Carbon Additive Low Ash Low Sulphur Description

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

Place of Origin: Ningxia, China (Mainland)

Application: steel making

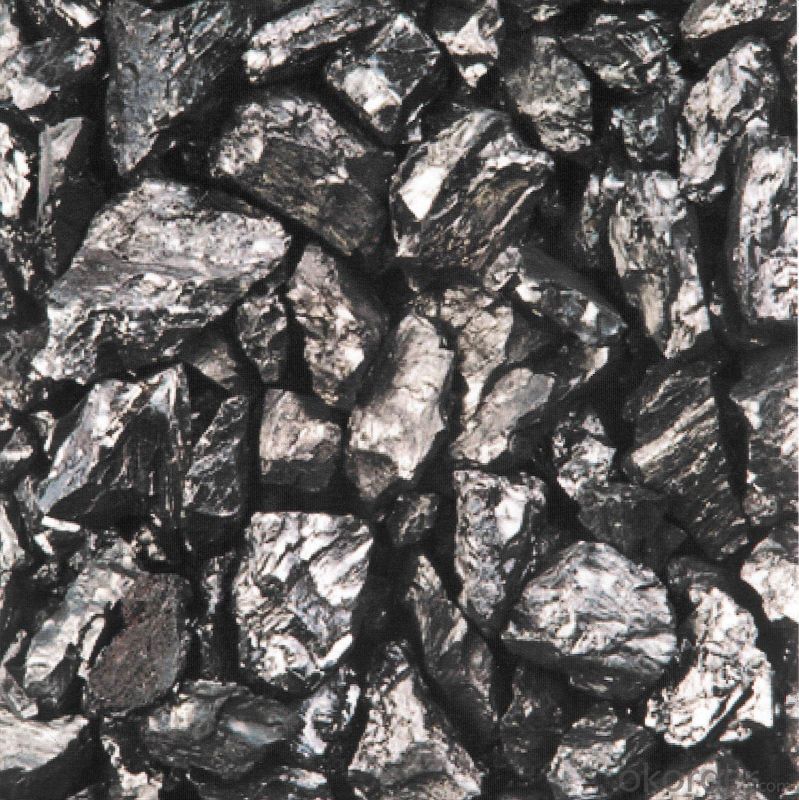

Shape: granule

Dimensions: FC90-95%

Product Type: Carbon Additive

C Content (%): 90-95% MIN

Working Temperature: -

S Content (%): 0.5%MAX

N Content (%): -

H Content (%): 0.6%MAX

Ash Content (%): 8.5%MAX

Volatile: 2%MAX

ADVANTAGE: low ash & sulfur

COLOR: Black

RAW MATERIAL: TaiXi anthracite

Packaging & Delivery

| Packaging Details: | In 1MT plastic woven bag. |

|---|---|

| Delivery Detail: | 30-40DAYS |

Specifications

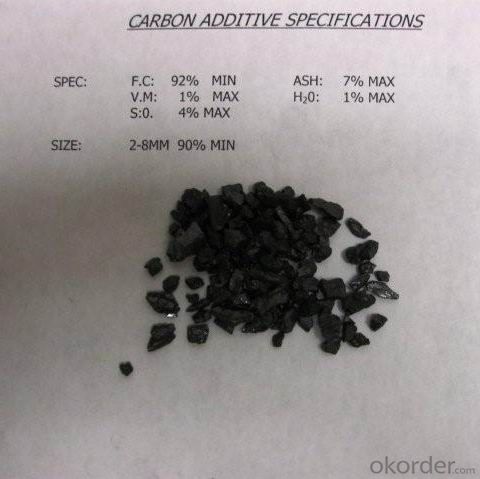

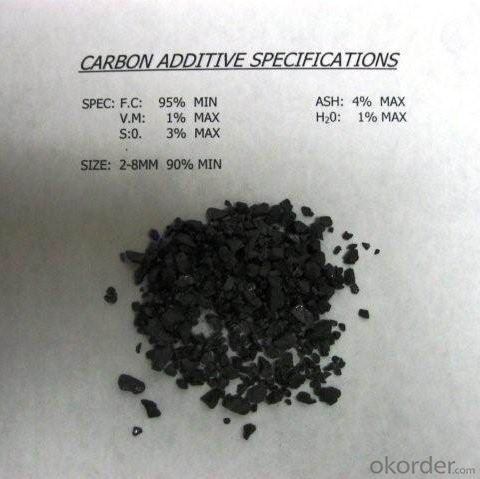

Carbon Additive Low Ash Low Sulfur Specifications

Carbon Additve low Ash,S,P

FC>95% ASH<4% S<0.3%

It is made from TaiXi anthracite.

