at an accelerated rate. The warming climate causes glaciers to lose more ice through melting than they gain through snowfall. This leads to a net loss of ice, resulting in glacier retreat. As glaciers retreat, they not only shrink in size but also become thinner. This diminishes their ability to store water, affecting water availability in regions that rely on glacial meltwater for drinking, irrigation, and hydropower generation. Furthermore, glacier retreat has far-reaching consequences for ecosystems and biodiversity. Glaciers provide unique habitats for various species, including plants, animals, and microorganisms, which have adapted to survive in these extreme environments. As glaciers disappear, these species are forced to adapt or migrate to other areas, disrupting the delicate balance of ecosystems. The impacts of glacier retreat are not limited to local or regional scales. Glacial meltwater contributes to rivers and lakes, ensuring a consistent flow of water throughout the year. As glaciers shrink, this flow decreases, leading to water scarcity during dry seasons. This poses a threat to agriculture, urban water supplies, and the overall sustainability of ecosystems that rely on a stable water supply. Additionally, the loss of glaciers contributes to rising sea levels. When glaciers melt, the water they release flows into the oceans, causing them to expand. This exacerbates coastal erosion, increases the risk of flooding in low-lying areas, and threatens coastal communities and infrastructure. In summary, carbon emissions have a profound impact on glacier retreat. The resulting global warming accelerates the melting of glaciers, leading to water scarcity, biodiversity loss, increased sea levels, and various environmental and socio-economic consequences. It is crucial to address carbon emissions and take steps to mitigate climate change to preserve these vital ice formations and the ecosystems and communities that depend on them.

- Q:How do forests act as carbon sinks?

- Forests act as carbon sinks by absorbing carbon dioxide from the atmosphere through the process of photosynthesis. Trees and other plants take in carbon dioxide and convert it into oxygen, while storing the carbon in their trunks, branches, and roots. This stored carbon remains in the forest ecosystem, reducing the amount of greenhouse gases in the atmosphere and helping to mitigate climate change.

- Q:What is the difference in carbon content of low carbon steel, medium carbon steel and high carbon steel?

- Carbon content of low carbon steel (AISI1005 ~ 1026) is 0.06% to 0.28%, manganese content is 0.25% to 1%, phosphorus content is not more than 0.04%, sulfur content is not more than 0.05%.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Carbon Additve Low Ash sulphur for Steelmaking

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products