instead of pertrol coke reduce the cost

Structure

Carbon Additive Low Ash Low Sulfur Specifications

Shape: granule

Dimensions: FC90-95%

Product Type: Carbon Additive

C Content (%): 90-95% MIN

Working Temperature: -

S Content (%): 0.5%MAX

N Content (%): -

H Content (%): 0.6%MAX

Ash Content (%): 8.5%MAX

Volatile: 2%MAX

ADVANTAGE: low ash & sulfur

COLOR: Black

RAW MATERIAL: TaiXi anthracite

..

Feature

Carbon Additive Low Ash Low Sulfur Specifications

| Specifications (%): | ||||||

| Grade | F.C | Ash | V.M | Moisture | S | Size |

| CR-95 | ≥95 | <4< td=""> | <1< td=""> | <1< td=""> | <0.3< td=""> | 0-30mm As buyer's request. |

| CR-94 | ≥94 | <4< td=""> | <1< td=""> | <1< td=""> | <0.3< td=""> | |

| CR-93 | ≥93 | <6< td=""> | <1< td=""> | <1< td=""> | <0.4< td=""> | |

| CR-92 | ≥92 | <7< td=""> | <1< td=""> | <1< td=""> | <0.4< td=""> | |

| CR-91 | ≥91 | <8< td=""> | <1< td=""> | <1< td=""> | <0.4< td=""> | |

| CR-90 | ≥90 | <8.5< td=""> | <1.5< td=""> | <2< td=""> | <0.4< td=""> | |

Image

Carbon Additive Low Ash Low Sulfur Specifications

FAQ:

Why we adopt carbon additive?

Carbon Additives used as additive in steel making process. It made from well-selected Tai Xi anthracite which is low in content of ash, sulphur, phosphorus, high heat productivity, high chemically activation.

Mainly industry property of it is: instead of traditional pertroleum coal of Carbon Additives, reduce the cost of steelmaking.

Advantage:

Carbon Additive Low Ash Low Sulfur Specifications

1.High quality and competitive price.

2.Timely delivery.

3.If any item you like. Please contact us.

Your sincere inquiries are typically answered within 24 hours.

- Q:How does carbon impact the fertility of soil?

- Soil fertility relies heavily on carbon, which serves as the foundation for organic matter. Organic matter, derived from decaying plant and animal residues, enhances the soil's structure, nutrient-holding capacity, and water retention. This results in improved support for plant growth and microbial activity. Not only does organic matter supply carbon, but it also provides nutrients to plants through the process of decomposition. Microorganisms, fungi, and bacteria decompose organic matter and release nutrients like nitrogen, phosphorus, and potassium into the soil. These nutrients become available for plants to absorb. Additionally, carbon in organic matter binds soil particles, preventing erosion and improving soil structure. Furthermore, carbon plays a crucial role in water management for plants. It acts as a sponge, absorbing and retaining moisture, which helps sustain plant growth during dry periods. Carbon also fosters the growth of a diverse and healthy microbial community in the soil, including beneficial bacteria and fungi. These microorganisms contribute to nutrient cycling, disease suppression, and plant nutrient uptake, further enhancing soil fertility. However, it is important to avoid excessive carbon inputs or improper land management practices, as they can negatively affect soil fertility. An imbalance in carbon availability can lead to nitrogen immobilization, where microorganisms consume nitrogen for their own growth, depriving plants of this essential nutrient. Additionally, high carbon content can create anaerobic conditions, limiting oxygen availability for plant roots and beneficial soil organisms. To ensure optimal soil fertility, it is crucial to maintain a balanced carbon-to-nitrogen ratio and adopt sustainable land management practices. Carbon is an indispensable component for maintaining soil health by improving structure, nutrient availability, water retention, and microbial activity.

- Q:The dangers of grilled BBQ on humansWhat are the dangers of a charcoal barbecue?

- Many people may be skeptical - burnt food really carcinogenic? The American Cancer Society will actively publicly called for "eat barbecue foods, because according to the result of medical research, a piece of a pound (about three steaks) barbecue steak, enough to produce carcinogenic substances the equivalent of six hundred cigarettes, which is one reason why many people do not smoke get lung cancer.According to animal experiment confirms that burnt food can lead to animal cancer.

- Q:What are the advantages of carbon-based batteries?

- Carbon-based batteries, such as alkaline batteries, have become a popular choice in various applications due to their numerous advantages. Firstly, their longer shelf life sets them apart from other battery types. They have the ability to retain their charge for extended periods, making them particularly suitable for devices that are infrequently used or for emergency situations. In addition, carbon-based batteries offer a higher energy density, enabling them to store more energy in a compact package. This makes them lightweight and convenient for portable electronic devices like smartphones, laptops, and cameras. Moreover, these batteries have a lower self-discharge rate, meaning they lose less charge over time when not in use. As a result, they can maintain their power for longer periods without the need for frequent recharging or replacement. Furthermore, carbon-based batteries possess a higher discharge rate, allowing them to deliver power quickly when required. This is especially advantageous for devices that demand a sudden burst of energy or for high-drain applications like digital cameras or power tools. Another notable advantage of carbon-based batteries is their cost-effectiveness. They are readily available, inexpensive to produce, and can be easily recycled, thereby reducing their environmental impact. In conclusion, carbon-based batteries offer a range of benefits, including a longer shelf life, higher energy density, lower self-discharge rate, higher discharge rate, cost-effectiveness, and environmental friendliness. These features make them a reliable and efficient choice for a wide array of electronic devices and applications.

- Q:Which is better, 13 and 14 carbon breath tests?

- According to your case, carbon 14 is cheaper than 13, and the accuracy is the same

- Q:What are the different types of carbon-based plastics?

- There are several different types of carbon-based plastics, each with unique properties and applications. Some common types include: 1. Polyethylene (PE): This is the most widely used plastic and can be found in various forms such as high-density polyethylene (HDPE) and low-density polyethylene (LDPE). PE is known for its strength, flexibility, and resistance to chemicals, making it suitable for applications like packaging, pipes, and toys. 2. Polypropylene (PP): PP is another popular plastic known for its high melting point, chemical resistance, and durability. It is commonly used in automotive parts, appliances, and packaging. 3. Polystyrene (PS): PS is a rigid plastic that is often used in disposable products like food containers and packaging materials. It is lightweight and has good insulation properties. 4. Polyvinyl Chloride (PVC): PVC is a versatile plastic that can be rigid or flexible depending on its formulation. It is commonly used in construction materials, pipes, cables, and vinyl flooring. 5. Polyethylene Terephthalate (PET): PET is a strong and lightweight plastic that is commonly used in beverage bottles, food packaging, and textile fibers. It is known for its excellent gas and moisture barrier properties. 6. Polycarbonate (PC): PC is a transparent plastic known for its high impact resistance and heat resistance. It is often used in eyewear, automotive parts, and electronic devices. These are just a few examples of carbon-based plastics, and there are many other variations and blends available in the market. The choice of plastic depends on its intended application, desired properties, and environmental considerations.

- Q:What is carbon neutral manufacturing?

- Carbon neutral manufacturing refers to the process of manufacturing goods while minimizing or offsetting the carbon emissions associated with the production. It involves reducing greenhouse gas emissions at every stage of the manufacturing process, from sourcing raw materials to the disposal of finished products. This can be achieved through various measures such as energy efficiency, the use of renewable energy sources, implementing sustainable practices, and investing in carbon offset projects. To become carbon neutral, manufacturers typically start by conducting a detailed assessment of their carbon footprint, which involves identifying and quantifying all the emissions generated in their operations. This includes direct emissions from manufacturing processes, as well as indirect emissions from the energy sources they use. Once the emissions are measured, manufacturers can develop strategies to reduce their carbon footprint. Some common methods of achieving carbon neutrality in manufacturing include optimizing energy consumption by using efficient equipment and technologies, adopting renewable energy sources like solar or wind power, and implementing waste reduction and recycling programs. Additionally, manufacturers can invest in carbon offset projects, which are initiatives that reduce or remove greenhouse gas emissions from the atmosphere, such as reforestation or renewable energy projects. By implementing these measures and offsetting any remaining emissions, manufacturers can achieve carbon neutrality. This not only helps combat climate change by reducing the overall carbon footprint but also demonstrates a commitment to sustainability and environmental responsibility. Carbon neutral manufacturing is an important step towards transitioning to a low-carbon economy and creating a more sustainable future.

- Q:How does carbon affect the formation of earthquakes?

- Carbon does not directly affect the formation of earthquakes. Earthquakes are caused by the movement of tectonic plates and the release of accumulated stress in the Earth's crust. Carbon, however, can indirectly influence the frequency and intensity of earthquakes through human activities such as mining and fracking, which can trigger seismic events in certain circumstances.

- Q:What is carbon neutral certification?

- Carbon neutral certification is a recognition given to individuals, organizations, or products that have successfully reduced their carbon footprint to zero by balancing their greenhouse gas emissions with an equivalent amount of carbon offsets or renewable energy. It signifies a commitment to mitigating the negative environmental impact and contributing to a more sustainable future.

- Q:How does carbon impact the availability of renewable energy sources?

- Carbon impacts the availability of renewable energy sources in a number of ways. Firstly, carbon emissions from the burning of fossil fuels contribute to climate change, which is a significant threat to the availability and sustainability of renewable energy sources. The increased frequency and intensity of extreme weather events caused by climate change can damage renewable energy infrastructure, such as wind turbines and solar panels. Secondly, carbon-intensive industries, such as coal mining and oil extraction, can limit the growth and development of renewable energy technologies. These industries have historically received substantial subsidies and support from governments, which can hinder the progress of renewable energy by diverting resources and investment away from cleaner alternatives. Furthermore, carbon emissions contribute to air pollution, which can have negative impacts on the efficiency and performance of renewable energy systems. For example, air pollution can reduce the amount of sunlight reaching solar panels or obstruct wind flow to turbines, thereby decreasing their energy output. Additionally, the reliance on carbon-based energy sources creates a significant market competition for renewable energy. Fossil fuels often have lower costs due to their established infrastructure and economies of scale, making it challenging for renewable energy sources to compete on a cost basis. This can limit the availability and accessibility of renewable energy options, particularly in developing countries where fossil fuels are often the cheaper and more readily available option. To address these challenges, it is crucial to reduce carbon emissions through transitioning to renewable energy sources and implementing policies that incentivize their adoption. By reducing carbon emissions, we can mitigate the impacts of climate change on renewable energy infrastructure and create a more conducive environment for the development and deployment of clean energy technologies.

- Q:What are the applications of carbon nanowires?

- Carbon nanowires have a wide range of applications across various fields due to their unique properties and characteristics. Some of the key applications of carbon nanowires are: 1. Electronics: Carbon nanowires can be used as conducting channels in electronic devices, such as transistors and interconnects. Their high electrical conductivity, small size, and ability to carry high current densities make them ideal for use in nanoelectronics. 2. Energy storage: Carbon nanowires can be utilized in energy storage devices, such as batteries and supercapacitors. Their high surface area and excellent electrical conductivity enable efficient charge and energy storage, leading to enhanced performance and longer life cycles. 3. Sensors: Carbon nanowires can be used as sensing elements in various types of sensors. Their high sensitivity to changes in temperature, pressure, or gas concentration makes them suitable for applications in environmental monitoring, healthcare, and industrial sensing. 4. Biomedical applications: Carbon nanowires show promise in biomedical applications, including drug delivery systems and tissue engineering. They can be functionalized with specific molecules to target and deliver drugs to specific cells or tissues. Additionally, their high mechanical strength and biocompatibility make them suitable for scaffolds in tissue engineering applications. 5. Nanoelectromechanical systems (NEMS): Carbon nanowires can be used to construct NEMS devices, which are miniature mechanical systems that operate at the nanoscale. These devices have applications in sensing, actuation, and data storage, and carbon nanowires provide the necessary mechanical and electrical properties for their operation. 6. Nanocomposites: Carbon nanowires can be incorporated into various materials to enhance their mechanical, electrical, and thermal properties. They can reinforce polymers, ceramics, and metals, leading to improved strength, conductivity, and heat dissipation in the resulting nanocomposites. 7. Optoelectronics: Carbon nanowires can be utilized in optoelectronic devices, such as photodetectors and light-emitting diodes (LEDs). Their high electron mobility, low electrical resistance, and ability to emit light make them suitable for applications in displays, lighting, and optical communications. Overall, the applications of carbon nanowires are diverse and expanding, with the potential to revolutionize fields such as electronics, energy storage, sensing, biomedicine, and more. Continuous research and development in this area are expected to uncover even more exciting applications in the future.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Carbon Additive Low Ash Low Sulphur Description

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches